A kind of solar battery string, battery component and preparation method thereof

A technology of solar cells and components, applied in the field of solar cells, can solve the problems of high input costs, reduce transportation and installation costs, improve space utilization, and improve power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

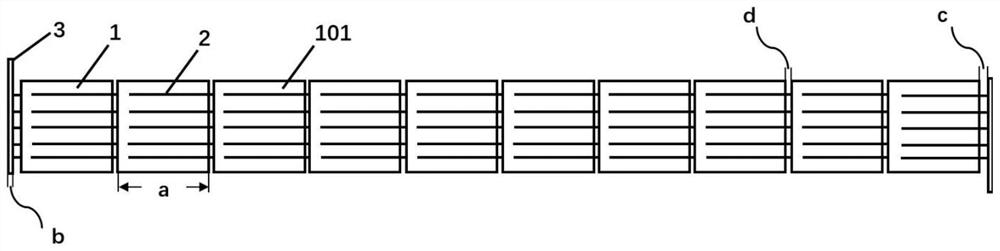

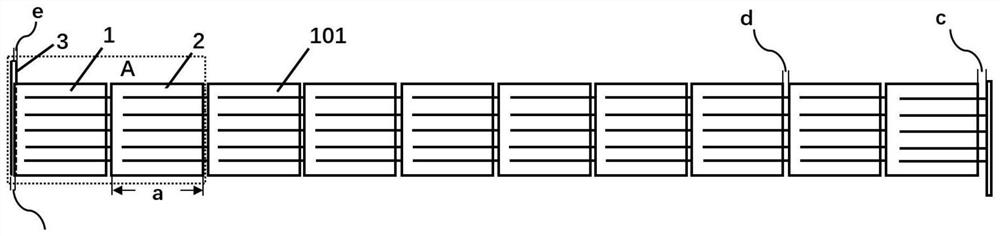

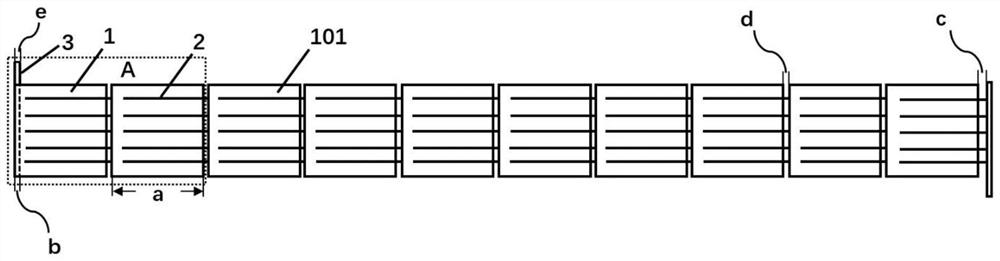

[0049] A specific embodiment of the present invention discloses a solar cell string, including a plurality of battery sheets 1, a welding ribbon 2 connecting the plurality of battery sheets, and a bus bar connected to the welding ribbon, and the bus bar includes a first segment bus bar 3 and the second busbar. A solar cell string is formed by connecting multiple solar cells with ribbons.

[0050] When the ribbon of the solar cell string is connected to the bus bar with the ribbon at the beginning or end of the backlight side, the first section of the bus bar overlaps with the solar cell string whose ribbon is at the beginning or end of the backlight Placement, the first section of bus bar is arranged along the extension direction of the solar cell string perpendicular to the solar cell string, at the edge of the solar cell string at the beginning or end of the solar cell string, such as Figure 2-5 shown. Specifically, the solder ribbon partially overlaps or fully overlaps t...

Embodiment 2

[0058] Another specific embodiment of the present invention discloses a solar cell assembly, which includes a plurality of solar cell strings, and the plurality of solar cell strings are arranged in dislocations, such as Figure 8 As shown, adjacent solar cell strings are connected by bus bars to form a solar cell module. The arrangement of conventional solar cell modules is as follows: Figure 9 shown.

[0059] Specifically, the overlapping part of the bus bar and the battery sheet is only arranged on the back of the battery sheet, and the bus bar at the other end is conventionally connected to the battery sheet. This is because: if the bus bars at both ends overlap with the cells, the front light-receiving surface will be blocked by the solder strips, which will affect the power generation of the entire photovoltaic module, such as Figure 10 and 11 shown. In this embodiment, the distance c between the battery sheet and the bus bar at the tail end or head end of the sola...

Embodiment 3

[0065] This embodiment discloses a method for preparing a solar cell module, comprising the following steps:

[0066] Step 1: Connect the battery slices into a solar battery string through soldering strips;

[0067] Step 2: Connect the solar cell string with the solder ribbon on the back of the solar cell string at the beginning or end of the battery sheet to the bus bar. When connecting, the bus bar and the battery sheet are overlapped;

[0068] Step 3: Leave a certain distance c between the solar cell string ribbon at the end of the light-receiving surface or the first end of the solar cell and the bus bar to obtain a string of solar cell strings;

[0069] Step 4: Repeat steps 1-3 to get multiple strings of solar cells;

[0070] Step 5: Place multiple strings of solar cell strings in dislocation, the length of the dislocation of adjacent solar cell strings is f, and connect them by bus bars to form a solar cell string group;

[0071] Step 6: Lay the solar cell strings on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com