Flue smoke exhaust system and control method thereof

A smoke exhaust system and flue technology, which is applied in the combustion method, heating method, and oil fume removal, etc., can solve the problems of changing the angle of the valve plate, reducing the smoke exhaust ability of the range hood, and affecting the opening of the valve plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

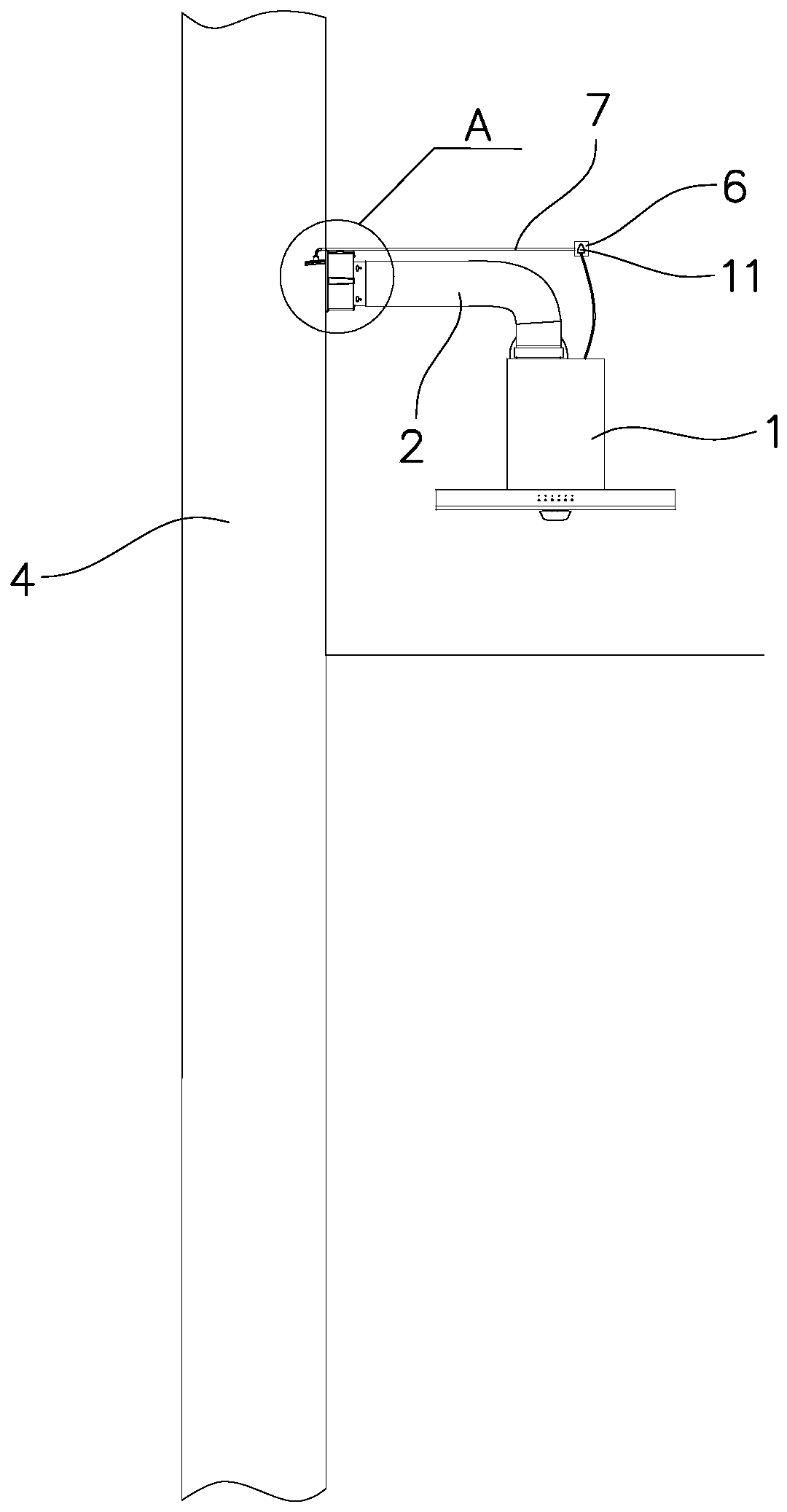

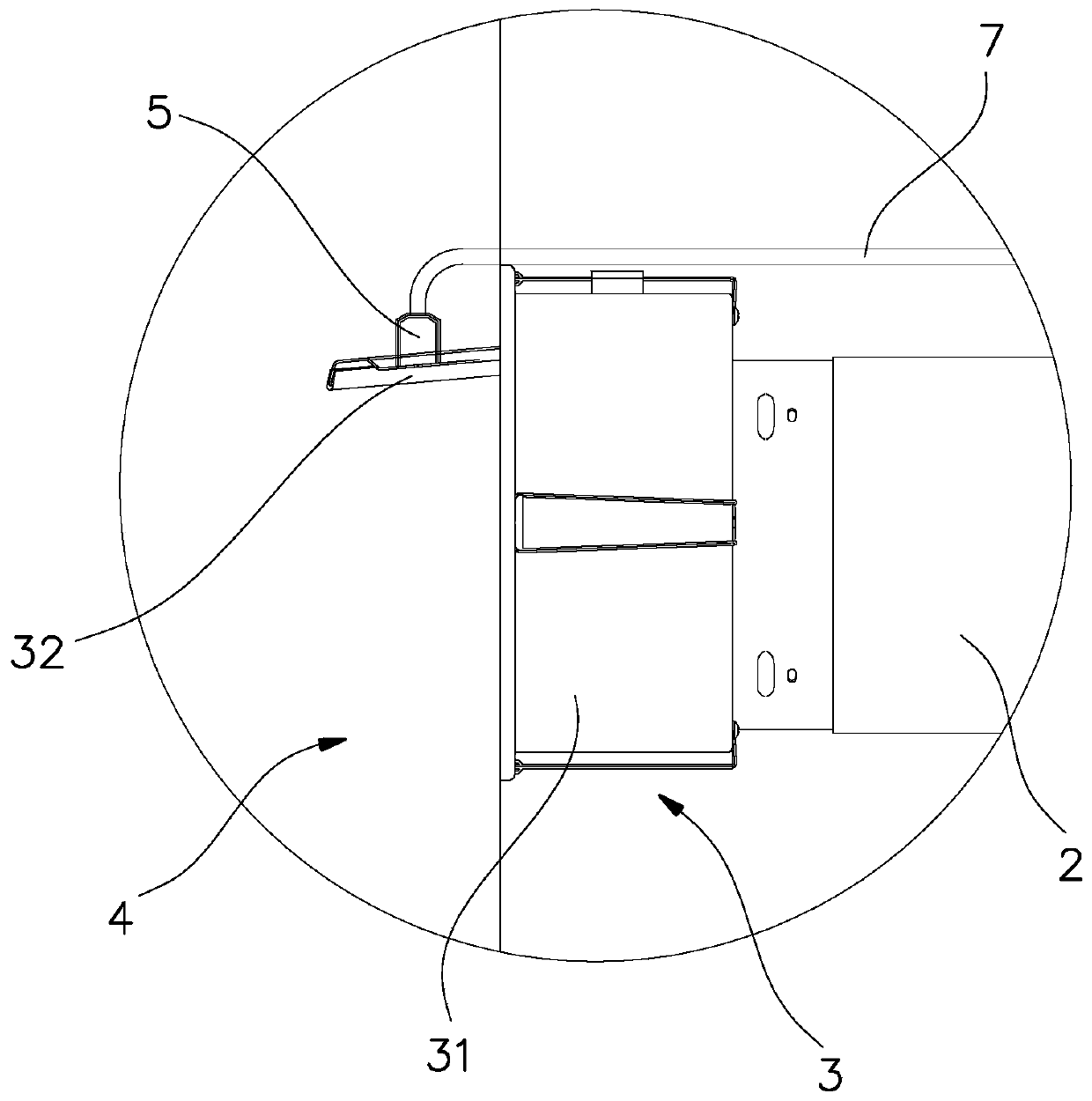

[0032] Such as figure 1 with figure 2 As shown, the flue smoke exhaust system of this embodiment includes a range hood 1 , a smoke pipe 2 , a fire damper 3 , a public flue 4 , an electromagnetic chuck 5 and a power detection socket 6 .

