Soil supporting device with telescopic grouting filling type shield segments and construction method

A shield segment and filling technology, which is applied in earth-moving drilling, vertical well equipment, wellbore lining, etc., can solve the problems of reducing the cement strength of segment walls, affecting the impermeability of side walls, and existing safety, etc., and achieves a wide range of applications. Market and development value, solution to delays, effect of job security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below the present invention is further described:

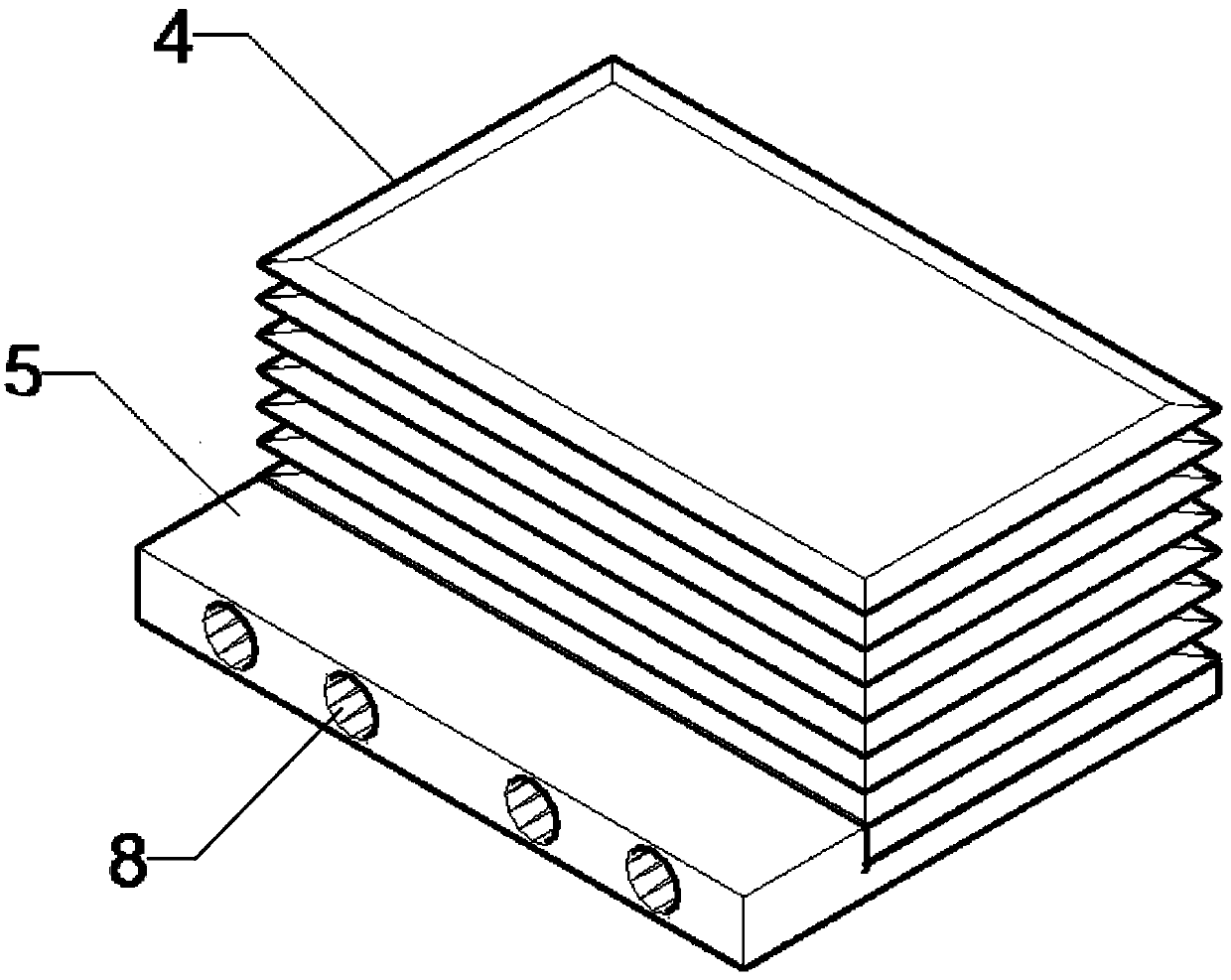

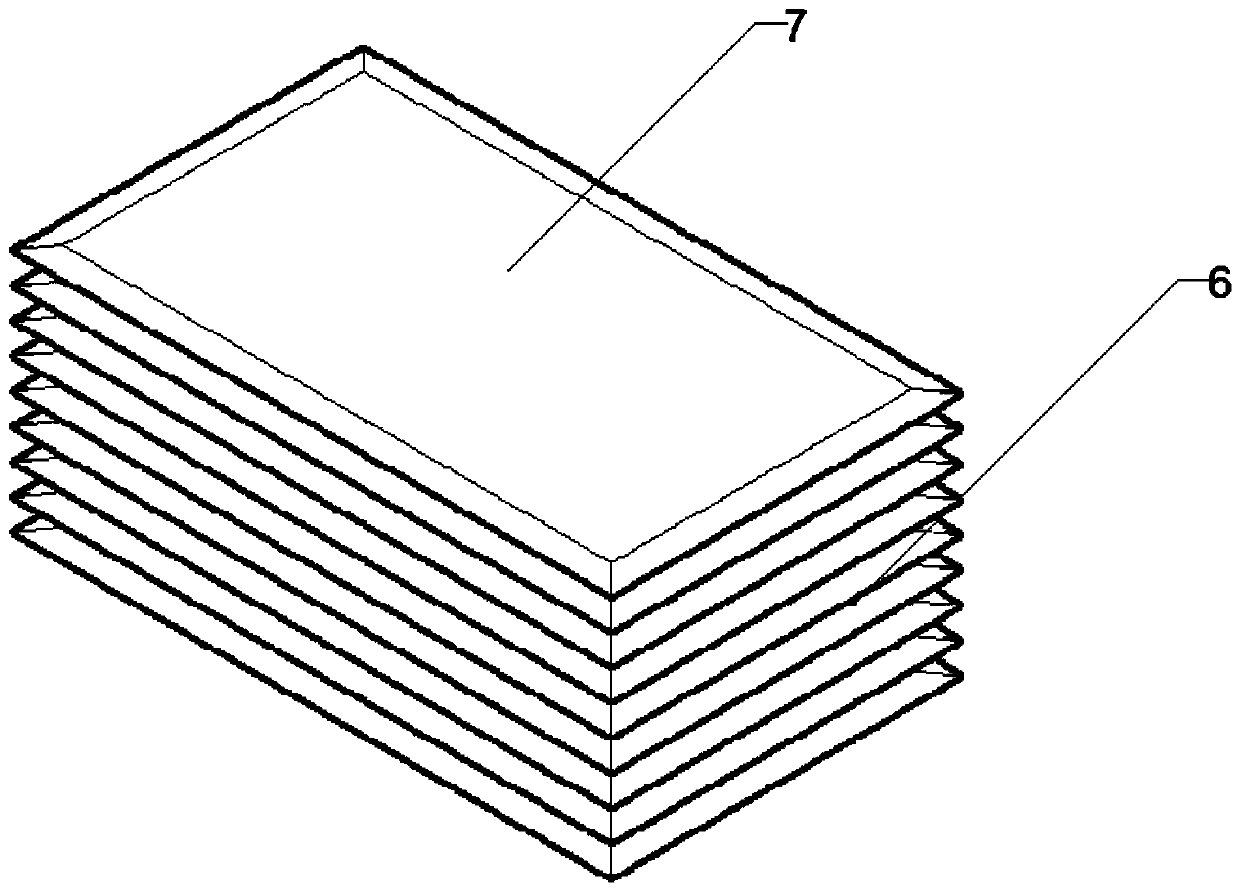

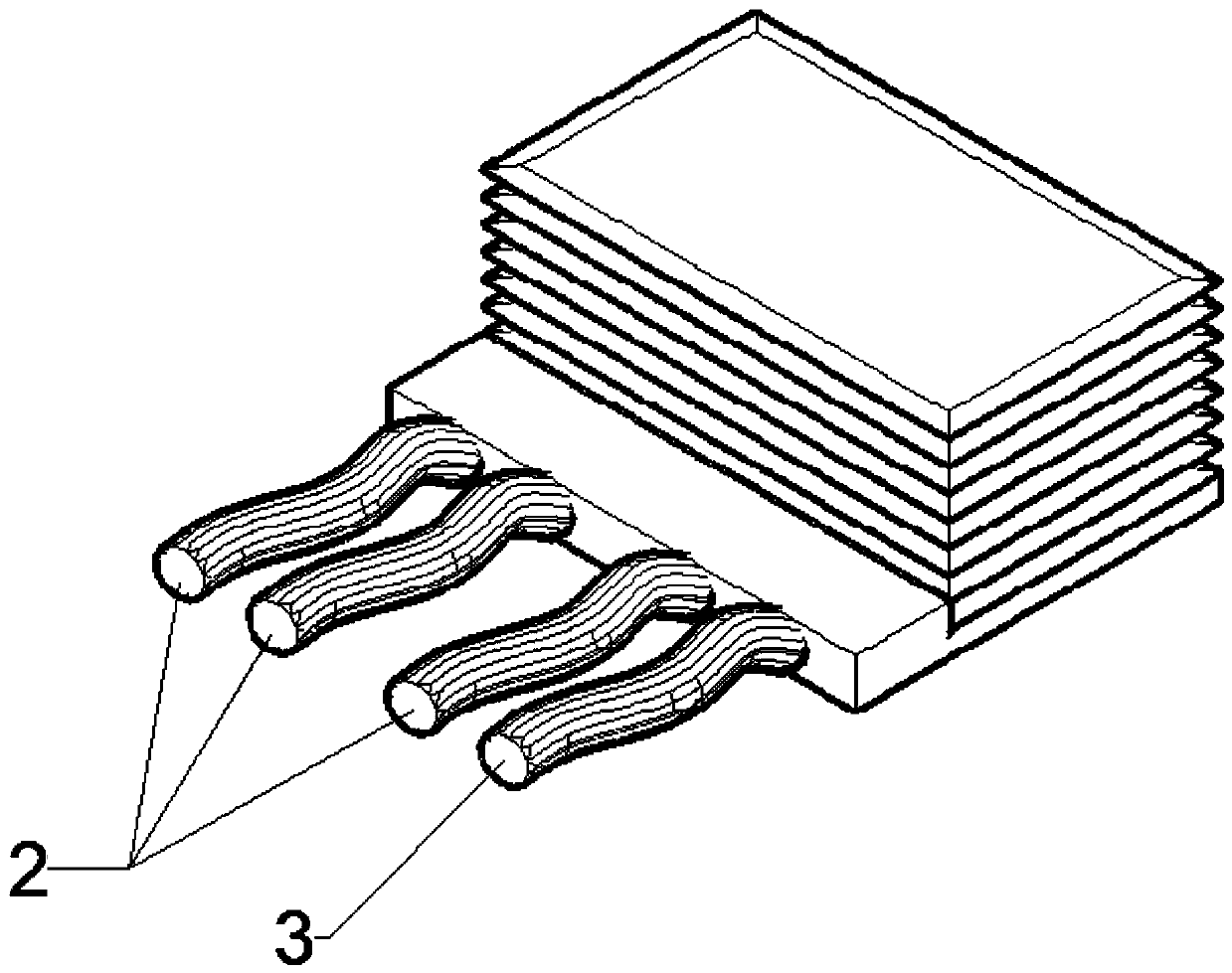

[0028] see Figure 1-4 ,

[0029] The invention discloses a shield segment soil supporting device with telescopic grouting and filling, which comprises a soil supporting device body 1, a grouting pipe 2 and a grouting pipe 3, and the soil supporting device body 1 includes a telescopic bag 4 and A fixed base 5, the flexible bag 4 is a square structure with a hollow bottom opening surrounded by a top cover 7 and a telescopic side wall 6; The connection port 8 connected with the grouting pipe 2 and the grouting pipe 3; the bottom of the telescopic bag 4 is fixed on the upper surface rear end of the fixed base 5, and the inner cavity of the telescopic bag 4 is connected with the The connection port 8 is connected, and after the mortar is injected into the telescoping capsule 4, the telescoping capsule 4 is jacked up to be in close contact with the loose soil, and a certain compressive stress is applied to effectively pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com