Electric energy transmission aluminum piece and machining process thereof

A technology of electric energy transmission and aluminum parts, applied in the direction of electrical components, circuits, insulated cables, etc., can solve problems such as displacement of aluminum conductive devices, achieve the effects of reducing cross-sectional area, increasing heat dissipation, and reducing cross-sectional area of conductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

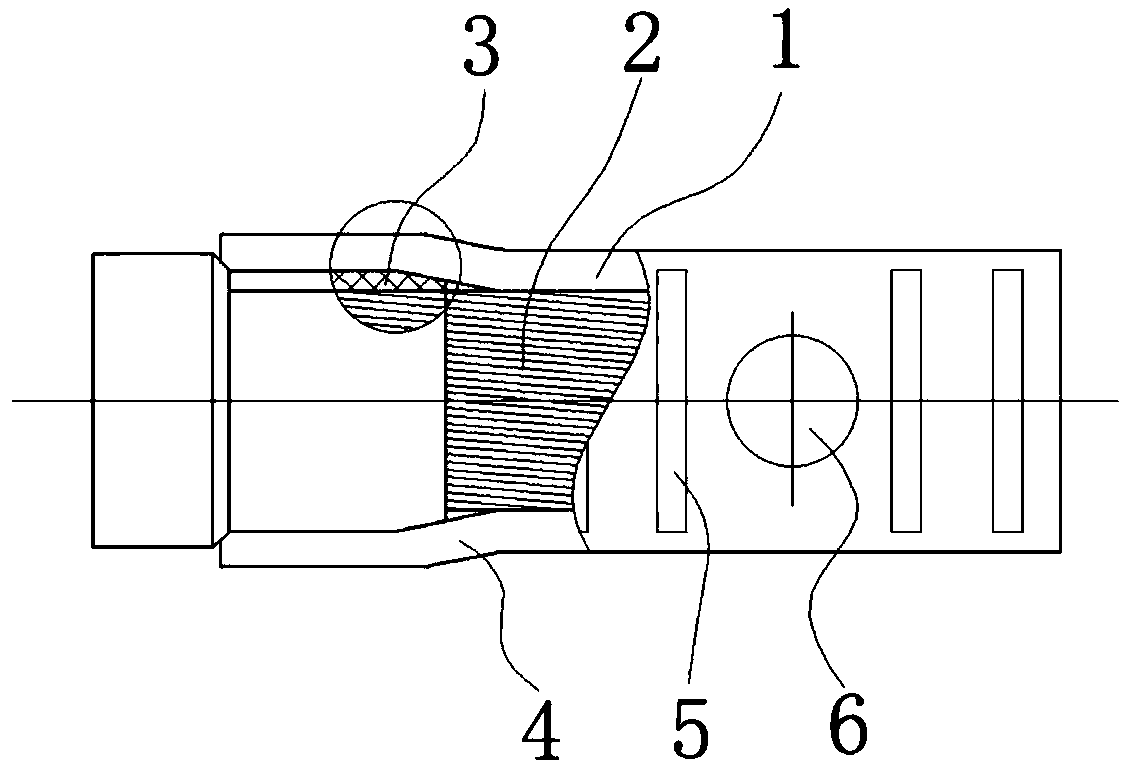

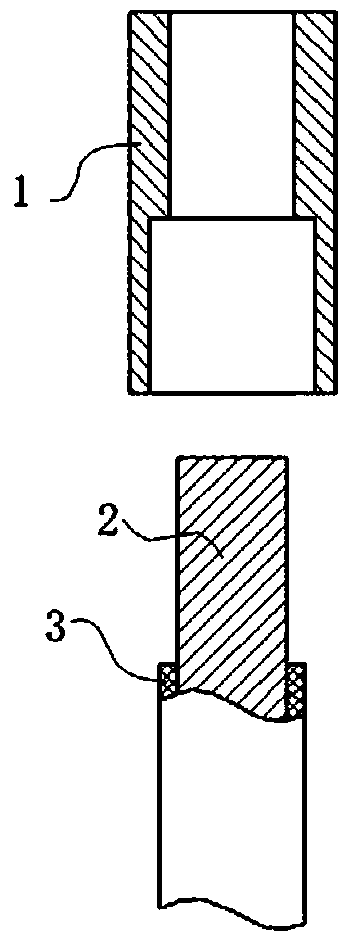

[0038] Such as figure 1As shown, an aluminum component for power transmission includes an aluminum conductive device 1 and an aluminum cable, the aluminum cable includes an aluminum conductor core 2 and an insulating layer 3 coated on the surface of the aluminum conductor core 2, the aluminum cable A section of bare aluminum conductor core 2 stripped of the insulation layer and at least part of the aluminum conductor core 2 with insulation layer 3 are crimped in the aluminum conductive device 1; inside the aluminum conductive device 1, the insulation layer and the exposed The junction of the aluminum guide core is provided with a transition section 4 with a trapezoidal axial cross-section. With the transition section 4 as the dividing point, the inner diameter of the end of the aluminum conductive device 1 crimped with the insulating layer 3 is larger than that of the aluminum conductive device 1. The inner diameter of the end of the device 1 that is crimped with the aluminum...

Embodiment 2

