Capacitive sensor stability testing device

A technology for capacitive sensor and stability testing, applied in instruments and other directions, can solve problems such as capacitive sensor detection, and achieve the effects of accurate testing, simple structure, and high testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Stability test of capacitive sensor with standard size.

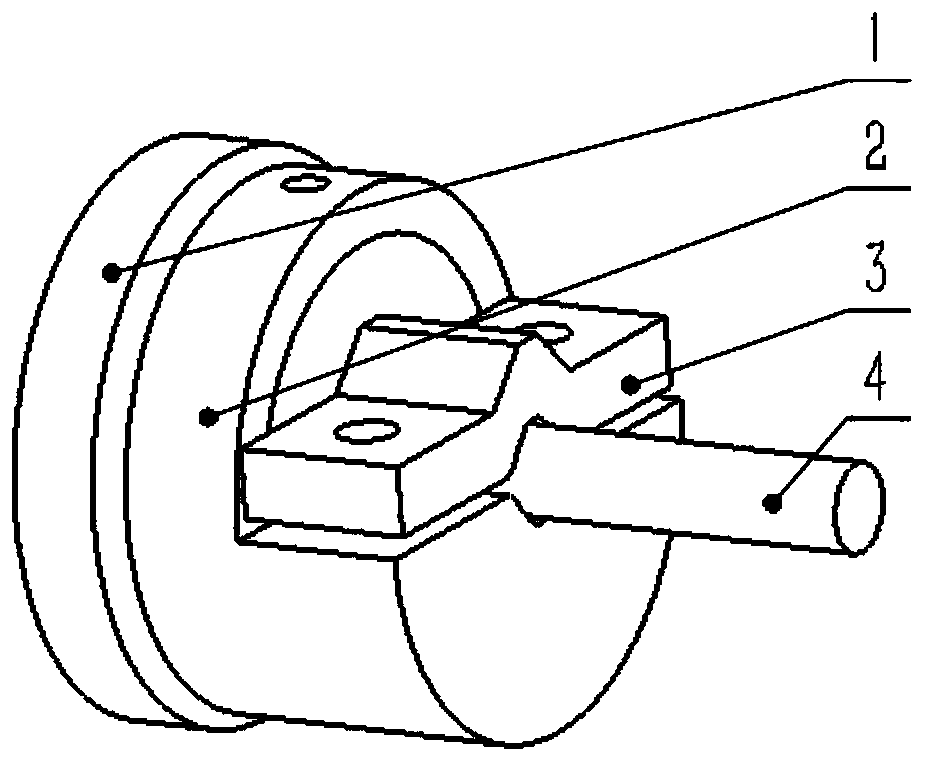

[0034] like figure 1 As shown, the stability test method of the capacitive sensor of the present embodiment is as follows:

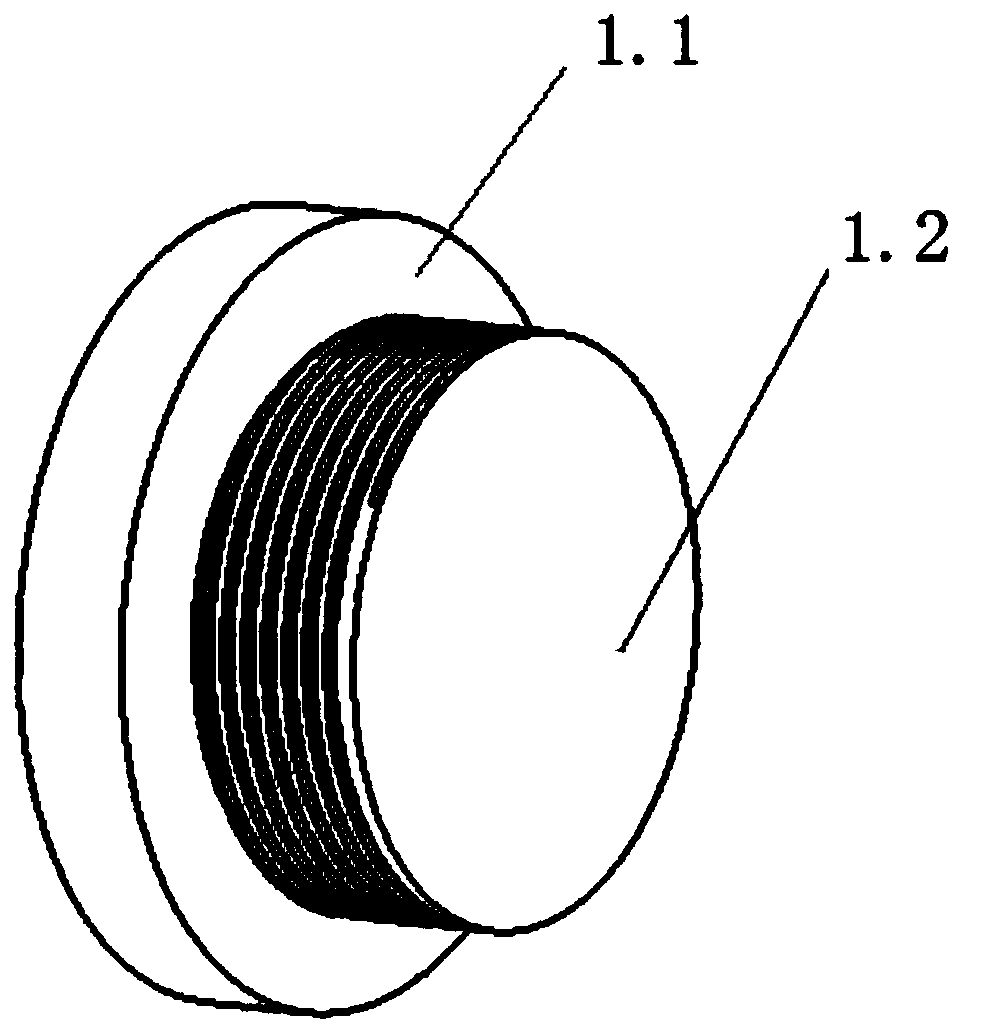

[0035] S1. Tighten the external thread on the peripheral surface of the second cylinder 1.2 and the internal thread on the inner surface of the connecting ring 2.1 to complete the connection between the base 1 and the connecting body 2;

