Metal transparent electrode and organic solar cell

A solar cell and transparent electrode technology, applied in the field of solar cells, can solve problems such as poor flexibility, high preparation cost, and fragile transparent electrode materials, and achieve high photocurrent, improve light utilization, and improve transmission and collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

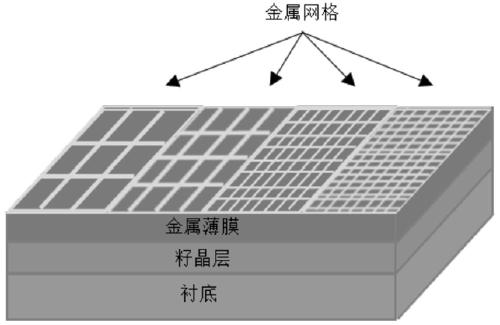

[0032] The glass substrate was ultrasonically cleaned with detergent, isopropanol, ethanol, and acetone in sequence, and dried with nitrogen after cleaning; a ZnO film was prepared on the surface of the glass substrate by spin coating with a thickness of about 45 nm; A layer of 5 nm ultra-thin Ag film was vacuum evaporated on the surface; then the thicknesses of 10 nm, 15 nm, 20 nm, and 25 nm were evaporated on it, and the corresponding inscribed circle diameters were 200 μm, 150 μm, 100 μm, 50 μm, Ag grid with a line width of 5 μm, formed as figure 1 A metallic transparent electrode with a conductivity step distribution shown.

