An evaluation method for the effect of the flow field modification of the secondary wind box of the opposing coal-fired boiler

A technology of secondary air box and evaluation method, which is applied in the testing of combustion equipment, machinery/structural components, instruments, etc., can solve the problem of insufficient stability of combustion optimization effect, and achieve the effect of enriching evaluation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

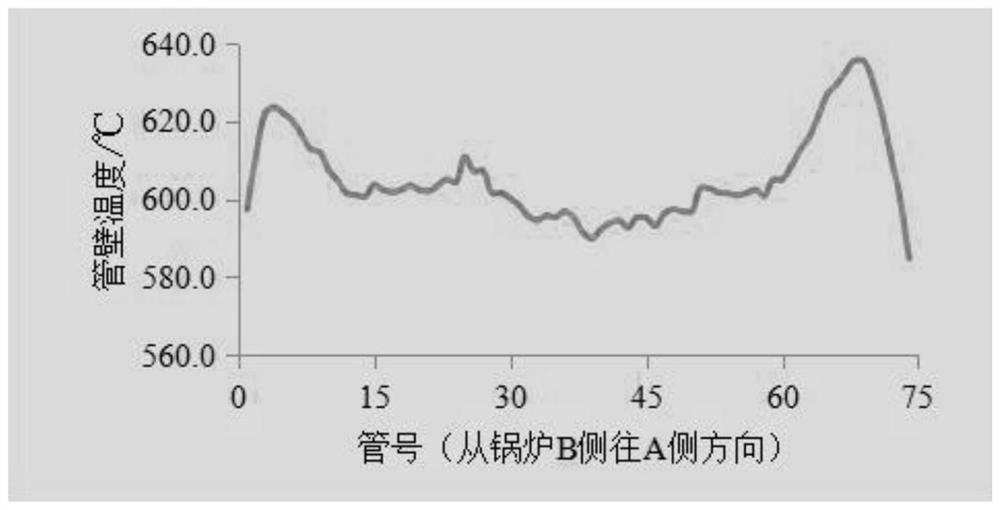

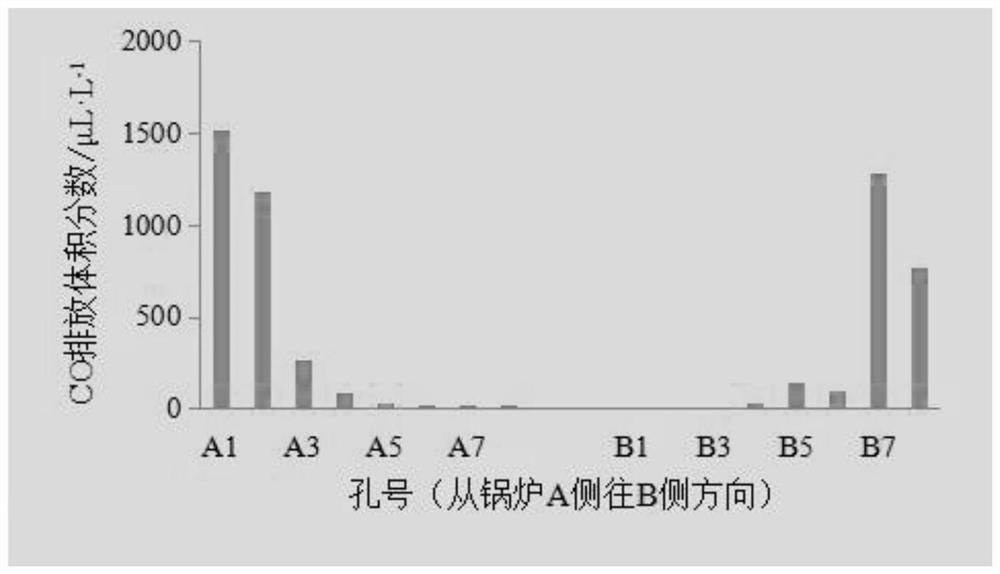

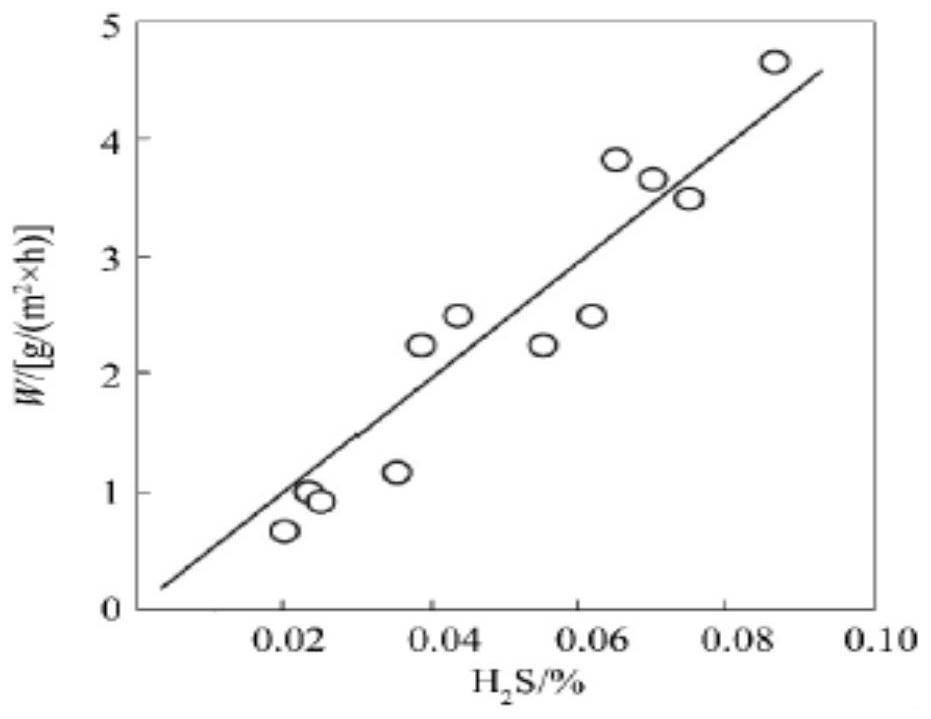

[0085] Table 1-2 shows the comparison of the data before and after the renovation of a million-million-counter-contrast coal-fired boiler after the secondary air box was retrofitted against the overheating of the tube wall and the high-temperature corrosion of the water-cooled wall.

[0086] Table 1 Statistics of measured cross-sectional wind speed under the original air duct layout:

[0087]

[0088] The numerical simulation results show that the flow field distribution of the secondary air volume measurement section on the A / B side is extremely uneven under the original air duct layout, and the relative standard deviation of the velocity distribution is 36% (the average velocity is 18.27m / s), and the section appears Obvious fast and slow separation.

[0089] Table 2. Statistics of measured section wind speed after optimization:

[0090]

[0091] The flow field optimization results show that the flow field distribution uniformity of the total secondary air volume measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com