Steel mill logistics remote intelligent metering management system through wide area network

A management system and wide area network technology, which is applied in the field of remote intelligent metering management system of steel plant logistics, can solve the problems of low efficiency of metering vehicles to be metered at several metering points, achieve high protection level, reduce work intensity, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment, further illustrate the present invention.

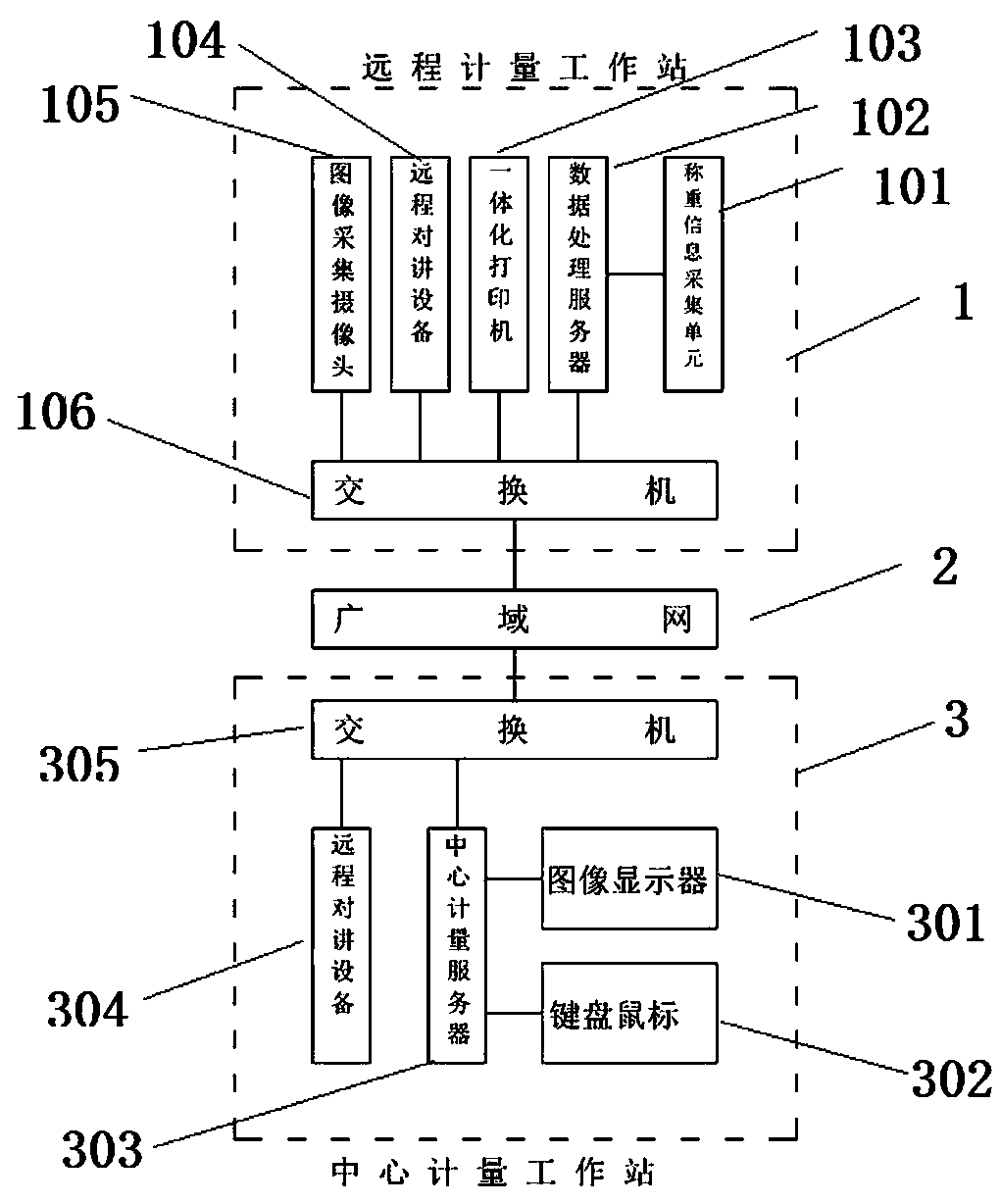

[0031] see figure 1 It can be seen that a remote intelligent metering management system for steel plant logistics through the wide area network 2 of the present invention is composed of a remote metering workstation 1, a wide area network 2 and a central metering workstation 3; the remote metering workstation 1 is electrically connected with the central metering workstation 3 through the wide area network 2, The remote metering workstation 1 is installed at each discrete metering site, the central metering workstation 3 is arranged in the central control room, and the remote metering workstation 1 is equipped with a weighing information acquisition unit 101, a data processing server 102, an integrated printer 103, a remote intercom device 104, Image acquisition camera 105 and switch 106, data processing server 102, integrated printer 103, remote intercom device 104, image acquisition camer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap