Micro-nano particle nondestructive carrying method and device based on controllable micro-scale bubbles

A micro-nano particle, micro-scale technology, applied in enzymology/microbiology devices, tissue cell/virus culture devices, biochemical cleaning devices, etc. , to achieve a reliable release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

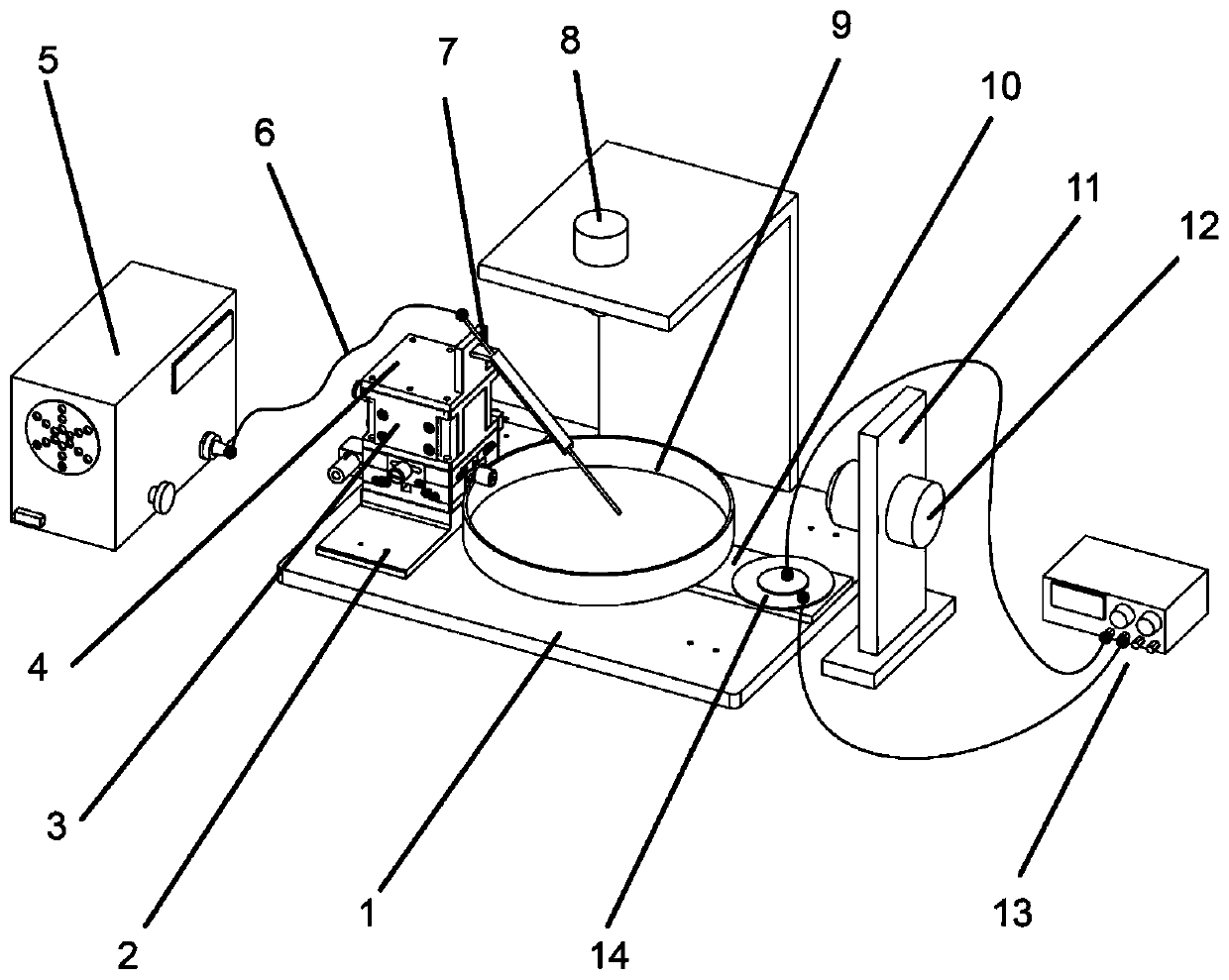

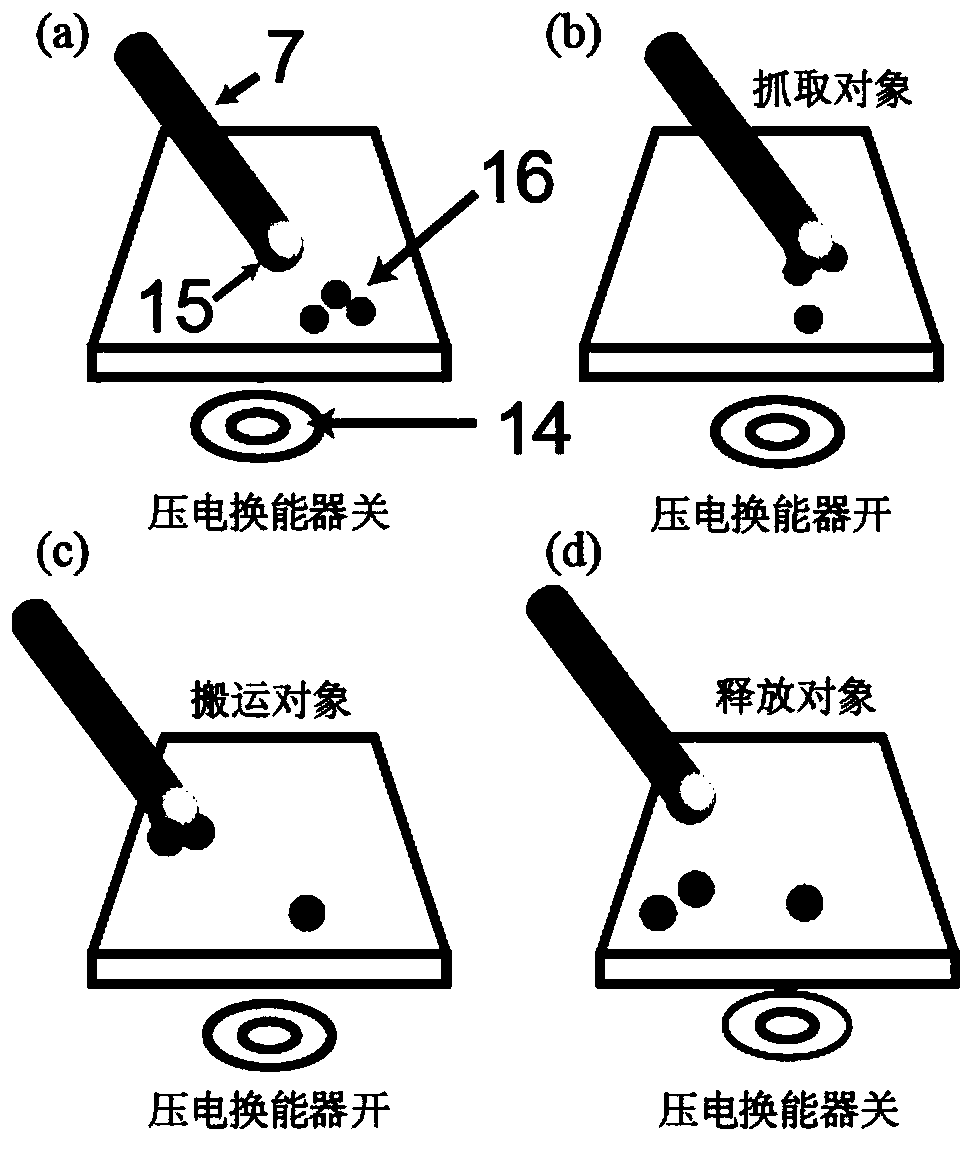

[0042] Combine below figure 1 , figure 2 Description of this embodiment

[0043] A non-destructive transport device for micro-nano particles includes an optical microscope platform 1, a No. 1 fixed connecting plate 2 fixed on the scientific microscope platform 1, and a three-degree-of-freedom precision mobile platform 3 fixed on the No. 1 fixed connecting plate 2 . The capillary 7 for micro-nano operation is fixed on the three-degree-of-freedom precision mobile platform 3 through the second fixed connection plate 4 , and is connected with the air pressure generator and the controller 5 through the connecting pipe 6 . Both the petri dish 9 and the disc-shaped piezoelectric transducer 14 are fixedly connected to the operation base plate 10 . The operation bottom plate 10 is placed on the optical microscope platform 1 and is located below the micro-nano operation capillary 7 . The disk-shaped piezoelectric transducer 14 is connected to the signal generator 13 through a line. ...