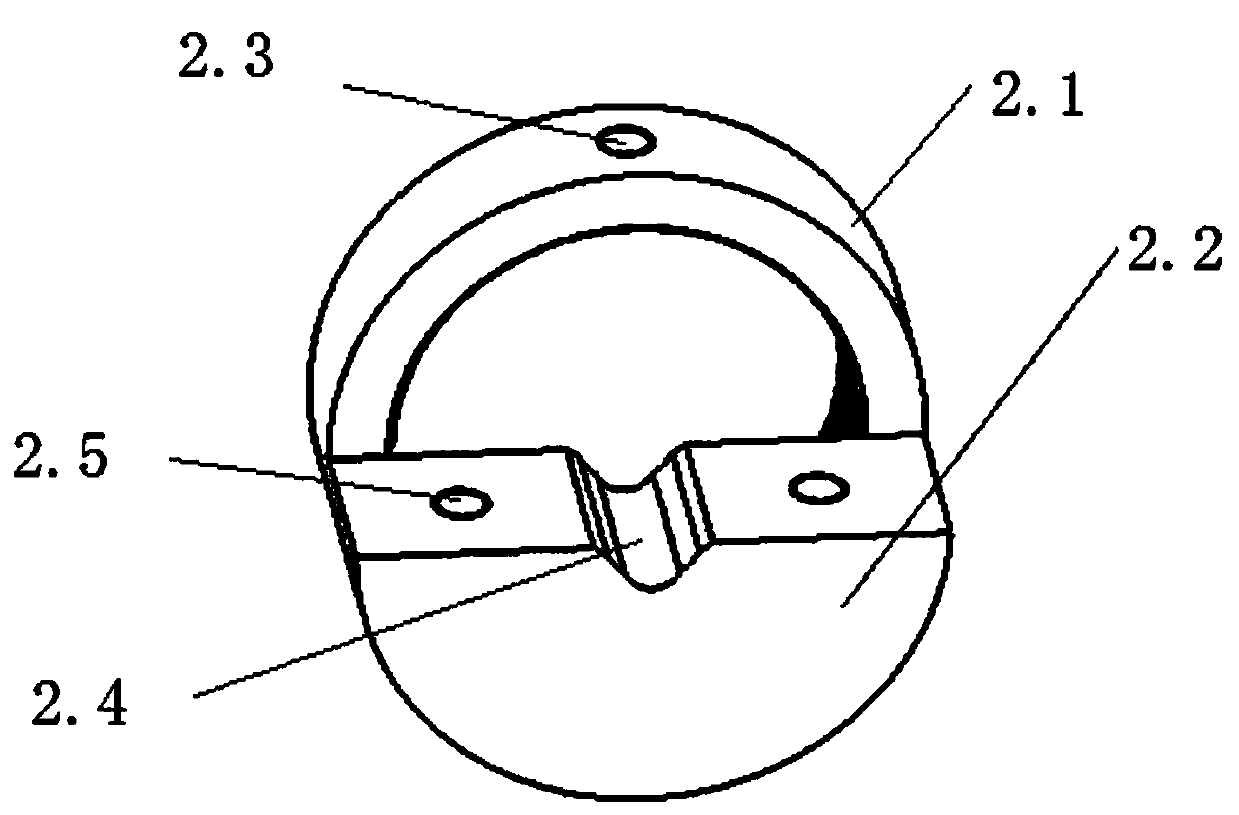

[0036] S2. Put the capacitive sensor 4 into the first through groove 2.4 of the connecting body 2. The working surface of the capacitive sensor 4 faces the base 1. By rotating the second cylinder 1.2, the working surface of the capacitive sensor 4 is aligned with the second cylinder 1.2. The distance between the grinding surfaces remains within the working range of the capacitive sensor 4;

[0037] S3, tighten the second screw in the threaded through hole 2.3 of the connecting body 2;

[0038]S4. Fasten the bottom of the upper cover 3 to t...

Embodiment 2

[0040] Embodiment 2: Stability test of a micro-sized capacitive sensor.

[0041] like Figure 5 As shown, the stability test method of the capacitive sensor of the present embodiment is as follows:

[0042] S1. Tighten the external thread on the peripheral surface of the second cylinder 1.2 and the internal thread on the inner surface of the connecting ring 2.1 to complete the connection between the base 1 and the connecting body 2;

[0043] S2. Put the capacitive sensor 4 into the first through groove 2.4 of the connecting body 2. The working surface of the capacitive sensor 4 faces the base 1. By rotating the second cylinder 1.2, the working surface of the capacitive sensor 4 is aligned with the second cylinder 1.2. The distance between the grinding surfaces remains within the working range of the capacitive sensor 4;

[0044] S3. Tighten the screw in the threaded through hole 2.3 of the connecting body 2;

[0045] S4. Buckle the top of the upper cover 3 downwards onto th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com