A kind of wormwood modified fiber fabric

A technology for modifying fibers and wormwood, applied in the field of fiber textiles, can solve the problems of cotton fibers and polyester fibers, which are easy to breed bacteria and hygroscopic, and achieve the effects of improving hygroscopicity, meeting health benefits, and meeting the needs of wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

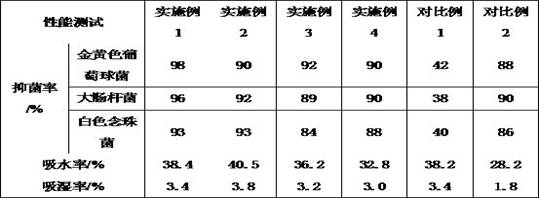

Examples

Embodiment 1

[0019] (1) Preparation method of cotton fiber modified with wormwood antibacterial factor

[0020] Steps: 1) Extraction of wormwood antibacterial factors: crush the wormwood fiber, soak it in 2% sodium hydroxide solution for 1 hour, then heat up to 80°C and cook with alkali for 2 hours, the solid-liquid solution of the wormwood fiber and sodium hydroxide solution The ratio is 100g / 1L; 2) Filter the wormwood fiber cooking solution with a 200-mesh sieve, and the remaining liquid part is the wormwood antibacterial factor modified solution. Add the cotton fiber into the antibacterial solution for soaking, and add penetrant, soaking time 3h, the solid-liquid ratio of cotton fiber and wormwood antibacterial solution is 100g / 100mL; 3) Take out the soaked cotton fiber and dry it at 40°C , drying time 8h, that is, the modified cotton fiber of wormwood antibacterial factor.

[0021] (2) Preparation method of superabsorbent starch modified polyester fiber

[0022] Steps: 1) Degradation...

Embodiment 2

[0026] (1) Preparation method of cotton fiber modified with wormwood antibacterial factor

[0027] Steps: 1) Extraction of wormwood antibacterial factors: crush the wormwood fiber, soak it in 2% sodium hydroxide solution for 1 hour, then heat up to 80°C and cook with alkali for 2 hours, the solid-liquid solution of the wormwood fiber and sodium hydroxide solution The ratio is 100g / 2L; 2) The wormwood fiber cooking solution is filtered through a 200-mesh sieve, and the remaining liquid part is the wormwood antibacterial factor modified solution. Add the cotton fiber to the antibacterial solution for soaking, and add penetrant, soaking time 4h, the solid-liquid ratio of cotton fiber and wormwood antibacterial solution is 100g / 200mL; 3) Take out the soaked cotton fiber, and dry it at 40°C , drying time 10h, that is, wormwood antibacterial factor modified cotton fiber.

[0028] (2) Preparation method of superabsorbent starch modified polyester fiber

[0029] Steps: 1) Degradatio...

Embodiment 3

[0033] (1) Preparation method of cotton fiber modified with wormwood antibacterial factor

[0034]Steps: 1) Extraction of wormwood antibacterial factors: crush the wormwood fiber, soak it in 2% sodium hydroxide solution for 1 hour, then heat up to 80°C and cook with alkali for 2 hours, the solid-liquid solution of the wormwood fiber and sodium hydroxide solution The ratio is 100g / 3L; 2) The wormwood fiber cooking solution is filtered through a 200-mesh sieve, and the remaining liquid part is the wormwood antibacterial factor modified solution. Add the cotton fiber to the antibacterial solution for soaking, and add penetrant, soaking time 5h, the solid-liquid ratio of cotton fiber and wormwood antibacterial solution is 100g / 300mL; 3) Take out the soaked cotton fiber and dry it at 40°C , drying time 11h, that is, wormwood antibacterial factor modified cotton fiber.

[0035] (2) Preparation method of superabsorbent starch modified polyester fiber

[0036] Steps: 1) Degradation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com