[0051] According to the method described in Example 1, the aluminum parts for power transmission are processed. In order to verify the influence of the ratio of the depth of the concave structure to the wall thickness of the aluminum conductive device on the pullout force and voltage drop of the aluminum parts for power transmission, the inventor investigated The pull-out force and voltage drop of the electric energy transmission aluminum parts made of different ratios of the depth of the concave structure to the wall thickness of the aluminum conductive device.

[0052] In this embodiment, the angle between the front end face of the power transmission aluminum part and the vertical plane of the axis is 0°, and the compression ratio of the aluminum core is 60%. See Table 1 for the results.

[0053] Table 1: The effect of the ratio of the depth of the concave structure to the wall thickness of the aluminum conductive device on the performance of the aluminum parts for power tran...

Embodiment 3

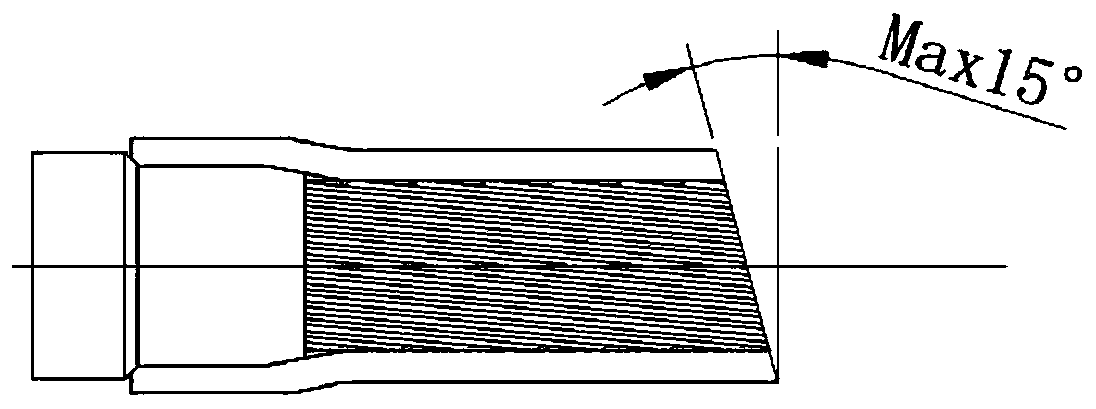

[0057] According to the method described in Example 1, the aluminum parts for power transmission are produced. In order to demonstrate the influence of the angle between the front end face of the aluminum parts for power transmission and the vertical plane of the axis on the pullout force and voltage drop of the aluminum parts for power transmission, the inventors investigated different The pull-out force and voltage drop of the power transmission aluminum parts are the angle between the front end face of the power transmission aluminum part and the vertical plane of the axis.

[0058] In this embodiment, the depth of the concave structure accounts for 50% of the wall thickness of the aluminum conductive device, and the compression rate of the aluminum core is 60%. See Table 2 for the results.

[0059] Table 2: The influence of the angle between the front face of the power transmission aluminum part and the vertical plane of the axis on the performance of the power transmission...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com