Range hood

A range hood and air inlet technology, applied in the field of range hood, can solve the problems of inconvenient disassembly and cleaning of the overall structure, easy accumulation of grease on the filter screen, etc., and achieve the effect of improving the filtering effect and keeping the cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

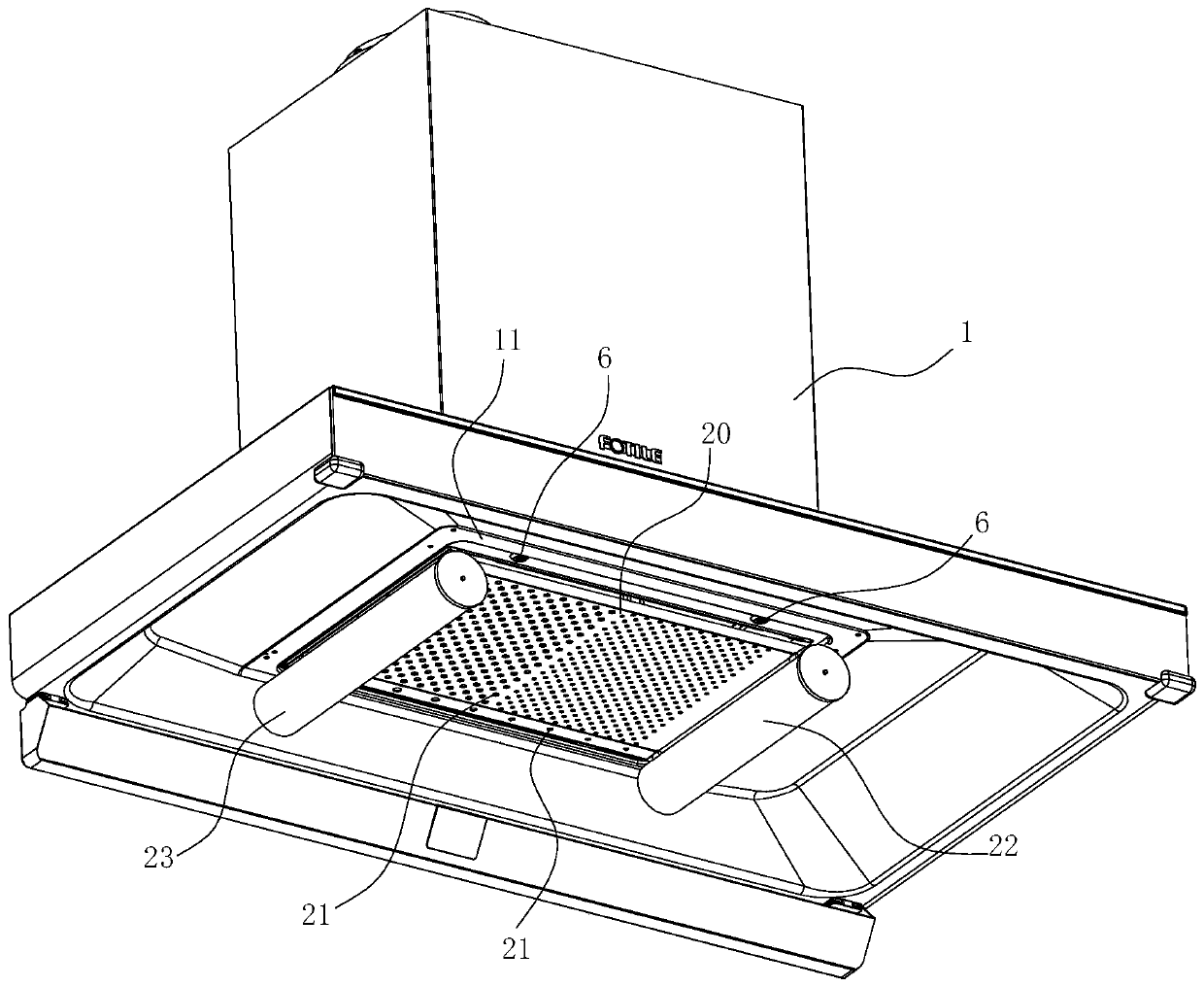

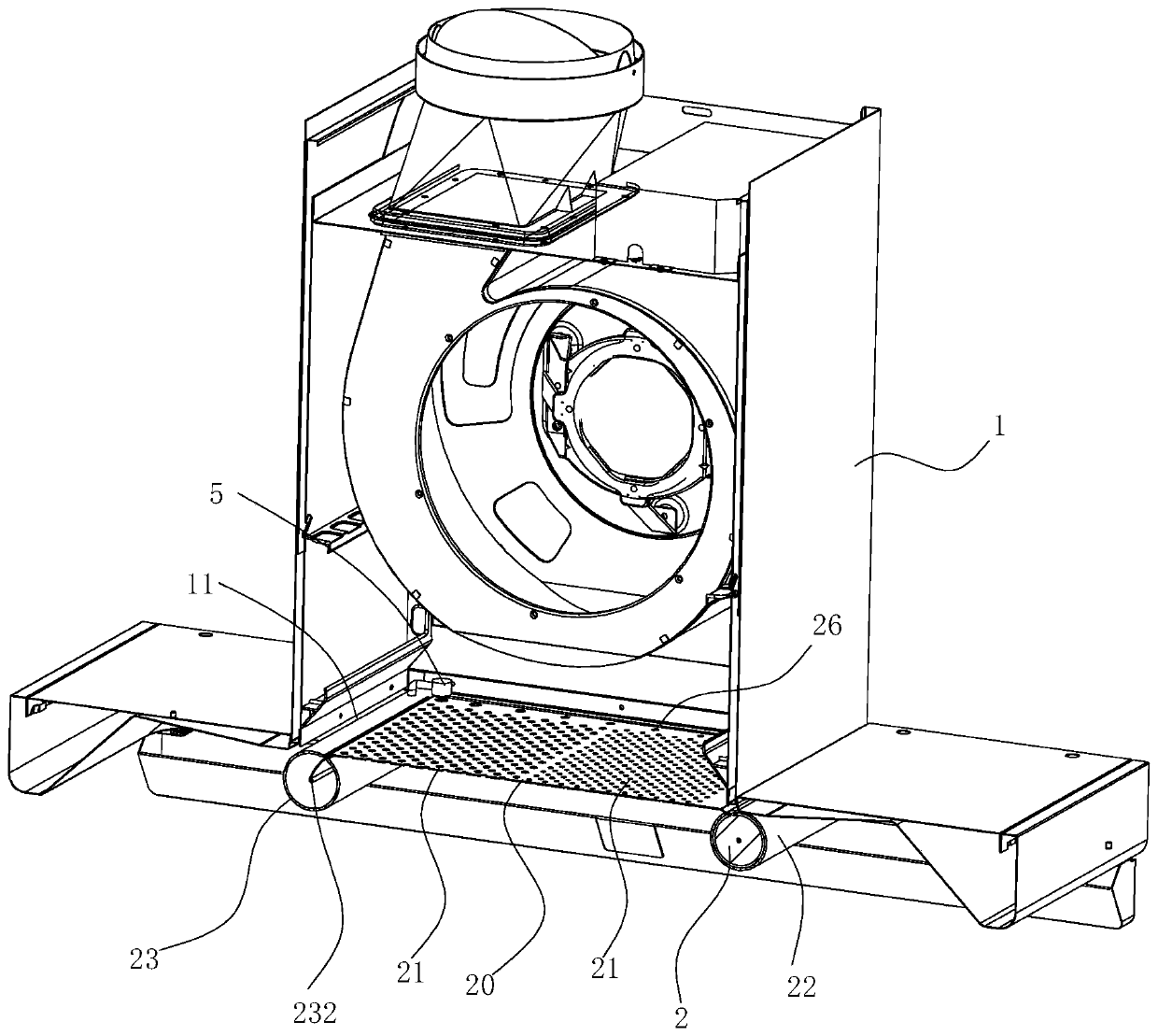

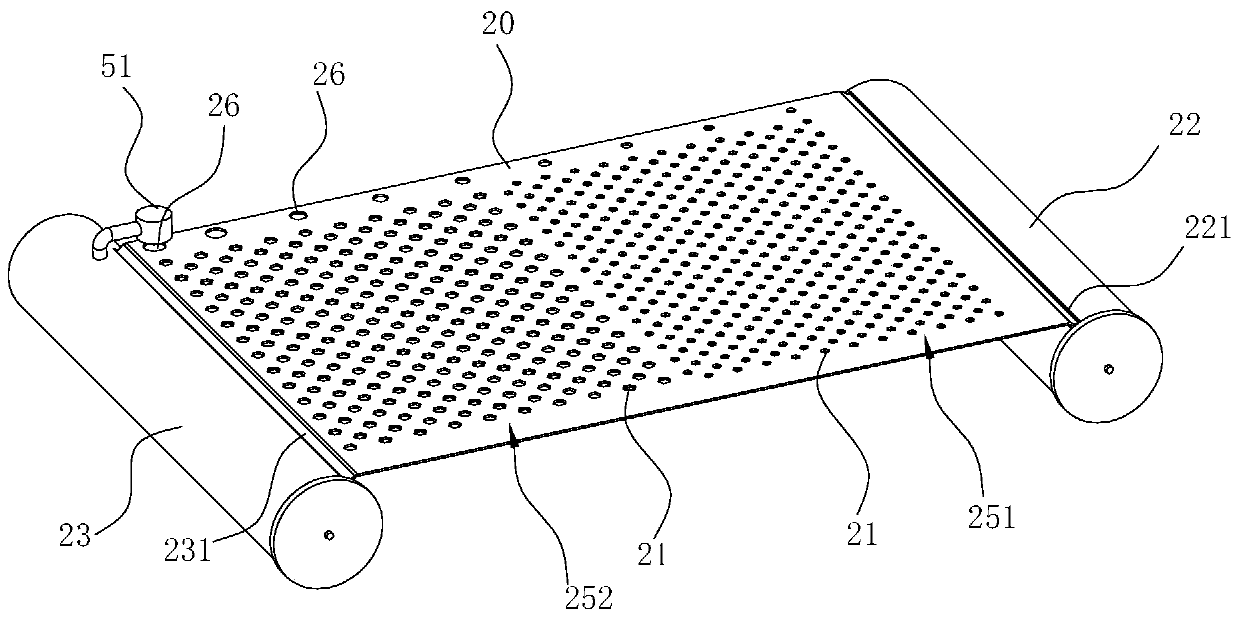

[0022] Such as Figure 1~6 As shown, the range hood of this embodiment includes a housing 1, a filter screen 20 and a driving member 3. The bottom of the housing 1 has an air inlet 11, and the filter screen 20 is made of flexible flame-retardant paper. There are several filter holes 21 of different sizes, such as figure 2 As shown, the flexible flame-retardant paper is rolled around one edge to form a roll paper structure 2 that is gradually stacked from inside to outside. The axial length of the roll paper structure 2 matches the width of the air inlet 11 . The paper roll structure 2 is rotatably arranged on the casing 1 and the axial direction of the paper roll structure 2 extends along the first width edge of the air inlet 11, and the free end of the paper roll structure 2 faces the first width of the air inlet 11. The second width edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com