Rolling treatment device and treatment process for building glass curtain wall

A technology for processing devices and architectural glass, which is applied in construction, building maintenance, building construction, etc. It can solve problems such as improper placement of heavy objects, potential safety hazards, and glass affecting aesthetics, so as to avoid space waste and reduce floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

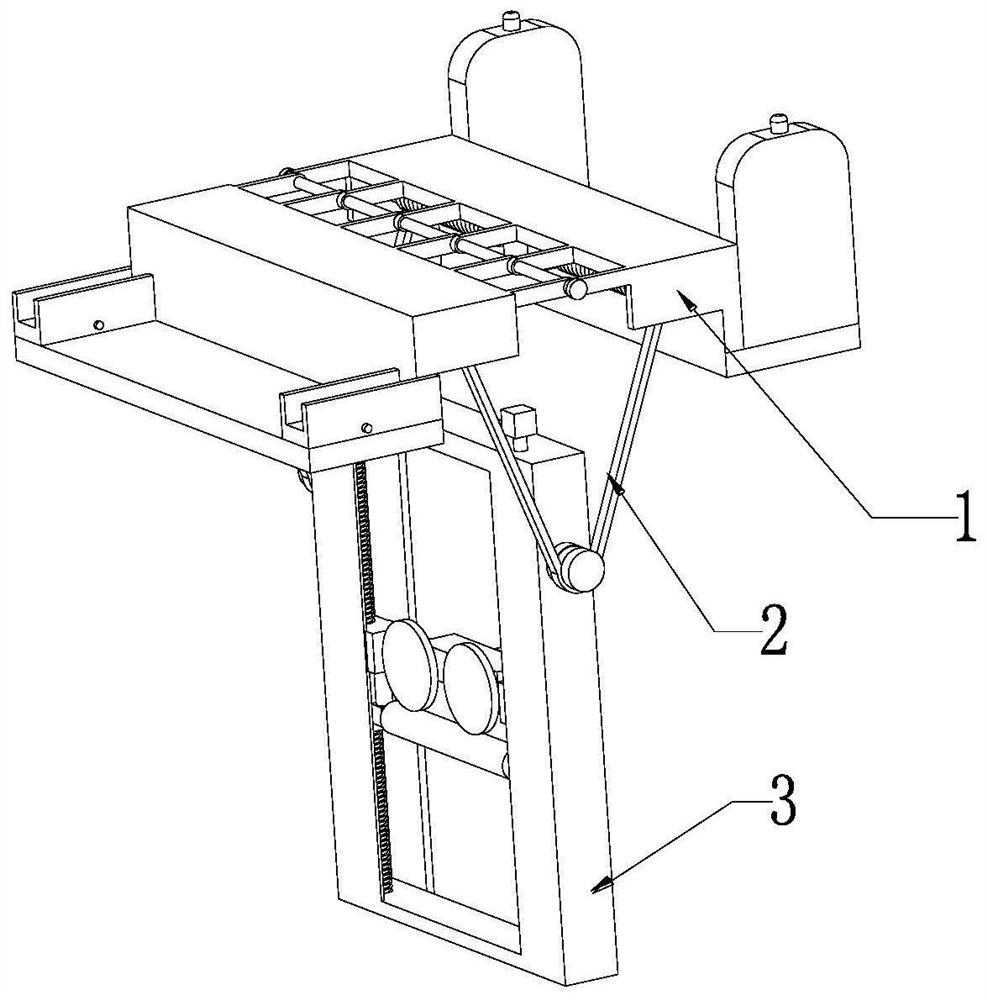

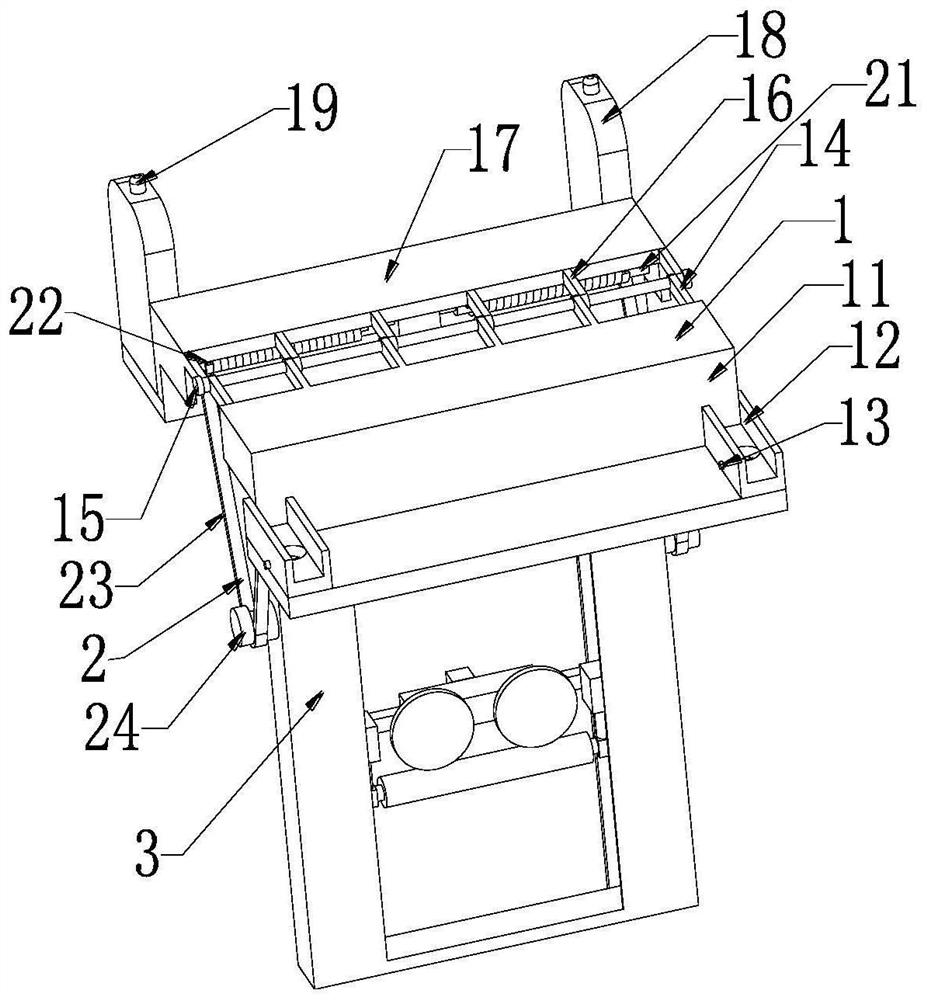

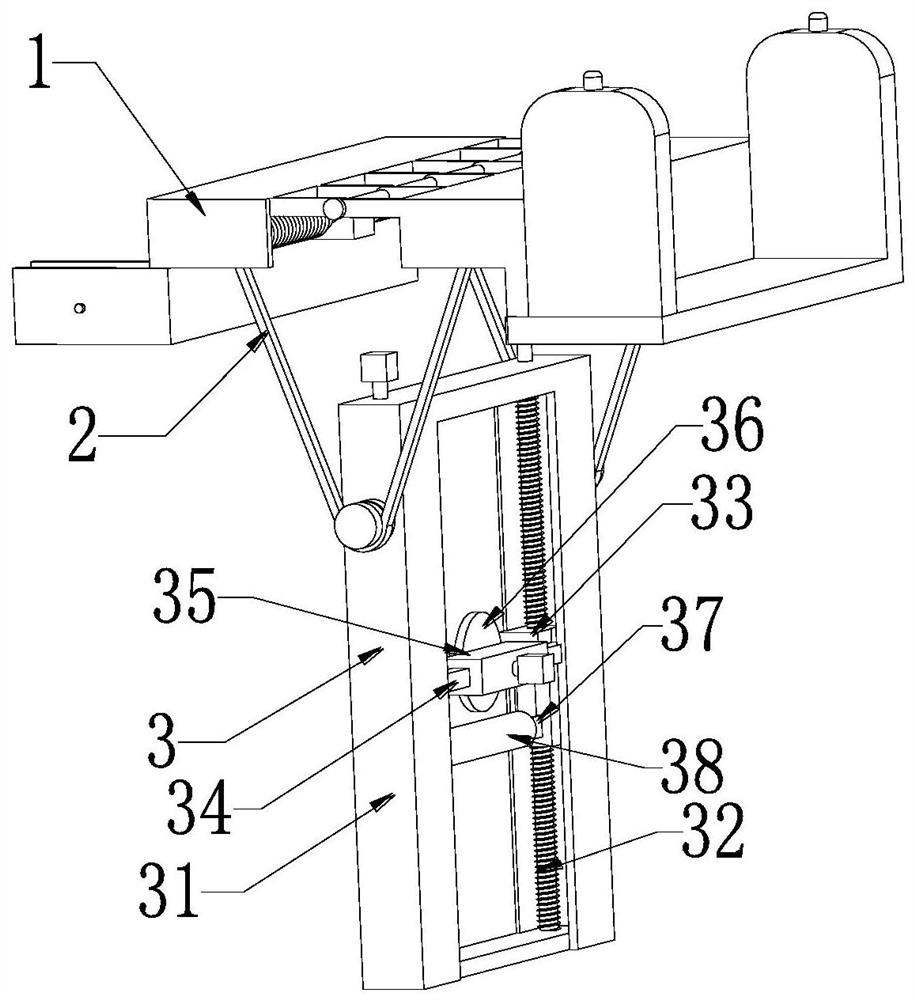

[0032] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand and understand, the following combination Figure 1 to Figure 8 , the present invention will be further elaborated.

[0033] A rolling type processing device for architectural glass curtain wall, comprising a fixing kit 1, a feeding kit 2 and a cleaning kit 3, a feeding kit 2 is arranged at the lower end of the fixing kit 1, and a cleaning kit 3 is arranged inside the feeding kit 2, wherein:

[0034] The fixing kit 1 includes the No. 1 bearing plate 11, the joint seat 12, the reset mechanism 13, the A rotating side plate 14, the rotating shaft 15, the B rotating side plate 16, the No. 2 bearing plate 17, the joint plate 18 and the pin column 19, The No. 1 bearing plate 11 is fixedly installed on the ground. The No. 1 bearing plate 11 has a Z-shaped structure. The left and right sides of the No. 1 bearing plate 11 are symmetrically p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com