Tool for clamping minor-caliber optical mirror slip

An optical lens, small-caliber technology, applied in the field of clamping tools, can solve the problems of lens scratches, easy falling off of lenses, reduced production efficiency, etc., and achieves the effects of convenient operation, low cost, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

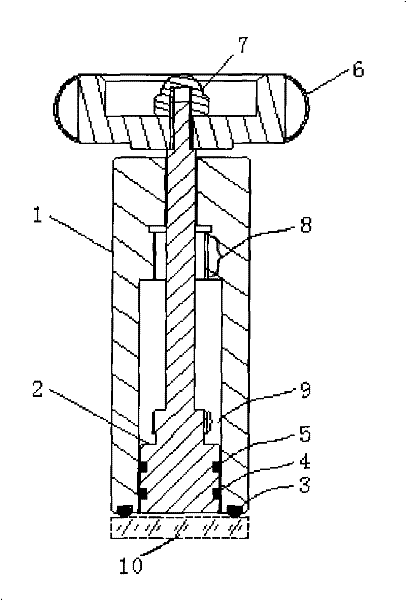

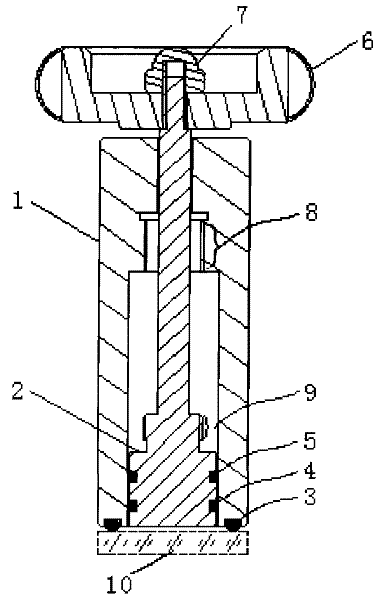

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

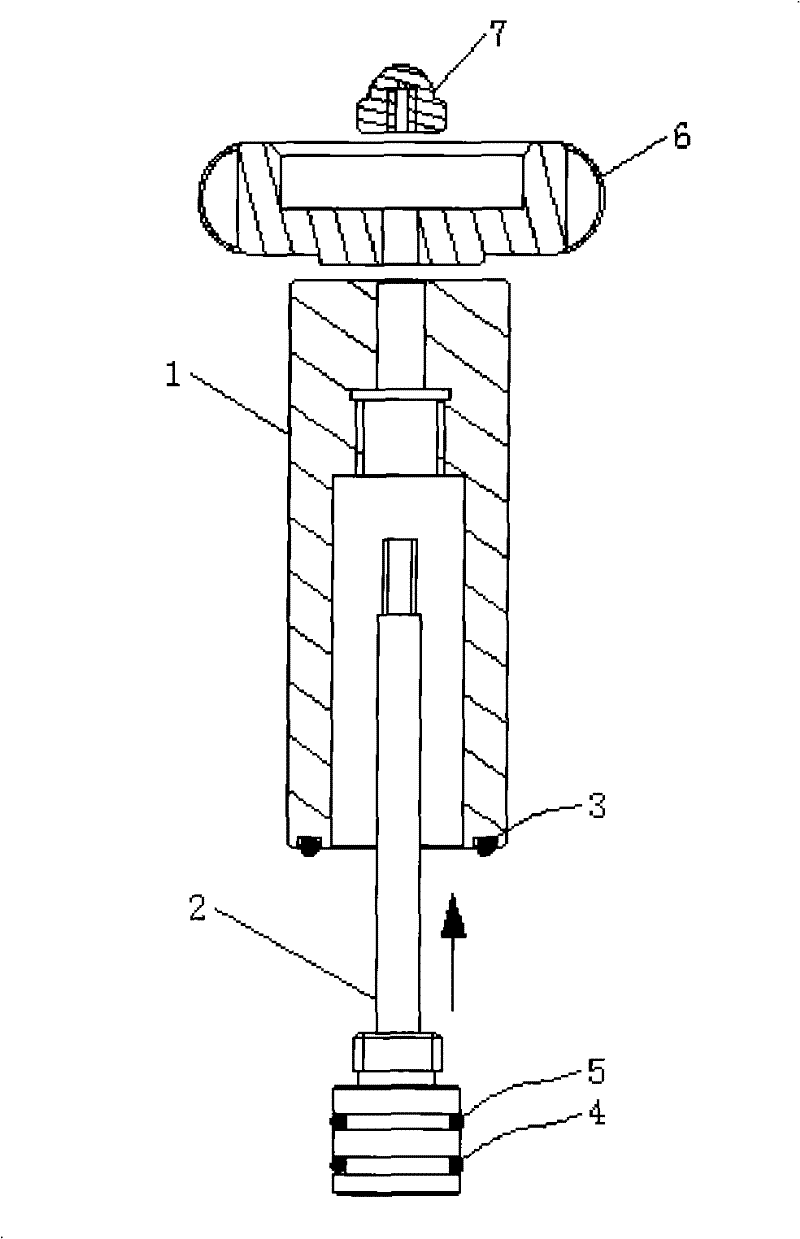

[0026] Reference attached figure 1 , making a clamping tool for clamping small-diameter optical lenses of the present invention.

[0027] This tool comprises a control handle 6, and the control handle 6 adopts metal or engineering plastics (such as polytetrafluoroethylene) to process, and the axial direction processes a hole, and the diameter of this hole should be slightly larger than the thinner end of the piston. The diameter of the external thread that the cap 7 cooperates, and the shape of the handle is processed into a handwheel shape or a spherical shape to facilitate the operator to hold the handle.

[0028] It also includes a sleeve 1, which is processed into a sleeve with a through hole by using metal or engineering plastics (such as polytetrafluoroeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com