Interface-fusing, load-optimizing and fault-monitoring high speed train braking system

A technology for fault monitoring and high-speed trains, applied in railway braking systems, braking safety systems, brake types, etc. Train operating efficiency and economic benefits and other issues to achieve the effect of improving braking reliability and safety, ensuring braking reliability and safety, and improving interface heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

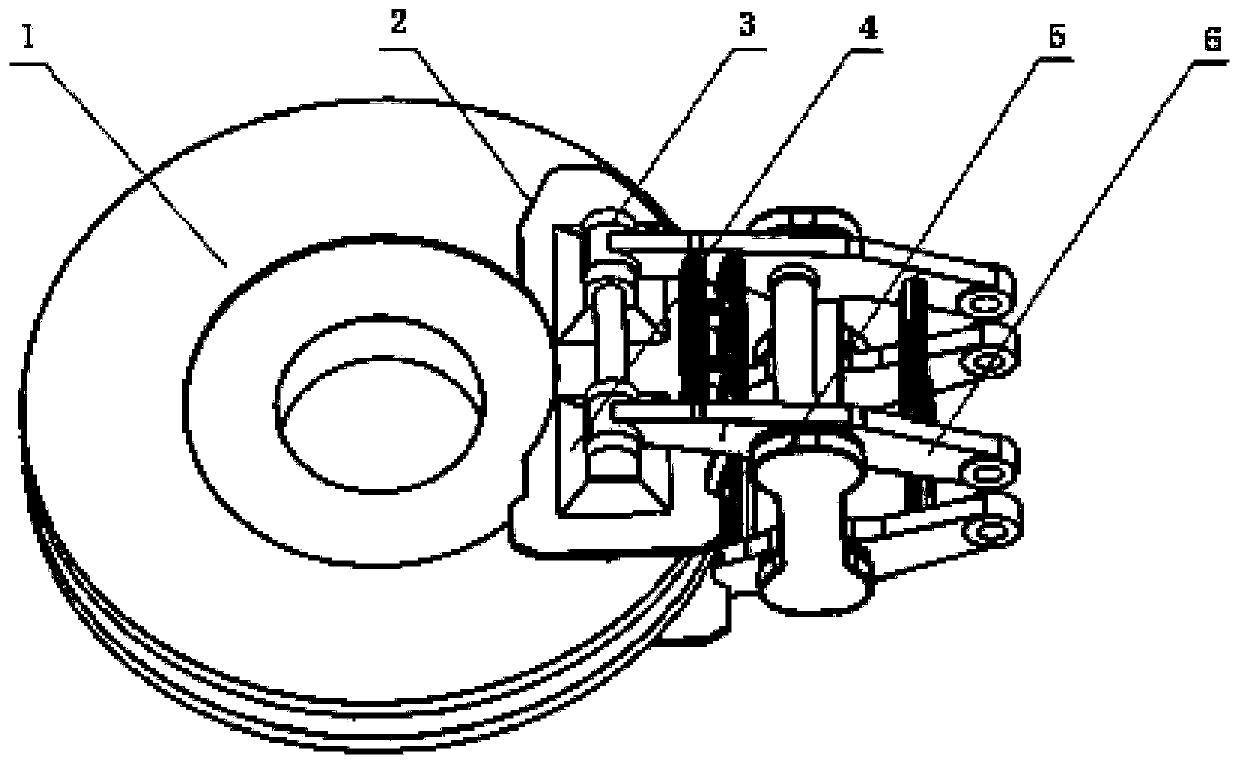

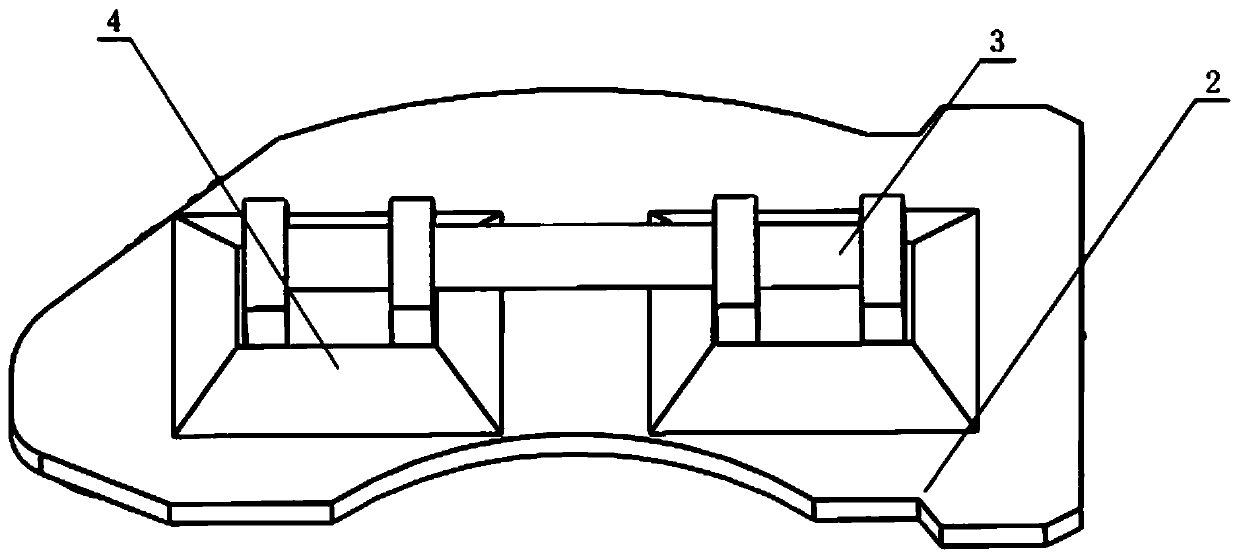

[0055] A high-speed train braking system that integrates interface and loading optimization and fault monitoring, including a brake disc 1, a brake pad structure and a loading device, the loading device is connected to the brake pad structure, and the brake pad structure is connected to the brake pad structure The brake disc 1 cooperates, and the brake pad structure includes a brake pad back plate 2, and several friction particles 7 are arranged on the brake pad back plate 2, and the several friction particles 7 adopt several kinds of surfaces grooming. The several surface modifications described above include opening holes, chamfering or ditching on the surface of the friction particles 7 . In this embodiment, friction