Explosion-proof locking mechanism for temperature sensor element

A technology of temperature sensor and locking mechanism, which is applied to the parts of thermometers, thermometers, and thermometers with electric/magnetic elements that are directly sensitive to heat. Problems such as expansion and contraction, increased maintenance and replacement costs, etc., achieve the effect of simple structure, convenient and reliable use, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

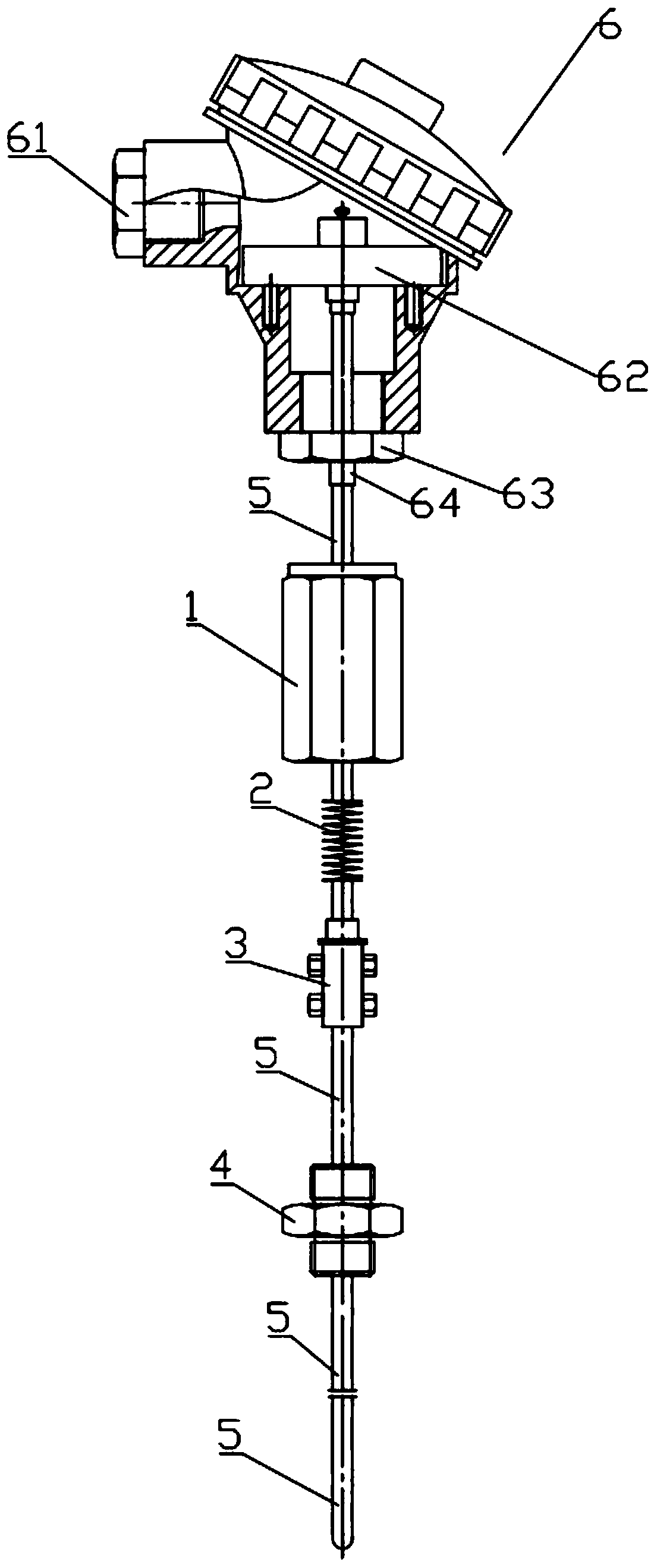

[0031] Such as Figure 1 to 2 As shown, an explosion-proof locking mechanism for a temperature sensor element includes a threaded sleeve 1, a telescopic spring 2, a locking sleeve 3, and a threaded joint 4; when in use, the armored temperature element 5 is inserted through from top to bottom. The threaded sleeve 1, the telescopic spring 2, the locking sleeve 3 and the threaded joint 4, and pass through; the threaded sleeve 1 has a cavity in it, and one end in the axial direction is provided with internal threads for connecting with One end of the threaded joint 4 is connected, and the other end has a baffle 11; the telescopic spring 2 is arranged between the threaded sleeve 1 and the locking sleeve 3, and after installation, it is accommodated in the threaded sleeve 1 In the cavity of, one end is in contact with the baffle 11 and the other end is in contact with the locking sleeve 3; the locking sleeve 3 is provided with at least one threaded hole in the radial direction, and t...

Embodiment 2

[0033] Such as Figure 1 to 2 As shown, an explosion-proof locking mechanism for a temperature sensor element includes a threaded sleeve 1, a telescopic spring 2, a locking sleeve 3, and a threaded joint 4;

[0034] When in use, the armored temperature element 5 is inserted into the threaded sleeve 1, the telescopic spring 2, the locking sleeve 3 and the threaded joint 4 from top to bottom, and passes out;

[0035] The threaded sleeve 1 has a cavity, and one end in the axial direction is provided with an internal thread for connecting with one end of the threaded joint 4, and the other end has a baffle 11;

[0036] The telescopic spring 2 is arranged between the threaded sleeve 1 and the locking sleeve 3, and after installation, it is accommodated in the cavity of the threaded sleeve 1, one end is in contact with the baffle 11, and the other end Contact with the locking sleeve 3;

[0037] The locking sleeve 3 is provided with at least one threaded hole in the radial direction, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com