A sorting system and method for demolition construction waste

A sorting system and construction waste technology, applied in construction waste recycling, chemical instruments and methods, wet separation, etc., can solve the problems of high labor intensity, large energy waste, and many screening links, and reduce equipment downtime Failure rate, reducing the mud content of recycled aggregates, and optimizing the effect of impurity removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

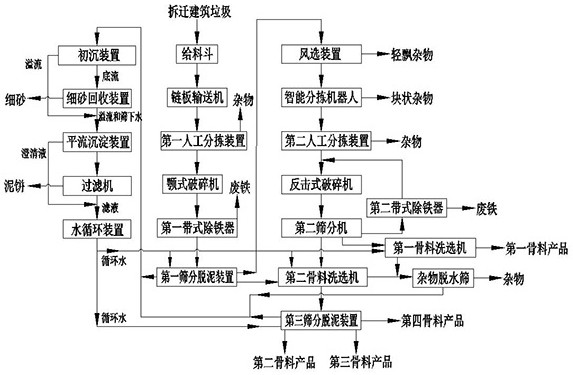

[0056] A demolition and construction waste sorting system of the present invention includes a continuous feeding system, a pretreatment system, a first screening and desliming device, a winnowing device, an intelligent impurity removal system, an impact crusher, a second screening device, Recycled aggregate washing system, third screening and desliming device, primary sedimentation device, fine sand recovery device, advection sedimentation device, filter, water circulation device and several belt conveyors; such as figure 1 As shown, continuous feeding system, pretreatment system, first screening and desliming device, winnowing device, intelligent impurity removal system, impact crusher, second screening device, recycled aggregate washing system and third screening The separation and desliming devices are connected in sequence; among them, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com