[0033] Among them, the fire damper 3 includes a valve body 31 and a valve plate 32, the valve body 31 is installed on the outlet end of the smoke pipe 2, the valve plate 32 is installed on the valve body 31, and the air outlet of the range hood 1 passes through the smoke pipe 2 and the fire damper in turn. 3 communicates with public flue 4. When the range hood 1 is working, the oil fume generated is discharged into the public flue 4 through the smoke pipe 2 and the fire damper 3 . The above-mentioned structure is the same as the existing flue exhaust system, and will not be described here.

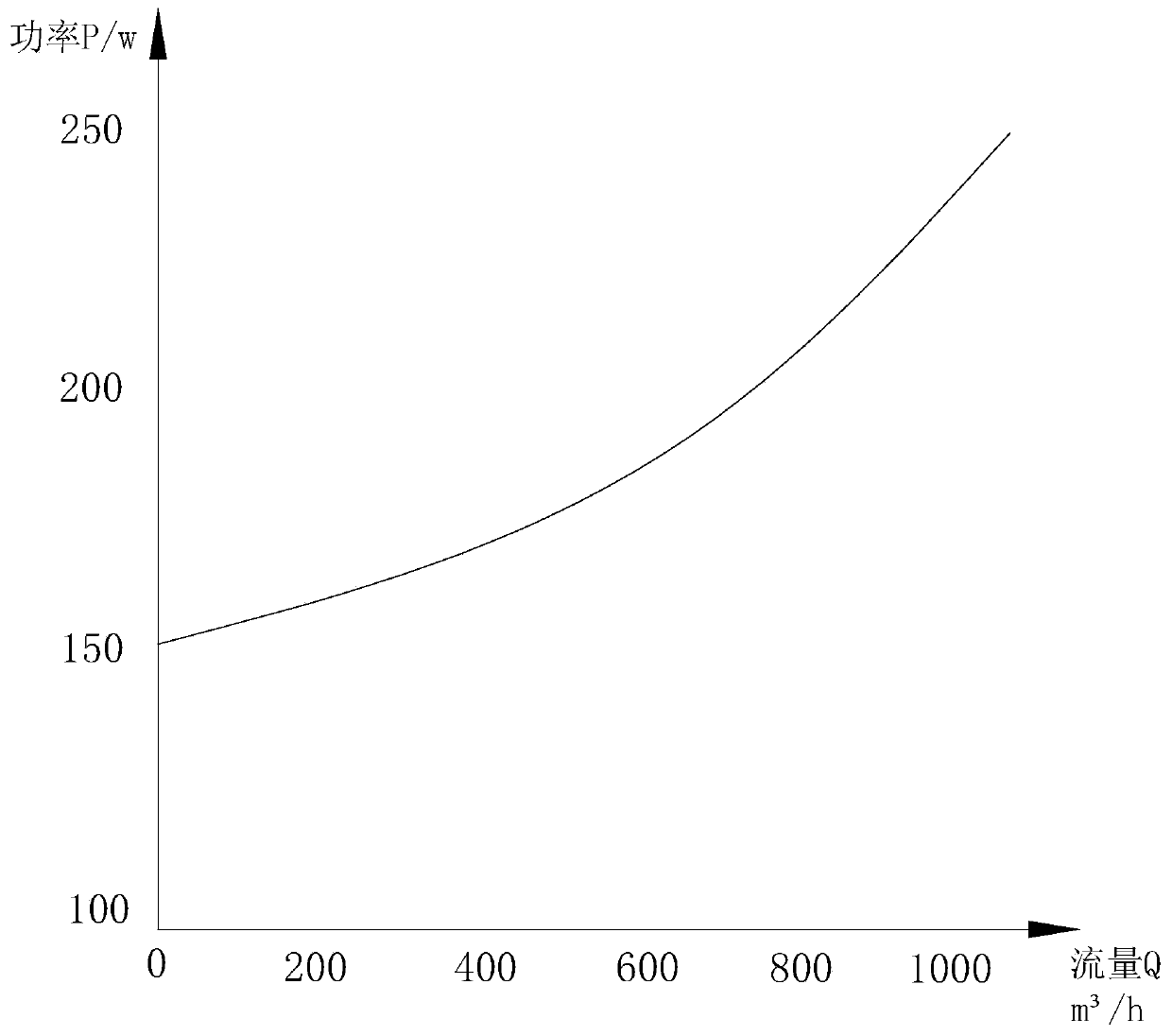

[0034] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com