A new type of pole piece and tab welding process

A tab welding and pole piece technology, which is applied in the field of new pole piece tab welding technology, can solve the problems of poor consistency of the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

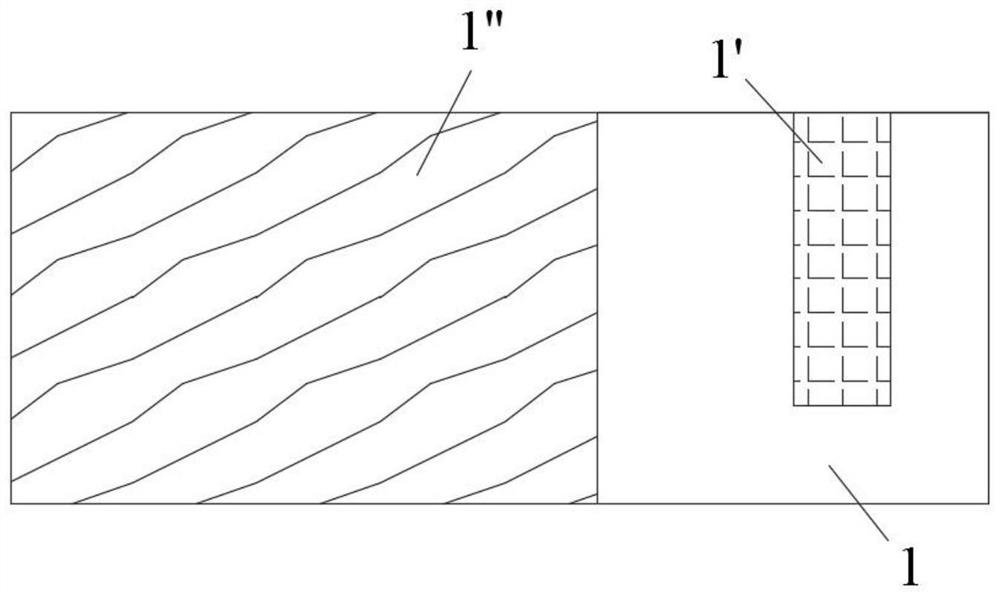

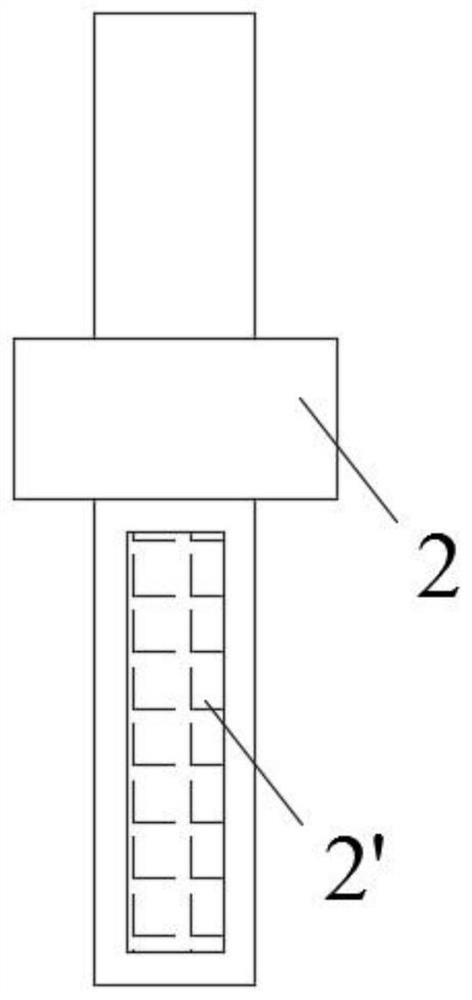

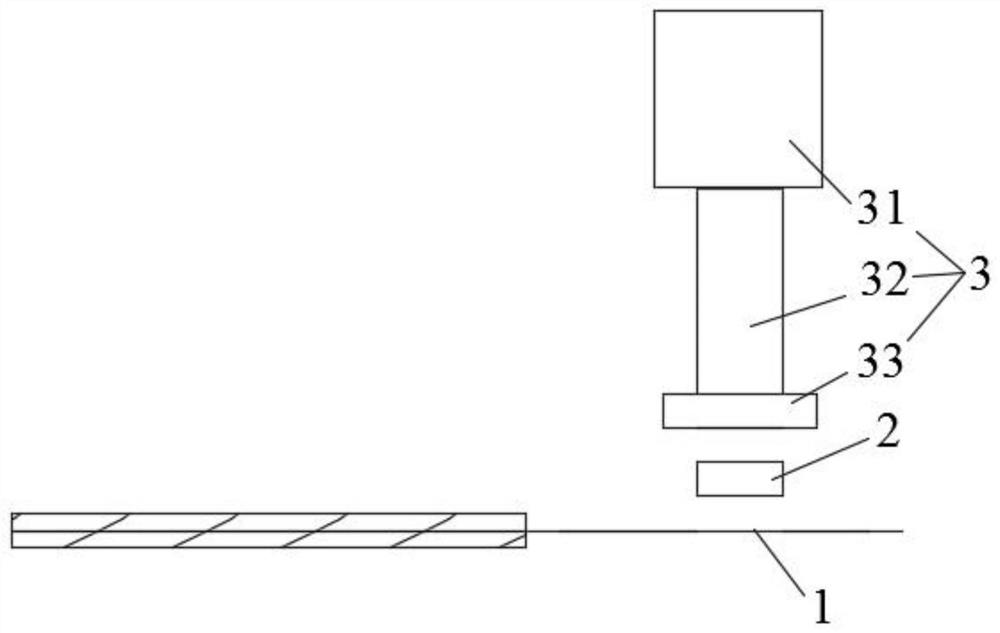

[0036] Such as Figure 1~5 As shown, a new pole piece tab welding process includes the following steps:

[0037] S1. Prepare pole piece 1 and pole lug 2 that need to be welded together;

[0038] S2, cleaning the surface of the first welding surface 1' of the metal part of the pole piece 1 and the second welding surface 2' of the metal part of the tab 2;

[0039] S3. Put the pole piece 1 and the pole lug 2 into the vacuum chamber of the vacuum cold press tooling 3;

[0040] S4. Vacuumize the vacuum chamber and keep it for a period of time; in practical applications, it is preferred to keep it for 8s to 20s;

[0041] S5. In the vacuum cavity, use the cold press tool 3 to squeeze the surface-treated first welding surface 1' and the second welding surface 2' together; in practical applications, place the pole piece 1 and the pole ear 2 on Cold-press welding is performed on the workbench of the cold-press tooling 3;

[0042] S6. Fill the vacuum cavity with dry gas to complete t...

Embodiment 2

[0054] The difference from Embodiment 1 is that in this embodiment, in step S4, the vacuum chamber is evacuated and kept for 10s. This process design makes the vacuuming effect the best, and it is beneficial to shorten the processing time.

[0055] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0057] The difference from Example 1 is that in this example, the compression ratio of cold press tooling 3 to pole piece 1 and tab 2 is 75%, and the welding pressure is 3.5 MPa. In this environment, the pole piece 1 and the pole ear 2 are closely bonded, which is conducive to the diffusion and fusion of atoms between the pole piece 1 and the pole ear 2, and the process difficulty is low, and the processing is easy to realize.

[0058] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com