A finishing grinding machine with selected abrasives

A grinding machine and abrasive technology, applied in the direction of abrasives, metal processing equipment, grinding machines, etc., can solve the problems of reduced cutting sharpness, reduced processing quality, abnormal hardness and toughness of abrasives, etc., to achieve fast grinding efficiency, good quality, and improved smoothness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

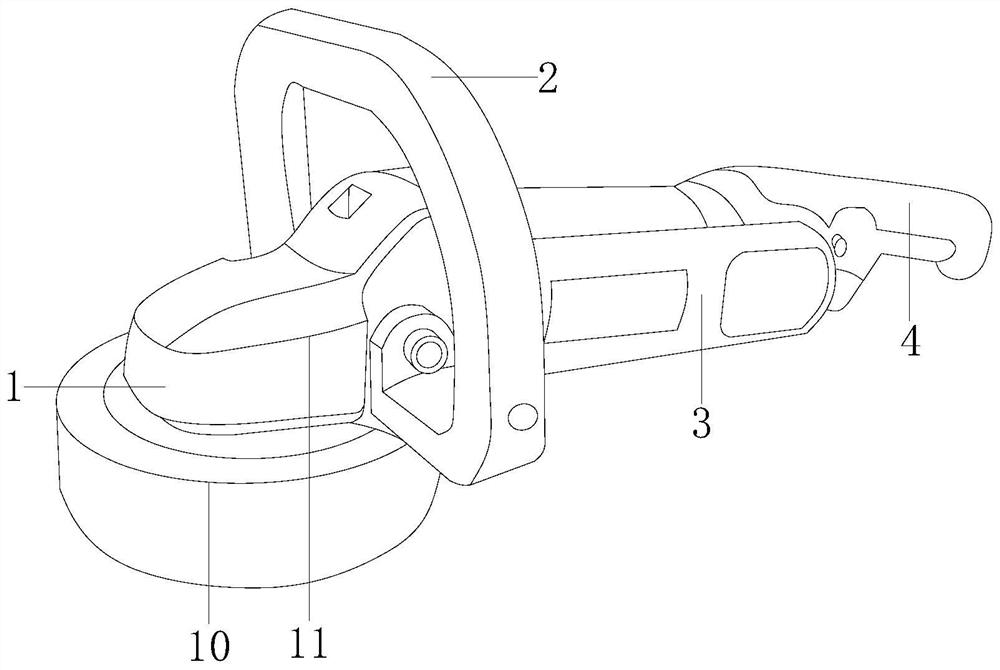

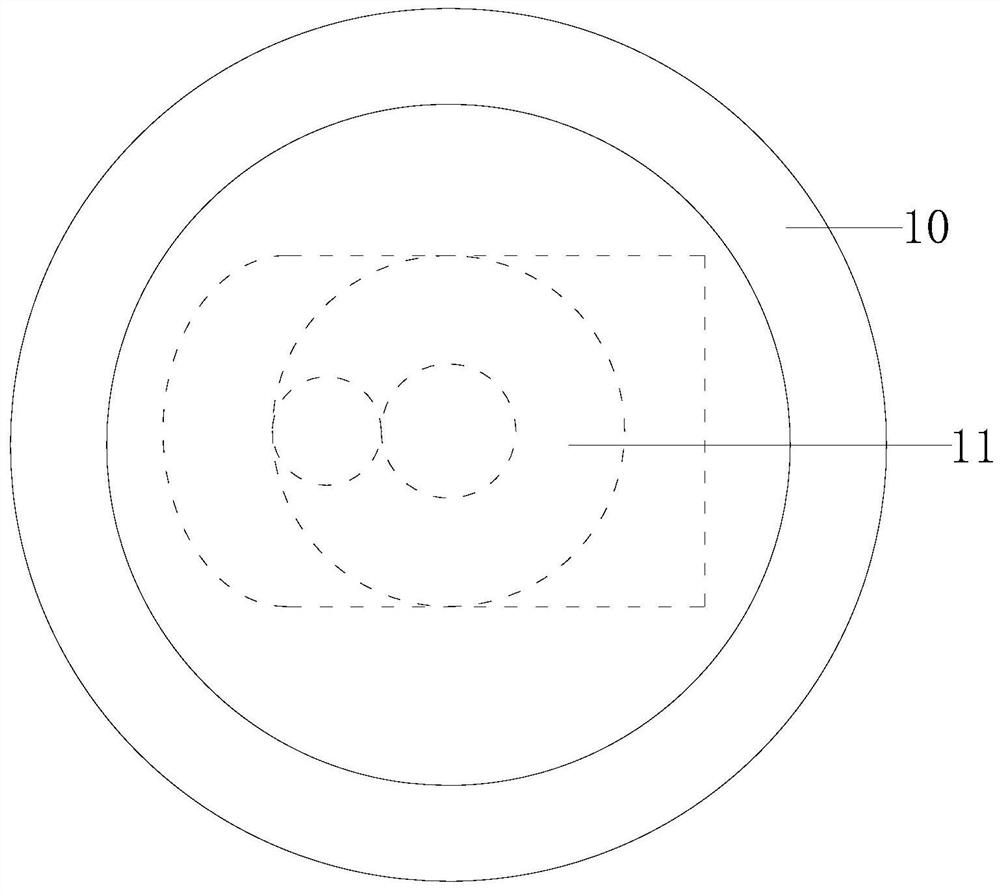

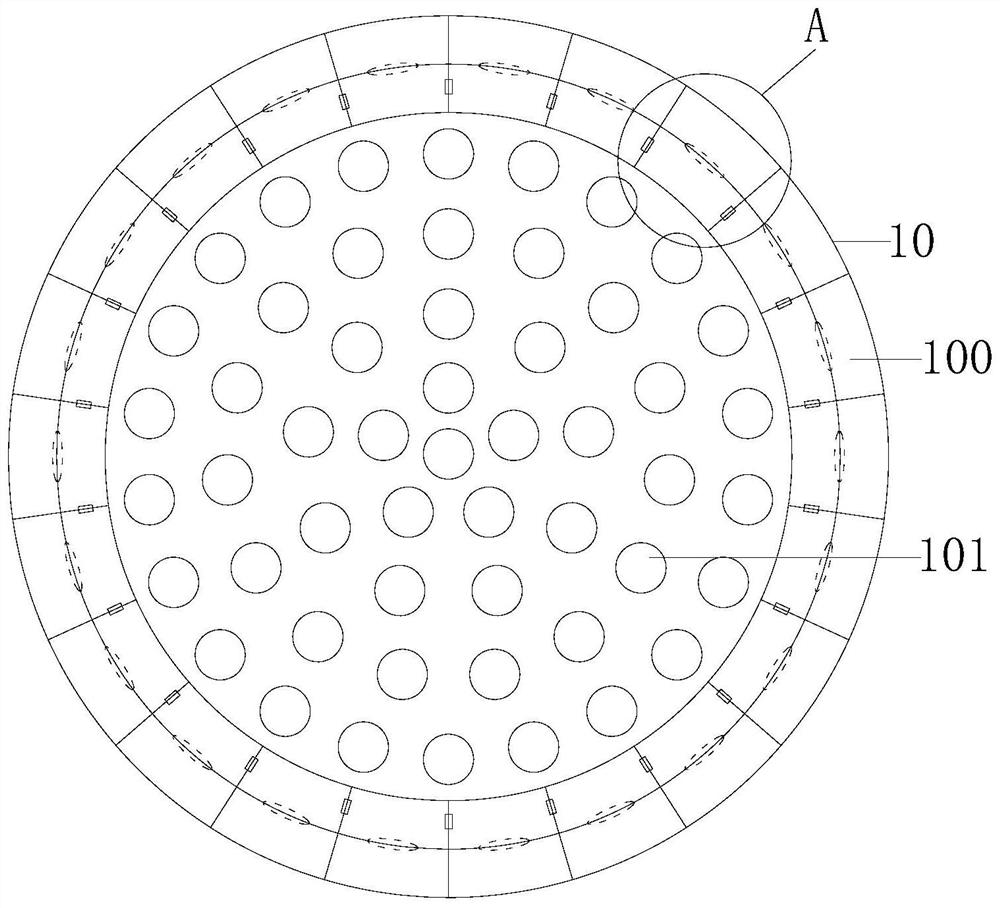

[0028] Example 1 see Figure 1-6 , the present invention provides a technical solution for finishing grinding machine with selected abrasive materials: its structure includes a machine head structure 1, a machine handle 2, a fuselage 3, and a machine tail 4, and the machine head structure 1 is installed and connected with the fuselage 3, The fuselage 3 and the tail 4 are embedded, and the head structure 1 is composed of an abrasive 10 and a head 11. The abrasive 10 is connected to the head 11. The abrasive 10 includes a grinding outer ring 100 and a grinding inner ring. Circle 101, said grinding outer ring 100 is embedded with grinding inner circle 101, said grinding outer ring 100 includes fixed grinding block 1000, transmission inner shaft 1001, movable grinding block 1002, inner circle pad 1003, said fixed grinding block 1000 An inner circle pad 1003 is embedded with the movable grinding block 1002, and the movable grinding block 1002 is equipped with a transmission inner s...

Embodiment 2

[0030] Example 2 see Figure 7-9 , the present invention provides a technical solution for a finishing grinding machine with selected abrasives: the structure of the cracked tooth collector 1011 includes a fixer 500, an inner membrane circle 501, a spring support plate 502, an outer capsule ring 503, and a collecting disc 504, The inner membrane circle 501, the spring support plate 502 are glued to the outer capsule ring 503, the fixer 500 is installed and connected to the spring support plate 502, the fixer 500 is installed and connected to the collecting disc 504, and the machine head 11 includes Cover frame 110, rotating auxiliary shaft 111, installation main shaft 112, and shaft disc 113, the cover frame 110 is locked with the shaft disc 113, the installation main shaft 112 is connected with the shaft disc 113, and the rotation auxiliary shaft 111 is connected with the installation main shaft 112 The hub 504 includes an upper cover 5040 and an arc frame 5041, the upper cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com