A kind of manufacturing process with metallic color glossy film

A technology of metal color and production process, applied in the direction of metal layered products, decorative arts, household appliances, etc., to reduce dust deposition, improve reflection effect, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

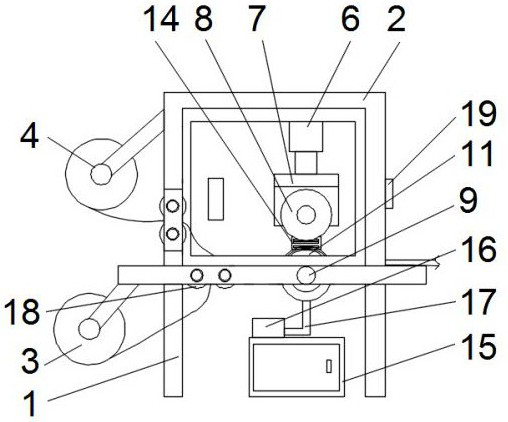

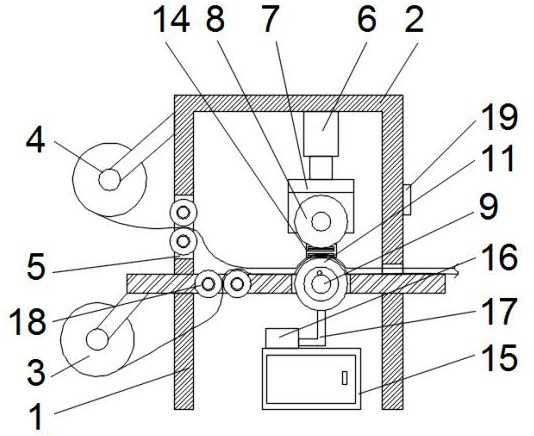

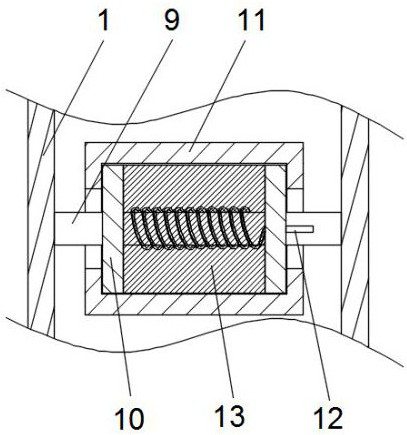

[0039] see Figure 1-2 As shown, the manufacturing process with a metallic color glossy film provided in this embodiment includes a workbench 1 on which a closed manufacturing cabinet 2 is provided, and a PET film roll 3 is provided on the workbench 1 , the production cabinet 2 is provided with an aluminum foil roller 4, and the right end of the production cabinet 2 is provided with a discharge port, and the PET film and aluminum foil protrude along the discharge port, and are arranged on the outside of the discharge port with the driving roller (Fig. not shown in ), and the PET film and aluminum foil are driven to move at a preset speed by the driving roller arranged at the right end. Both the workbench 1 and the production cabinet 2 are provided with a feed inlet 5, the production cabinet 2 is provided with a hot pressing mechanism, and the production cabinet 2 is provided with a dust suction mechanism, through the workbench 1. Make the cabinet body 2. The hot pressing mech...

Embodiment 2

[0070] see Figure 5 , this embodiment provides a technical solution: the suction head 14 is provided with several circular suction openings. Compared with Embodiment 1, another structure of the dust suction port is provided, and the dust enters the dust suction pipe 17 along the circular dust suction port to realize fast dust suction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com