Embodiment 2

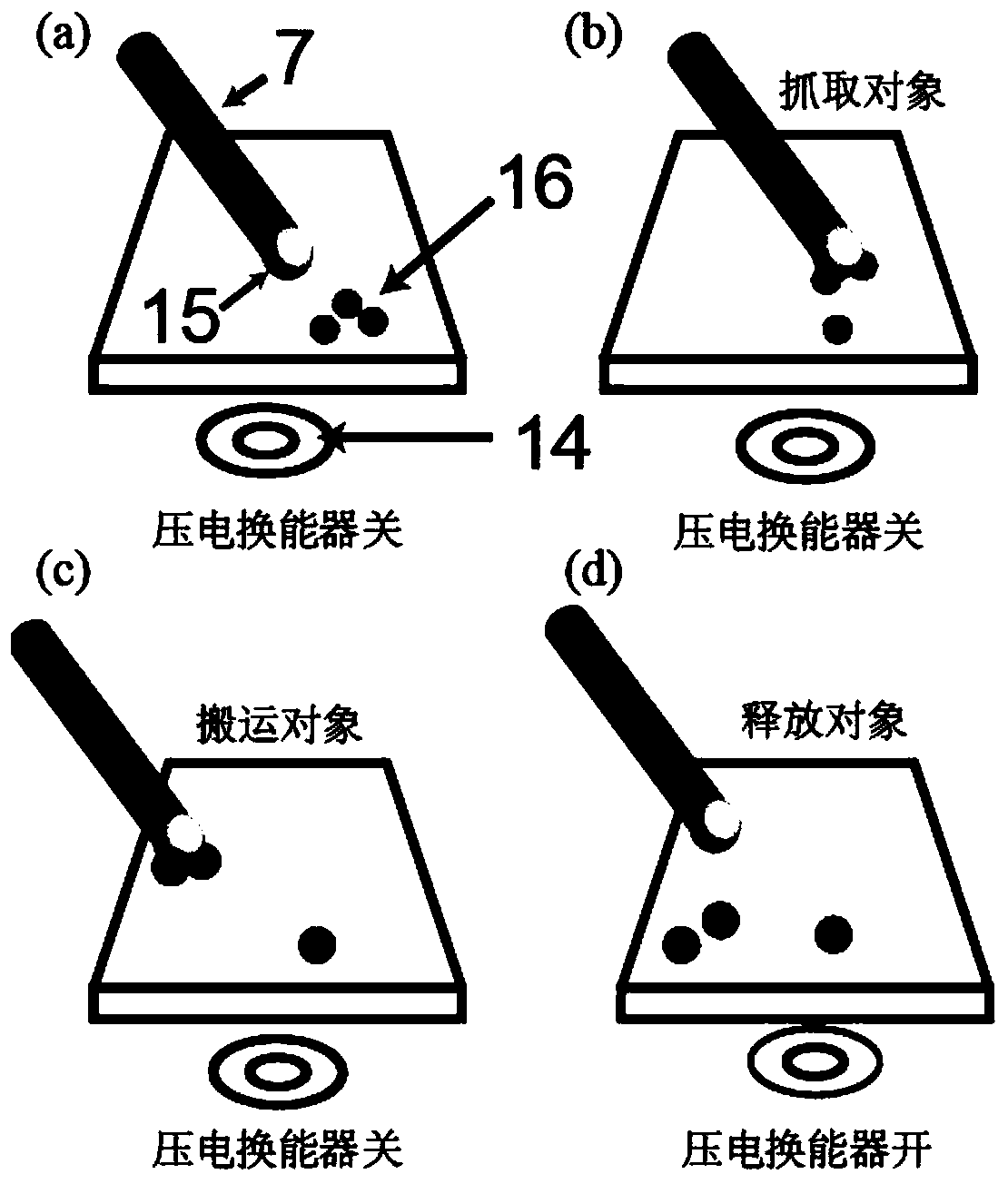

[0055] Combine below figure 1 , image 3 Description of this embodiment

[0056] A non-destructive transport method for micro-nano particles with micro-force sensing and a device for realizing the method (abbreviated as micro-nano particle transport method and device), including an optical microscope platform 1 and a No. 1 fixed connection plate fixed on the scientific microscope platform 1 2. The three-degree-of-freedom precision mobile platform 3 fixed on the No. 1 fixed connecting plate 2 . The capillary 7 for micro-nano operation is fixed on the three-degree-of-freedom precision mobile platform 3 through the second fixed connection plate 4 , and is connected with the air pressure generator and the controller 5 through the connecting pipe 6 . Both the petri dish 9 and the disc-shaped piezoelectric transducer 14 are fixedly connected to the operation base plate 10 . The operation bottom plate 10 is placed on the optical microscope platform 1 and is located below the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com