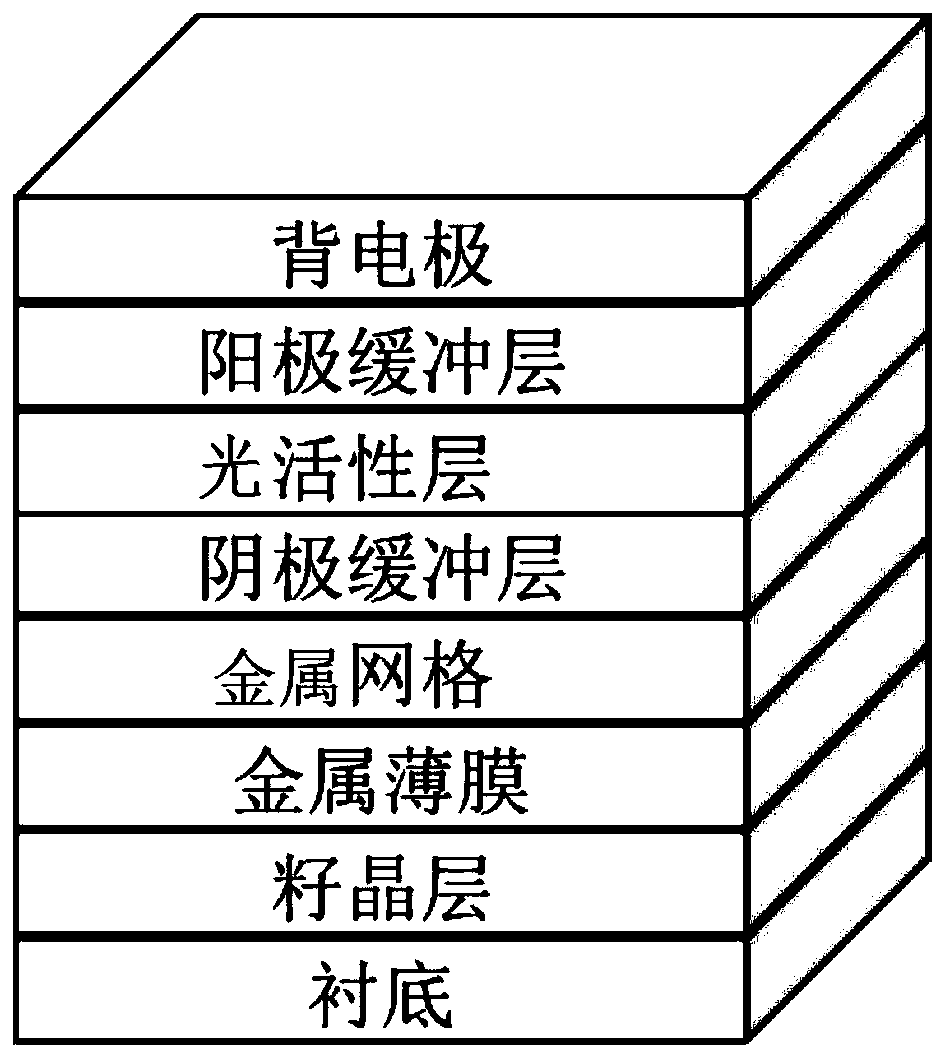

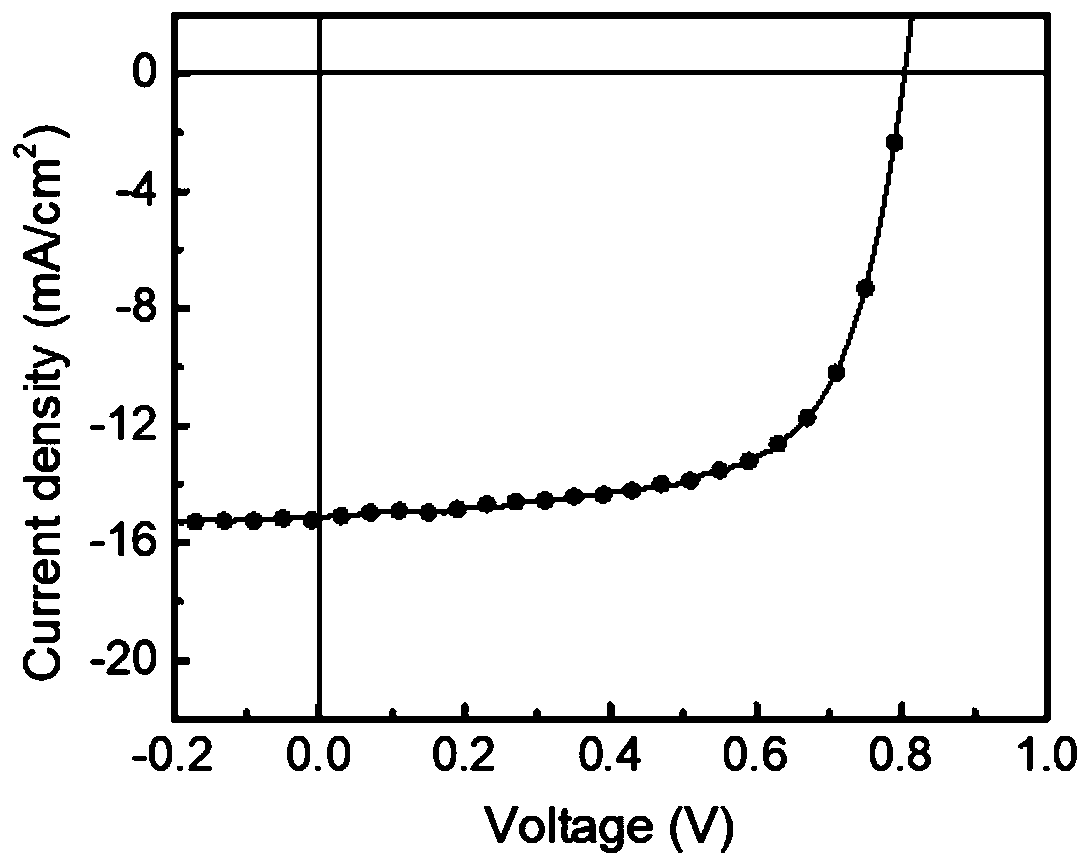

[0033] Spin-coating 30 nm of SnO on the surface of transparent metal electrodes 2 (cathode buffer layer), and anneal the formed film at 150 °C for 10 minutes; then spin-coat PTB7-Th and PC 71 Mixed solution of BM, PTB7-Th and PC 71 The mass ratio of BM was 1:1.5, and a layer of PTB7-Th and PC with a thickness of 90 nm was obtained 71 BM hybrid fil...

Embodiment 2

[0035] The glass substrate was ultrasonically cleaned with detergent, isopropanol, ethanol, and acetone in sequence, and dried with nitrogen after cleaning; MoO was prepared on the surface of the glass substrate by spin coating 3 thin film with a thickness of about 40 nm; then in MoO 3 A layer of 5 nm ultra-thin Au film was vacuum evaporated on the surface of the film; then the thicknesses of 10 nm, 15 nm, 20 nm, and 25 nm were evaporated on it, and the corresponding inscribed circle diameters were 200 μm, 150 μm, and 100 μm , 50 μm, step-structured Ag grid with a line width of 5 μm, formed as figure 1 A metallic transparent electrode with a conductivity step distribution shown.

[0036]Spin-coat 30 nm of Bphen (cathode buffer layer) on the surface of the transparent metal electrode, and anneal the formed film at 150 °C for 10 minutes; then spin-coat P3HT and PC 71 Mixed solution of BM, PTB7-Th and PC 71 The mass ratio of BM was 1:1.5, and a layer of PTB7-Th and PC with a t...

Embodiment 3

[0038] The glass substrate was ultrasonically cleaned with detergent, isopropanol, ethanol, and acetone in sequence, and dried with nitrogen after cleaning; TeO2 was prepared on the surface of the glass substrate by spin coating. 2 thin film with a thickness of about 50 nm; then in TeO 2 A layer of 5 nm ultra-thin Cu film was vacuum-evaporated on the surface of the film; then, the thicknesses of 10 nm, 15 nm, 20 nm, and 25 nm were evaporated on it, and the corresponding inscribed circle diameters were 200 μm, 150 μm, and 100 μm. , 50 μm, step-structured Ag grid with a line width of 5 μm, formed as figure 1 A metallic transparent electrode with a conductivity step distribution shown.

[0039] Spin-coat 30 nm of PFN-Br (cathode buffer layer) on the surface of the transparent metal electrode, and anneal the formed film at 150 °C for 10 minutes; then spin-coat PTB7 and PC 71 Mixed solution of BM, PTB7-Th and PC 71 The mass ratio of BM was 1:1.5, and a layer of PTB7-Th and PC wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com