particles 7 with two surface modifications, chamfered and open, are used. In this embodiment, the structure of the brake pad back plate 2 is left-right symmetrical, and its shape is arc-like, and it is stamped and formed by steel material.

[0056] Such as ...

Embodiment 2

[0065] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

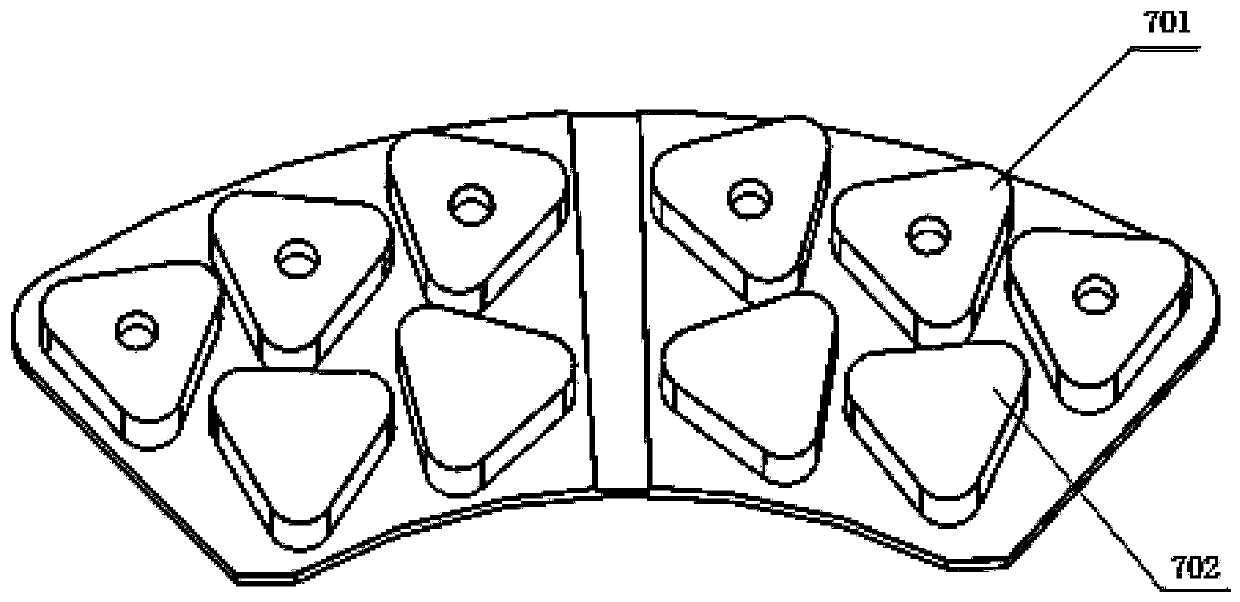

[0066] Such as Figure 4 As shown, in the present embodiment, the number of friction particles 7 is ten, and four of them are porous friction particles 701. Non-porous friction particles 702, the shape of the non-porous friction particles 702 is triangular and only the surface is modified by chamfering. The four porous friction particles 701 are located at the cutting end of the brake pad back plate 2 (ie, the end facing the cutting direction), and the six non-porous friction particles 702 are located at the middle of the brake pad back plate 2 .

[0067] The intelligent monitoring system added to the brake system can also collect the temperature rise change signal of the contact interface between the friction particles 7 and the brake disc 1 . A temperature sensor is arranged on the brake pad back plate 2, and is used to collect the temperature rise chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com