Independent hole carving system used for embroidery machine

An embroidery machine and hole carving technology, which is applied to the mechanism of embroidery machines, embroidery machines, and automatic control embroidery machines, etc. It can solve the problem of poor hole carving effect, inability to take into account both hole carving and multi-color embroidery, and lack of multi-color embroidery, etc. problems, to achieve the effect of large choice, flexible use, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

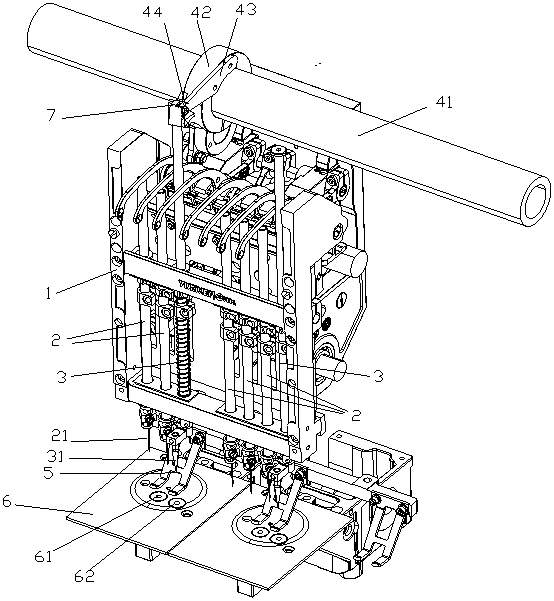

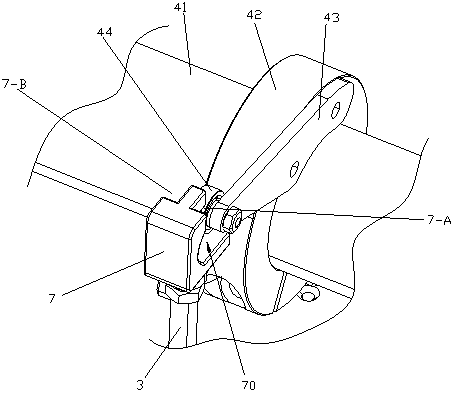

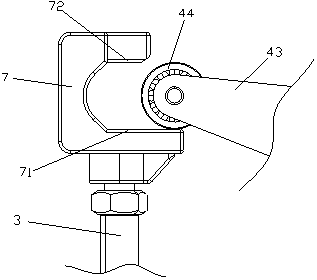

[0034] refer to figure 1 , this implementation case is used for the independent carving system of the embroidery machine, including the needle bar frame 1, the needle bar, and the driving system for carving holes. The needle bar frame 1 can translate left and right, and all the needle bars are installed on the needle bar frame 1. In this embodiment, this independent carving system is set as a "4+3" structural mode, The right side of the needle bar frame 1 is set: "4" bar, and the left side of the needle bar frame 1 is set with "3" bar, and the "4" bar is used to execute the following 4 colors (including 4 colors) For multi-color embroidery, the "3" bar is used to perform multi-color embroidery of less than 3 colors (including 3 colors). "3" bar and "4" bar, select the needle bar assembly carving knife 31 located on the far right as the hole carving bar, which is denoted as needle bar 3 here, and other needle bar assembly embroidery needles 21 are denoted as needle bar here. ...

Embodiment example 2

[0042] In this implementation case, except that the installation methods of the needle bar 3 and the carving knife 34 are different, the others are the same as the implementation case 1. refer to Figure 6 , in this implementation case, the bottom end of the needle bar 3 is directly equipped with a carving knife 34. Compared with the implementation case 1, the space at the bottom of the needle bar 3 is more abundant, which is beneficial to the overall structural adjustment, and at the same time does not Affect the removal of the carving knife 34 and replace it with an embroidery needle.

Embodiment example 3

[0044] In this implementation case, except that the return spring is different in the connection relation of the needle bar, the others are the same as the implementation case 1. refer to Figure 7 , in this implementation case, the needle bar 3 is provided with a return spring 3-B, the return spring 3-B, and the two ends of the return spring 3-B are respectively connected to the top of the needle bar 3 and the needle Mid-range 12 for rod holders. Likewise, the connection mode between the needle bar 2 and the back-moving spring is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com