3D printing manufacturing method of high-ventilation-capacity anti-virus and anti-smog sealing type mask

A technology of 3D printing and manufacturing method, applied in the field of sanitary protection products, can solve the problems of ineffective fit, the edge of the mask body is not tightly closed, and the wearer cannot effectively ventilate, etc., to achieve the effect of ensuring effective ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0020] A 3D printing manufacturing method of a high-ventilation anti-virus and anti-haze airtight mask of the present invention comprises the following steps:

[0021] 1) Three-dimensional scanning of the three-dimensional data of the human face;

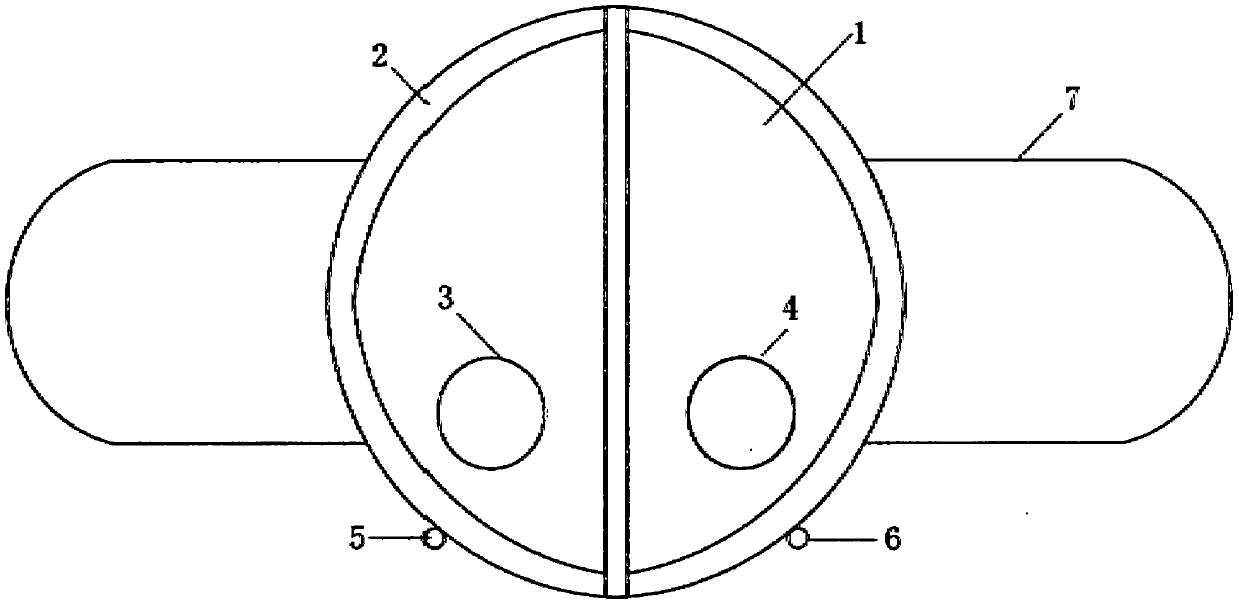

[0022] 2) Design the mask body and edge three-dimensional model of the mask with three-dimensional reverse engineering software;

[0023] 3) Use the integrated 3D printing of soft and hard or die-casting molding, in which the cover body is made of airtight hard light-weight transparent material, and the edge area is made of soft transparent material;

[0024] 4) The two sides of the mask body corresponding to the mouth and nose are respectively provided with an air intake channel and an exhaust channel;

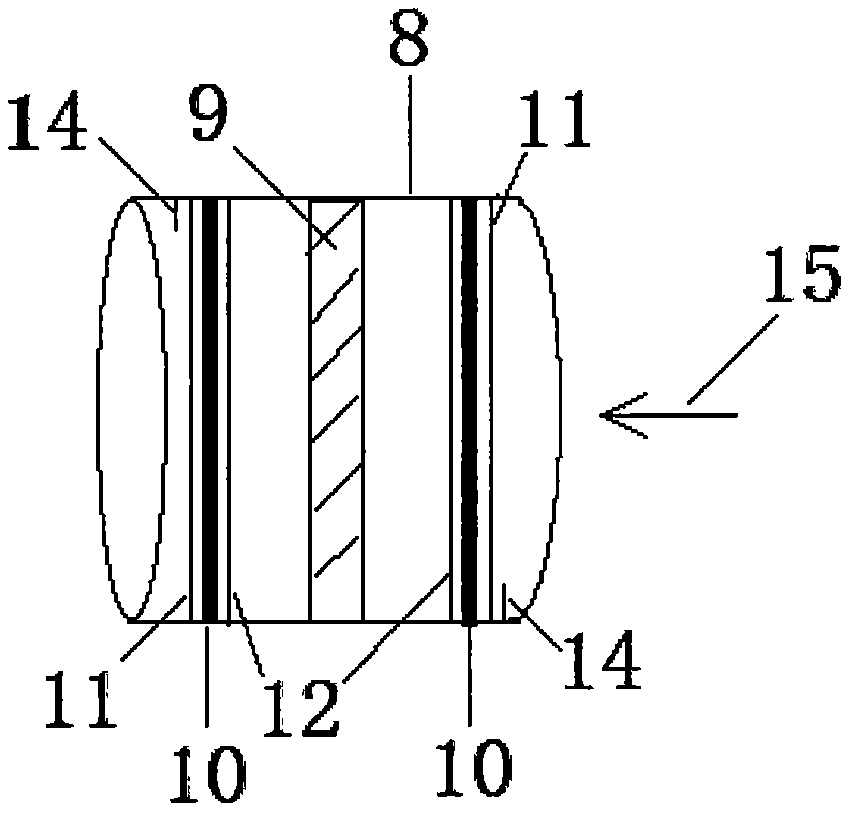

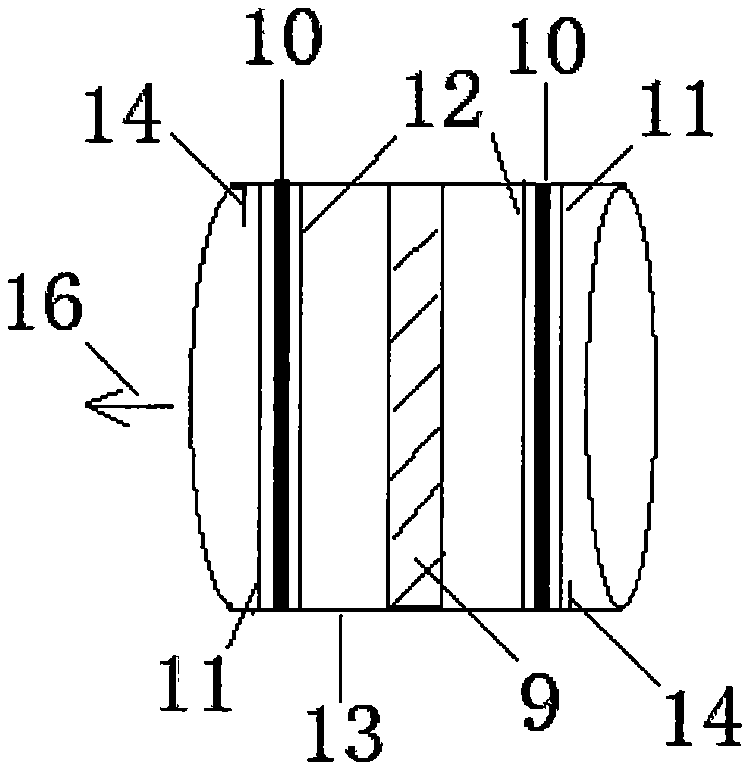

[0025] 5) There are three inner and outer layers at the inlet and exhaust channels, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com