Gripping device and method for grabbing products

A grasping device and product technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of product extraction and detachment, uneven panels, and inability to hold products well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

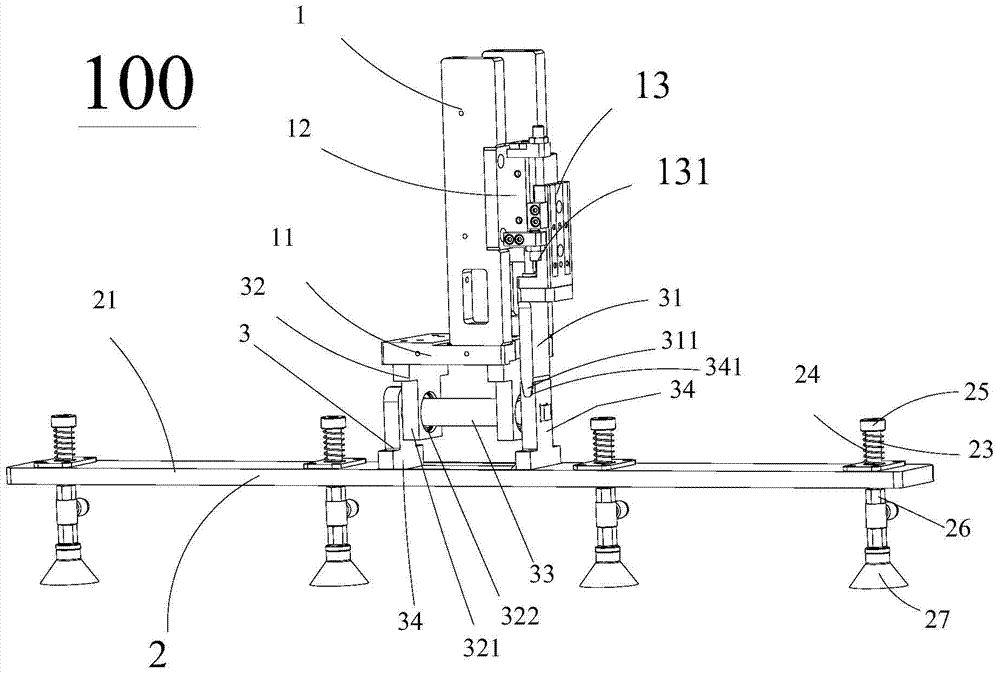

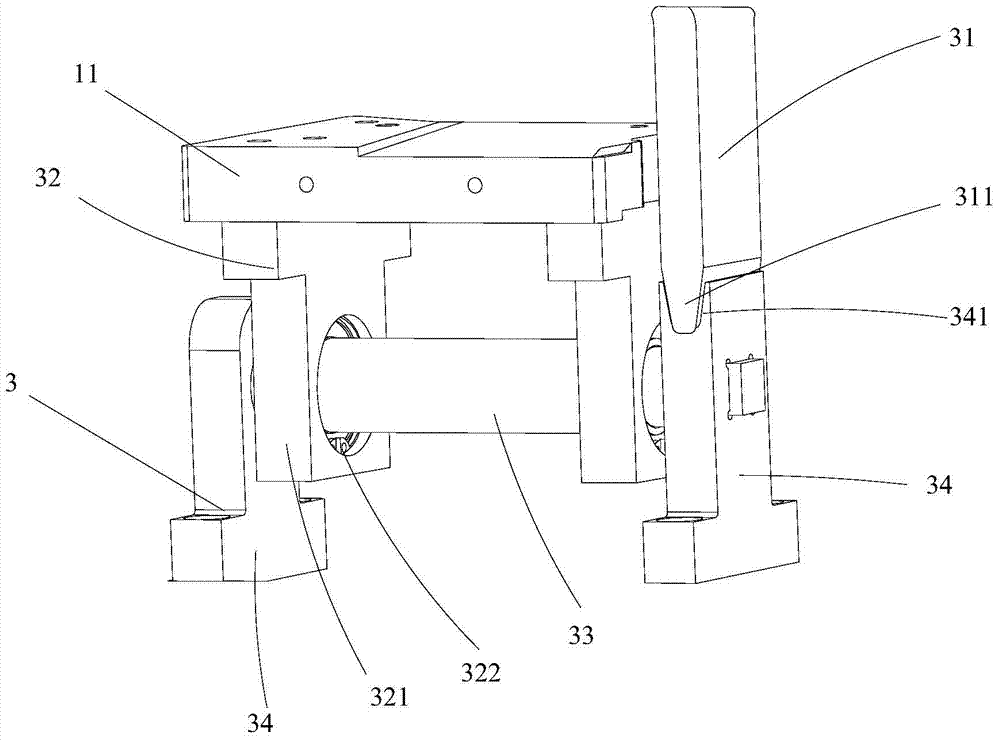

[0020] see Figure 1 to Figure 3 As shown, the present invention discloses a grabbing device 100 for grabbing products, which has a jacking mechanism 1 , a grabbing mechanism 2 and a connecting mechanism 3 connecting the jacking mechanism 1 and the grabbing mechanism 2 .

