Device and method for simulating heat transfer and flow law during hot oil spraying and heating in oil storage tank

A technology of heating process and simulating device, applied in measurement device, fluid dynamics test, material thermal development, etc., can solve the problem that the crude oil storage tank heating cycle heating process cannot be directly applied, and achieve rich test data and accurate control of experimental conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing, the present invention will be further described:

[0054] The invention provides an experimental device and method for studying the heat transfer and flow laws of the hot oil spraying heating process in the oil storage tank, which is suitable for testing the flow and temperature distribution of crude oil and refined oil, and is used for crude oil and refined oil in the storage tank. The coupling characteristics of heat transfer and flow in the process of hot oil spraying heating, static storage, sending and receiving oil are studied.

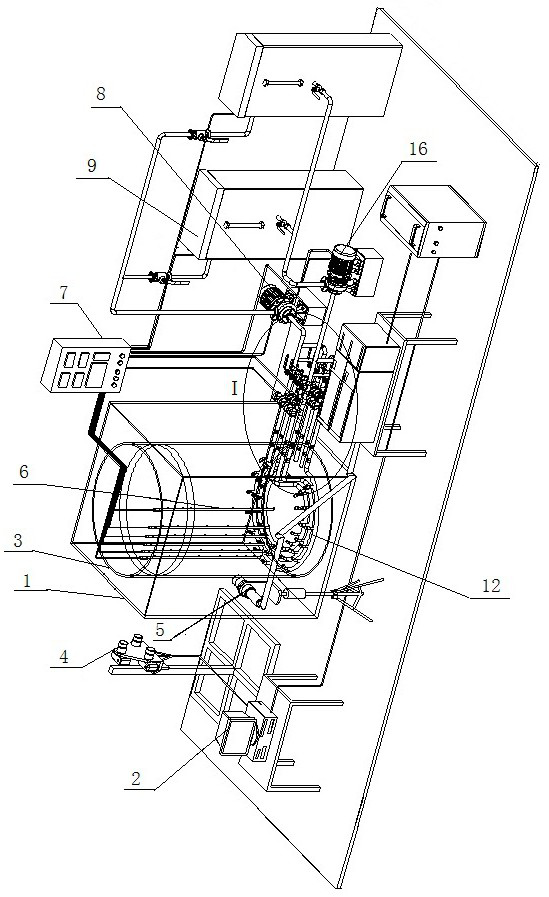

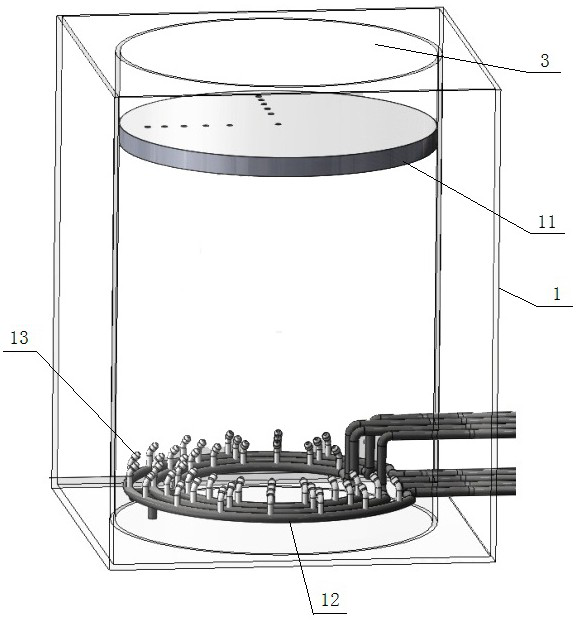

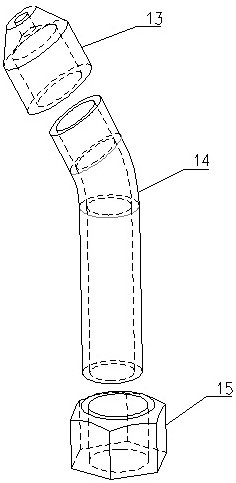

[0055] Such as figure 1 As shown, the heat transfer and flow law simulation device for the thermal oil spraying heating process of the oil storage tank includes a cylindrical experimental storage tank 3 with a movable floating roof that is in close contact with the experimental oil sample and connected with the tank wall through a sealing structure The floating roof is arranged with a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com