Leg breaking and marking equipment for livestock division

A technology for scribing equipment and poultry, applied in applications, slaughtering accessories, conveyors, etc., can solve the problems of high price, low efficiency and high labor intensity, save labor, avoid ineffective boosting, and improve the effect of guiding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

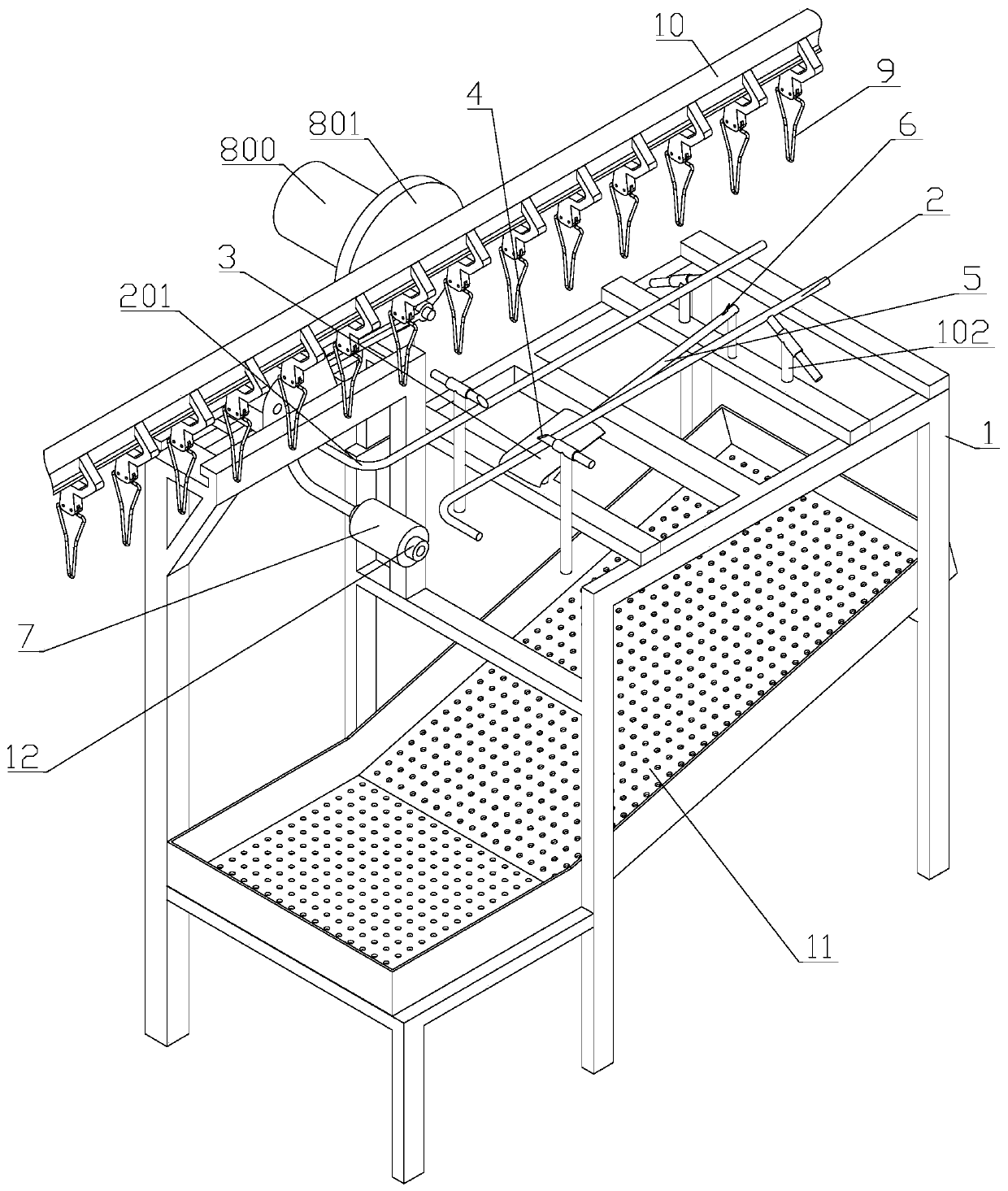

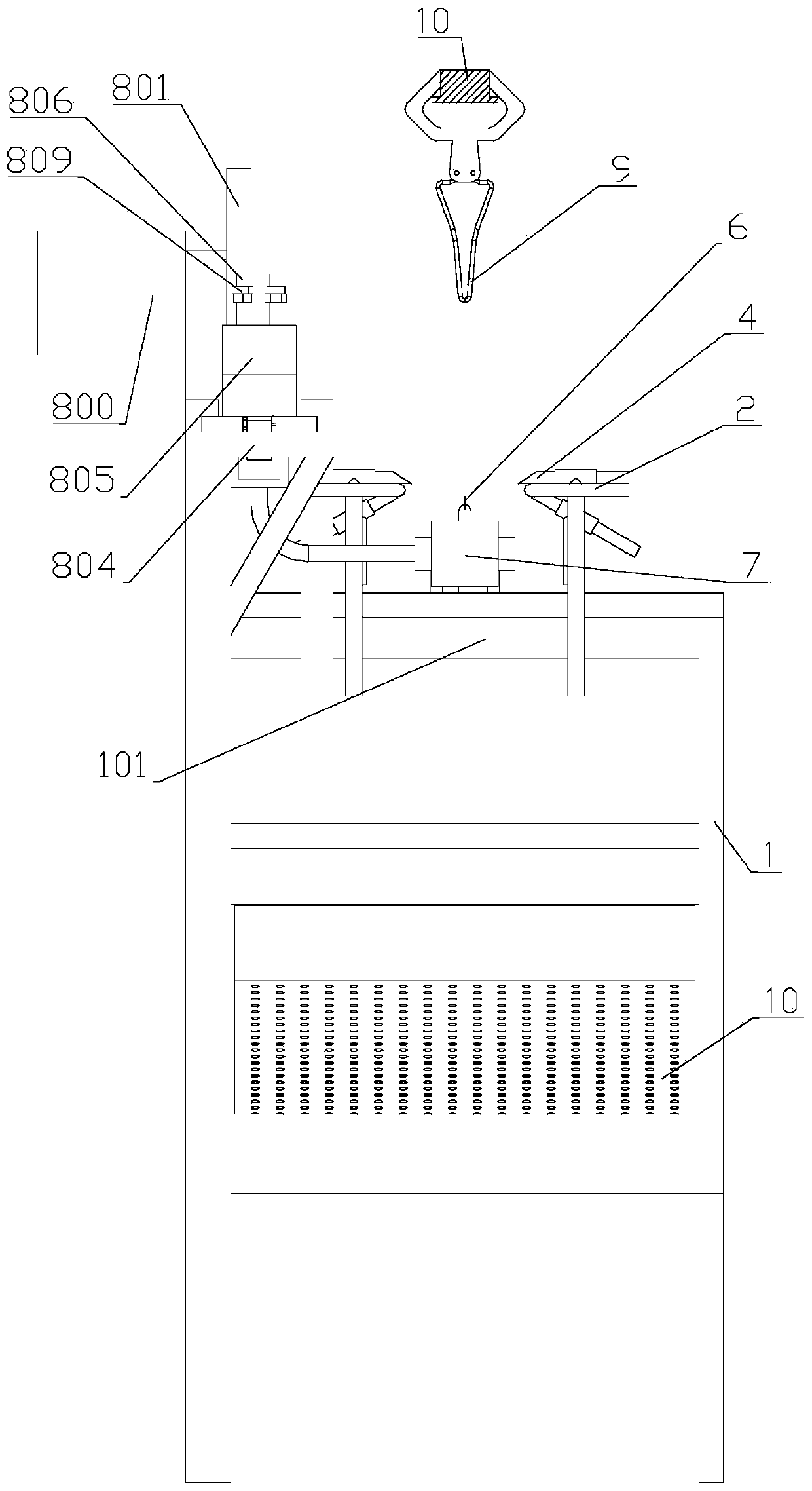