[0021] Such as figure 1 As shown, the jacking mechanism 1 includes a base 11 , a mount 12 mounted on the base 11 and a cylinder 13 mounted on the mount 12 . The mounting base 12 extends vertically, the air cylinder 13 is fixed on the mounting base 13 , and the output shaft 131 of the air cylinder 13 extends downward.

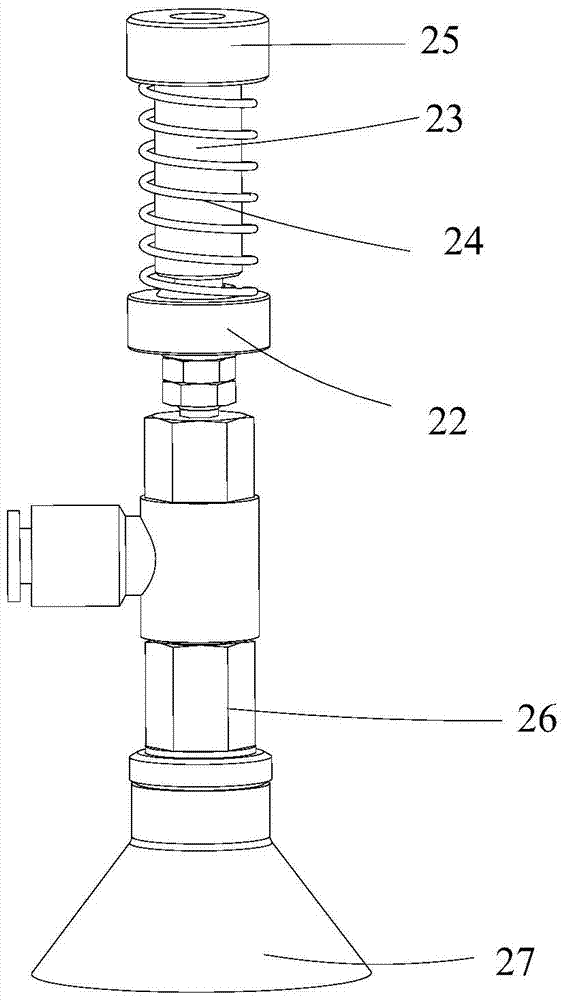

[0022] Such as Figure 1 to Figure 2 As shown, the grabbing mechanism 2 has a fixed plate 21, and a number of storage holes (not indicated) are formed side by side through the upper and lower surfaces of the fixed plate 21. The first bearing 22 is accommodated in the accommodation hole, and the first bearing 22 accommodates a vertically upwardly extending The connection column 23 , a spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com