Riveting tooling for sub-beam of heliostat

A technology for riveting tooling and heliostats, which is applied in installation, instruments, lighting and heating equipment, etc., can solve the problems of easy assembly errors, labor and time, and achieve the effects of reducing labor intensity, saving materials, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A sub-beam riveting tool for heliostats proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims.

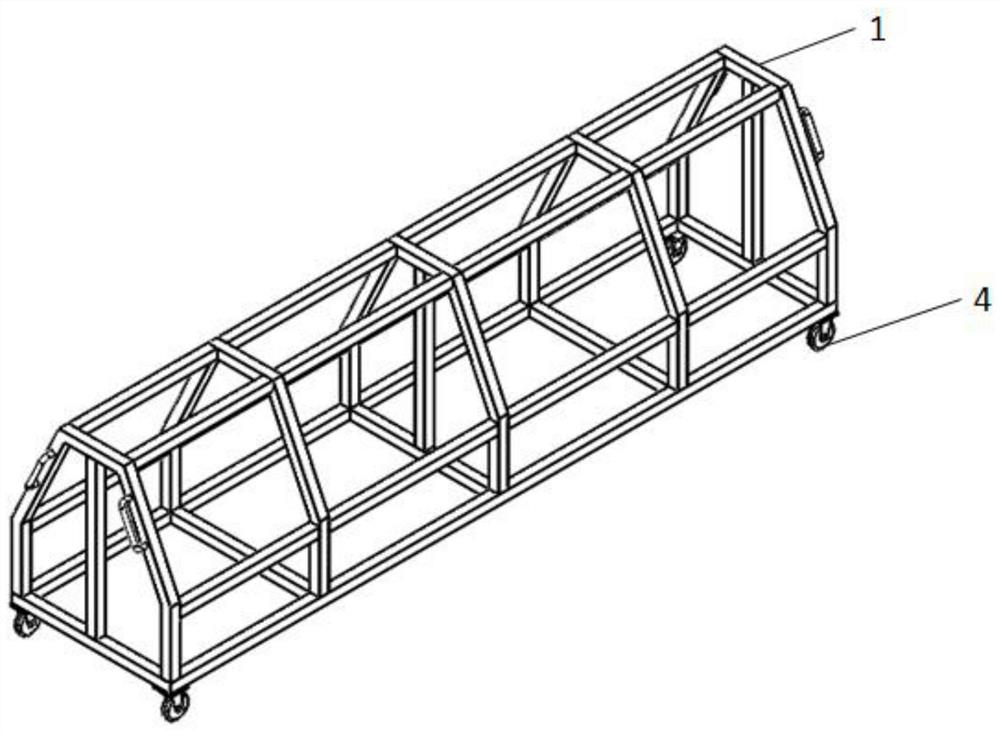

[0038] see Figure 1 to Figure 8 As shown, the present invention provides a sub-beam riveting tooling for a heliostat, including a base 1 and at least one set of sub-beam riveting units 2, see image 3 As shown, the subframe riveting unit 2 includes a first support member 21 , two second support members 22 and several third support members 23 .

[0039] The base 1 is used to install the subframe riveting unit 2, such as figure 2 As shown, in this embodiment, the base 1 adopts a truss structure, which includes a lower chassis and an upper support structure. The side waist surfaces of the waist platform are evenly arranged in a stepped form from top to bottom, which can comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com