Heat-preservation heat-dissipation light-transmitting tempered glass plate capable of regulating and controlling functional gas pressure in glass spacing interlayer

A glass plate and tempering technology, applied in glass forming, glass manufacturing equipment, parallel glass structure, etc., can solve the problems of high yield and low cost, and achieve the effect of high yield, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

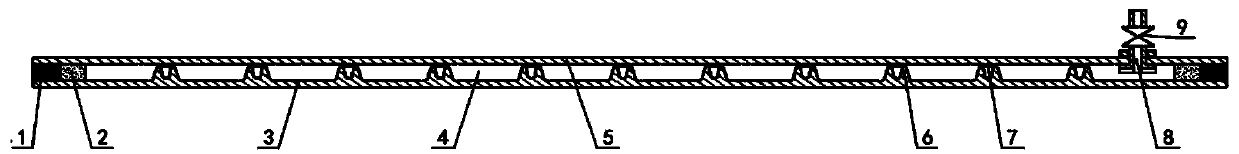

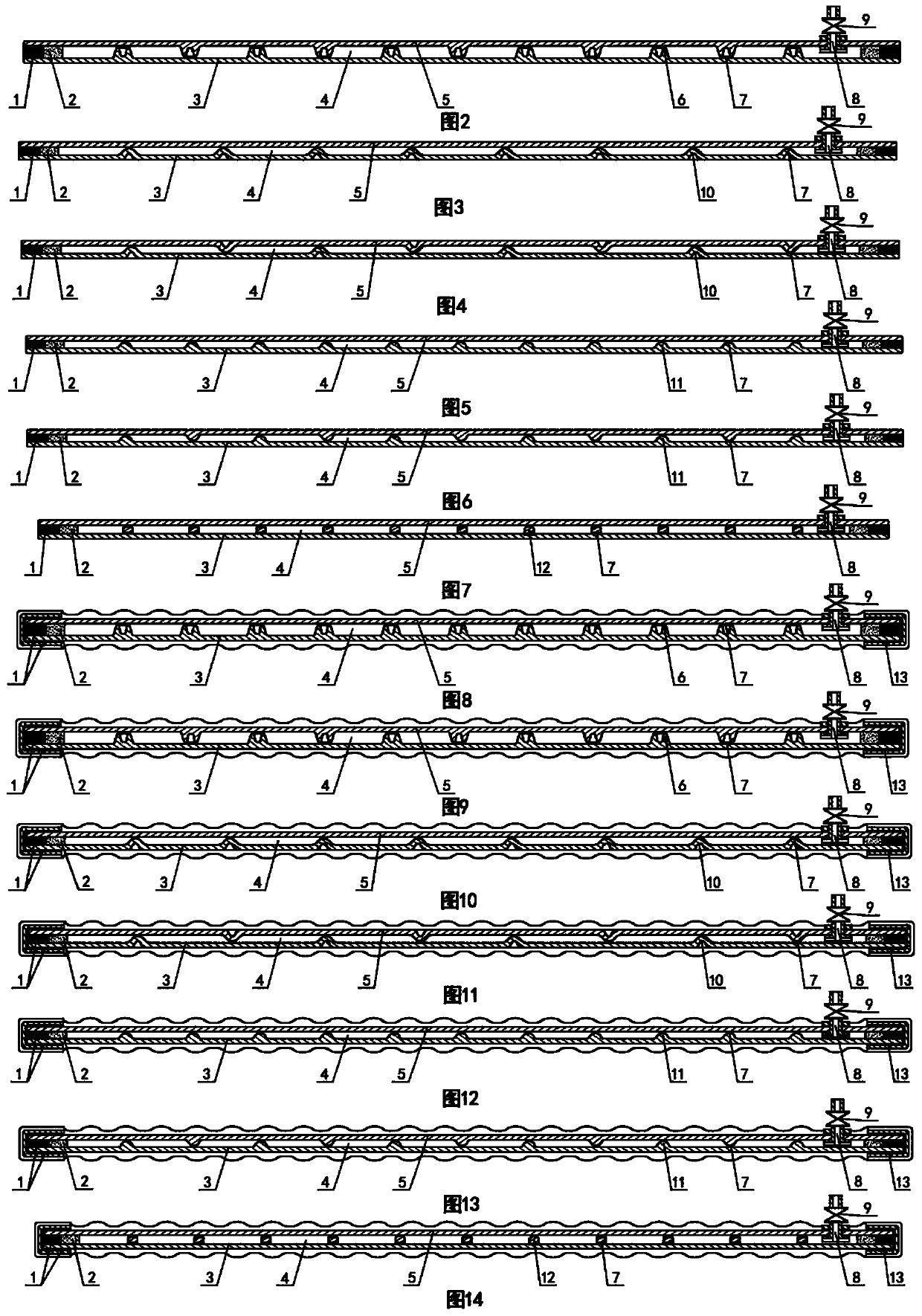

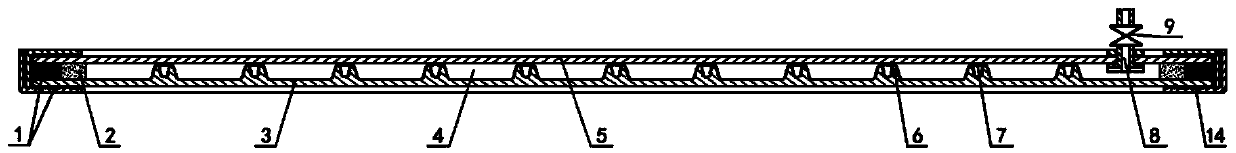

[0197] Such as figure 1 As shown: the upper tempered glass 5 and the lower tempered glass 3 with dot matrix embossing support bumps 6 correspond to each other in outline shape and size, and are complementarily fastened together, and the interval forms a hollow interlayer 4. The structure sealant 1 and the airtight sealant 2 are bonded to form a vacuum adjustable tempered glass plate. An intake and exhaust pipe 8 is installed on the vacuum tempered glass plate, and a vacuum valve 9 is arranged on the intake and exhaust pipe 8.

[0198] Such as figure 2 Shown: on the upper side tempered glass 5 and the lower side tempered glass 3, there are dots of embossed support bumps 6, the others are equivalent to figure 1 .

[0199] Such as image 3 Shown: on the lower side tempered glass 3 there are dots of stretch support bumps 10, the others are equivalent to figure 1 . Shown in 4: The upper tempered glass 5 and the lower tempered glass 3 are distributed with dots of tensile support bumps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com