Tube sheet waterproof sealing gasket

A waterproof gasket and gasket technology, used in wellbore lining, tunnel lining, underground chambers, etc., can solve the problem of inability to comprehensively prevent the leakage of mud and water, so as to facilitate embedding of water-swelling materials, improve extrusion force, strengthen The effect of glue adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

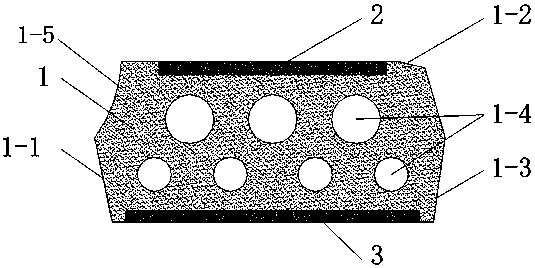

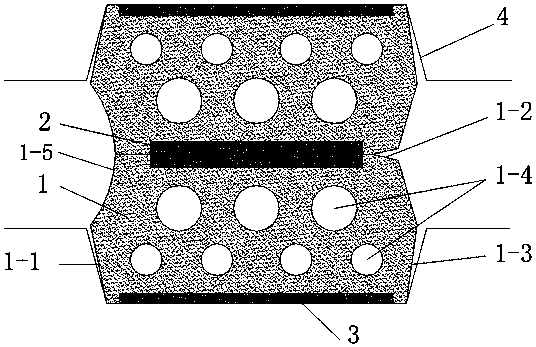

[0032] Embodiment 1, a kind of segment waterproof gasket, such as figure 1 As shown, it includes a gasket body 1 arranged in the segment sealing groove 4. The upper end surface of the gasket body 1 is provided with an upper water-swellable pad 2, and the lower end surface is provided with a lower water-swellable pad 3. The gasket body 1. The upper water-swellable pad 2 and the lower water-swellable pad 3 form a three-time water-stop structure. Such as figure 2 As shown, when the adjacent segments are squeezed against each other, the upper end surfaces of the adjacent gasket bodies 1 are attached to each other.

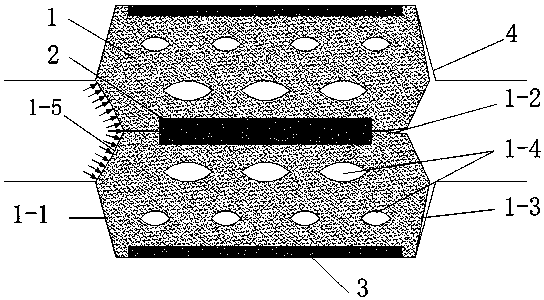

[0033] Such as image 3 As shown, when the gasket body 1 is assembled with the segments, at the same time, due to the ductility of the gasket body 1, it forms a first-level pre-tightening force after being squeezed, and plays the first water-stopping effect.

[0034] Such as Figure 4 As shown, when the water pressure on the gasket body 1 is too large or the segme...

Embodiment 2

[0036] Embodiment 2, a segment waterproof gasket, the first water-stopping effect is the same as that of Embodiment 1, which is ensured by the ductility of the gasket body 1 . The second water stop effect is as follows: Figure 6 As shown, when the water pressure on the gasket body 1 is too large or the segment joints are opened, the mutual extrusion force between the two gaskets at the ends of the two segments decreases, and the muddy water flows from the gasket body 1 The lower end face of the lower surface of the seal groove 4 penetrates between the bottom wall of the sealing groove 4 until it reaches the lower water-swellable pad 3, and the lower water-swellable pad 3 stimulates the expansion performance under the action of water, which improves the extrusion force between the gaskets, thereby Achieve the second water stop effect.

[0037] With the change of the external environment or / and the aging and deformation of the material itself, when the extrusion force excited ...

Embodiment 3

[0039] Embodiment 3, a segment waterproof gasket, the upper water-swellable gasket 2 is embedded on the upper end surface of the gasket body 1, and the lower water-swellable gasket 3 is embedded on the lower end surface of the gasket body 1.

[0040] The mosaic structure design of the bottom water-swellable pad 3 not only enables the bottom water-swellable pad 3 to be closed between the gasket body 1 and the bottom wall of the sealing groove 4, but also prevents the bottom water-swellable pad 3 from meeting before the segments are connected. Water swells, and only when the water pressure is too high or the segment joints are opened, muddy water will seep between the gasket body 1 and the bottom wall of the sealing groove 4, and the water-swellable pad 3 will be stimulated to expand when it encounters water.

[0041] The inlaid structure design of the upper water-swellable pad 2 makes the five surfaces of the upper water-swellable pad 2 wrapped in the gasket body 1, which effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com