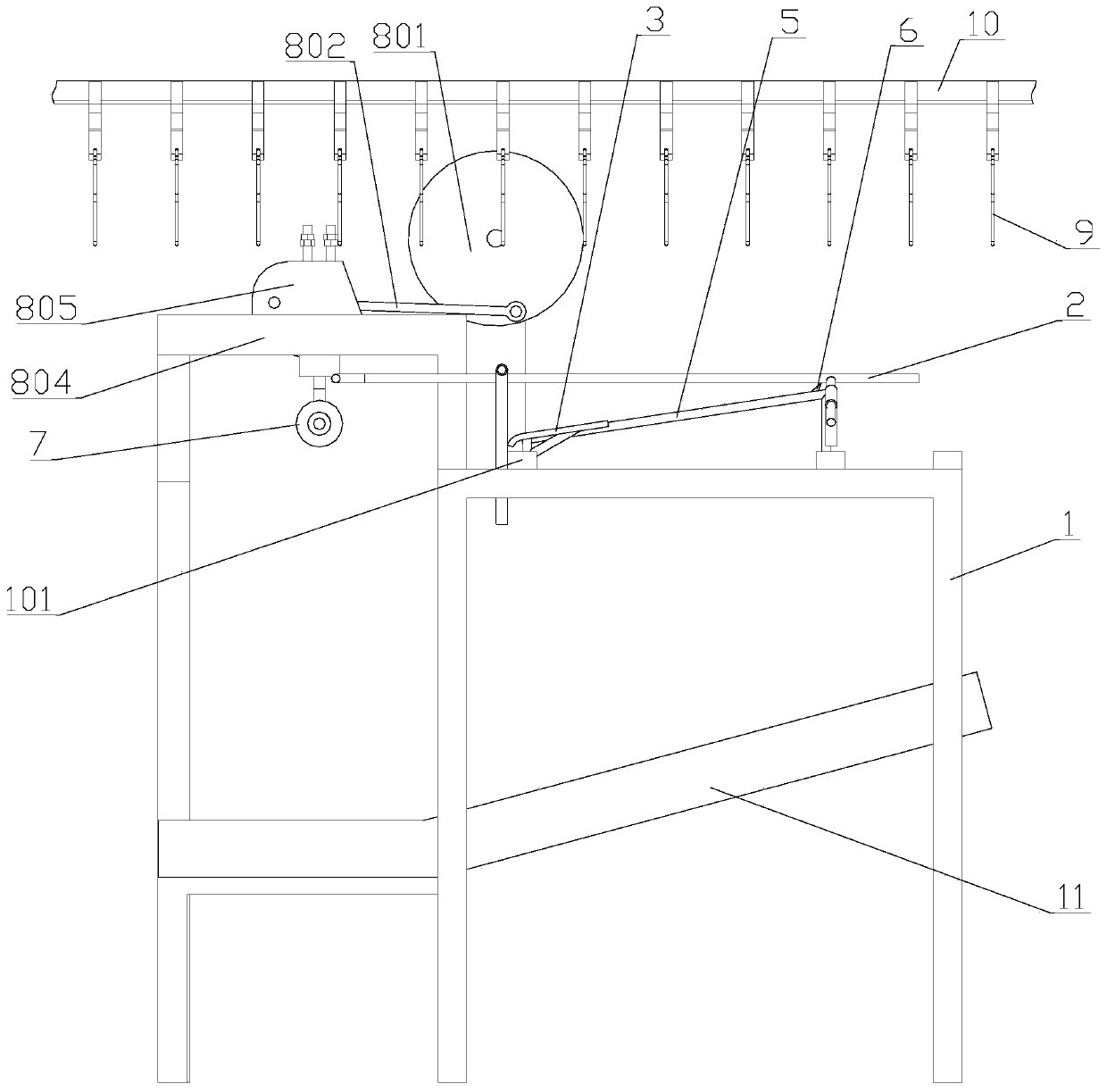

[0053] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0054] see Figure 1 to Figure 10 , the embodiment of the present invention provides a kind of leg breaking equipment for poultry segmentation, which includes a conveyor belt 10, along the conveying direction of the conveyor belt 10, a number of hooks 9 evenly arranged on the conveyor belt 10, the poultry to be broken leg marking The head of the carcass is stuck in the hook, and its carcass, wings, and legs are naturally drooping. The bracket 1 arranged below the conveyor belt 10, and the leg-breaking and marking assembly that is arranged on the bracket 1 and is located directly below the conveyor belt, are to be broken. The poultry is transported to the leg-marking assembly along with the conveyor belt, and its legs enter the leg-marking assembly along with the carcass for cutting or folding operations. At the same time, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com