A gantry submerged arc welding machine with automatic flux adjustment and drying functions

An automatic adjustment, arc welding machine technology, applied in the direction of dryers, drying, arc welding equipment, etc., can solve the problem of low flux usage rate, achieve improved flux utilization rate, good equipment operation, and reduce recycling welding The effect of the dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

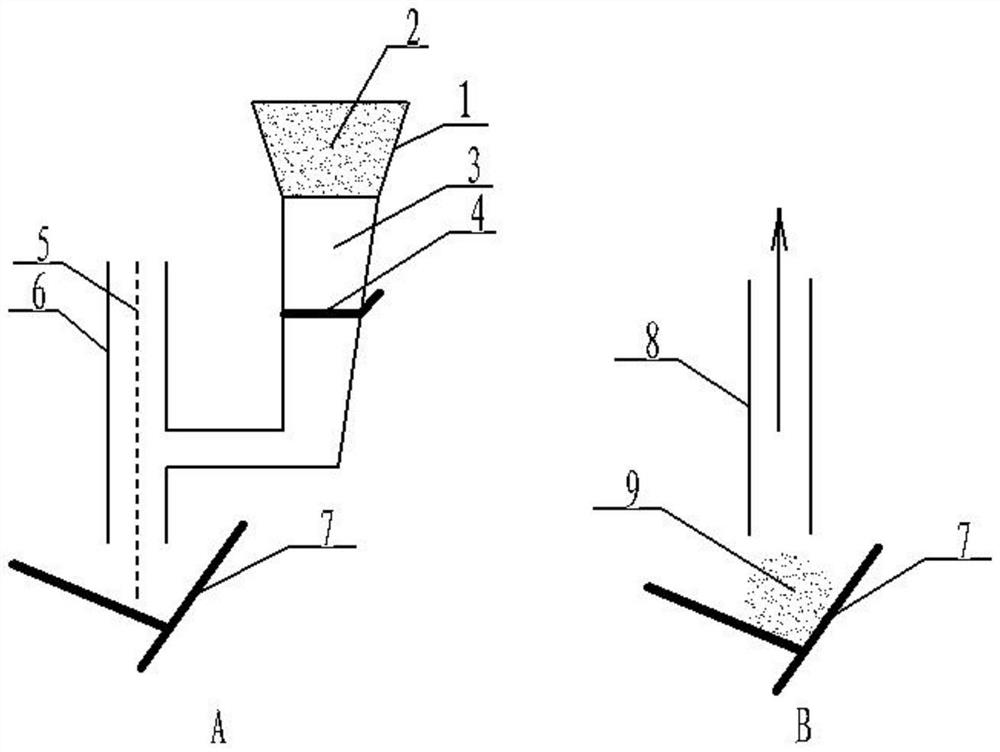

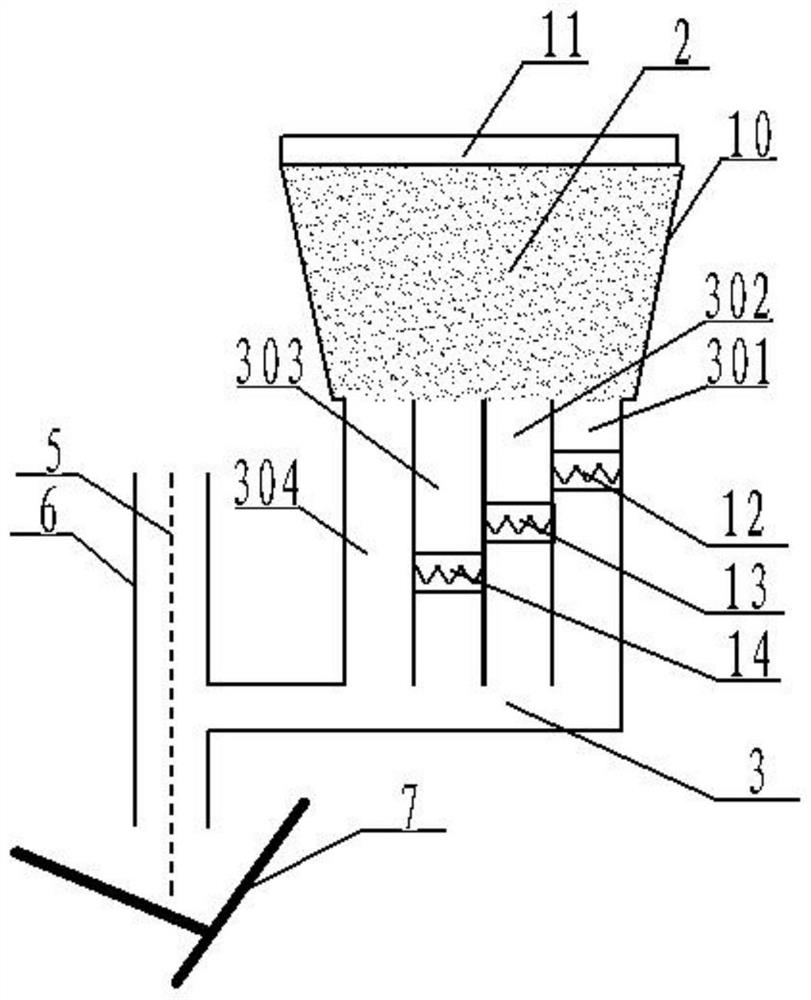

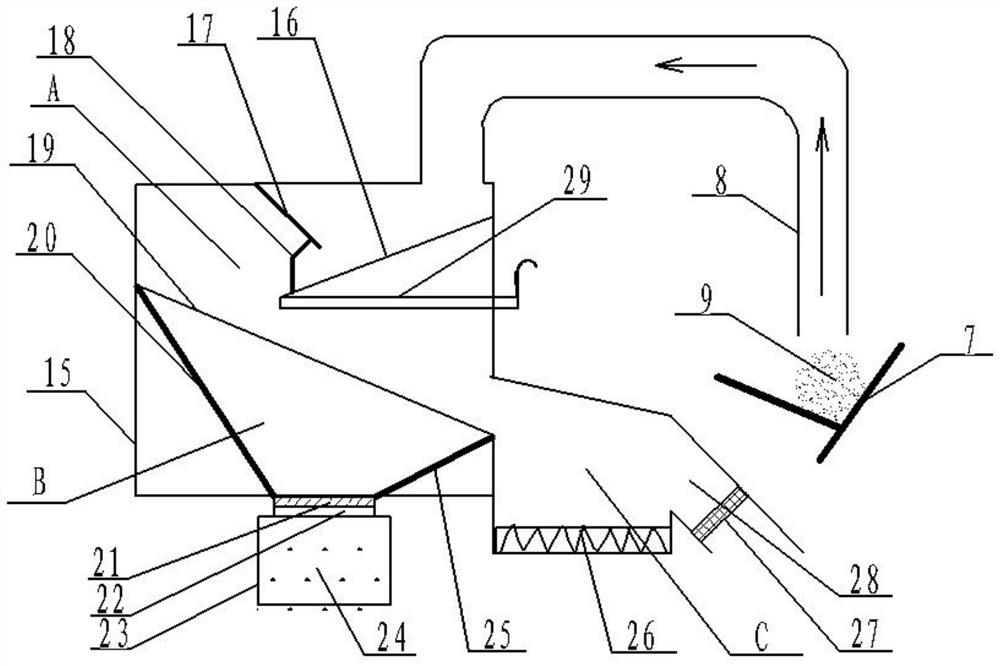

[0039] The existing gantry submerged arc welding machine mainly includes the main machine, welding cabinet, welding torch, guide rail, open trapezoidal box 1, solder 2, solder channel 3, manual control valve 4, welding wire 5, welding wire channel 6, suction pipe 8, storage box 15 and other components. Submerged arc welding is mainly used to weld workpieces with a corner seam of 30°~120°. The guide rail in the gantry submerged arc welding machine can automatically adjust the welding accuracy (the angle of the guide rail can be selected according to the welding corner seam of the workpiece), and the straight line accuracy can always be maintained. Less than 1mm, to ensure the straight line accuracy of the weld bead. However, the existing gantry submerged arc welding machine has certain problems in the process of welding flux filling and recycling, which will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com