Material sequence control method applied to high-proportion pellet smelting

A control method, a high-proportion technology, applied in steel manufacturing process, blast furnace, blast furnace details, etc., can solve problems affecting the stable distribution of gas in the furnace, performance impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

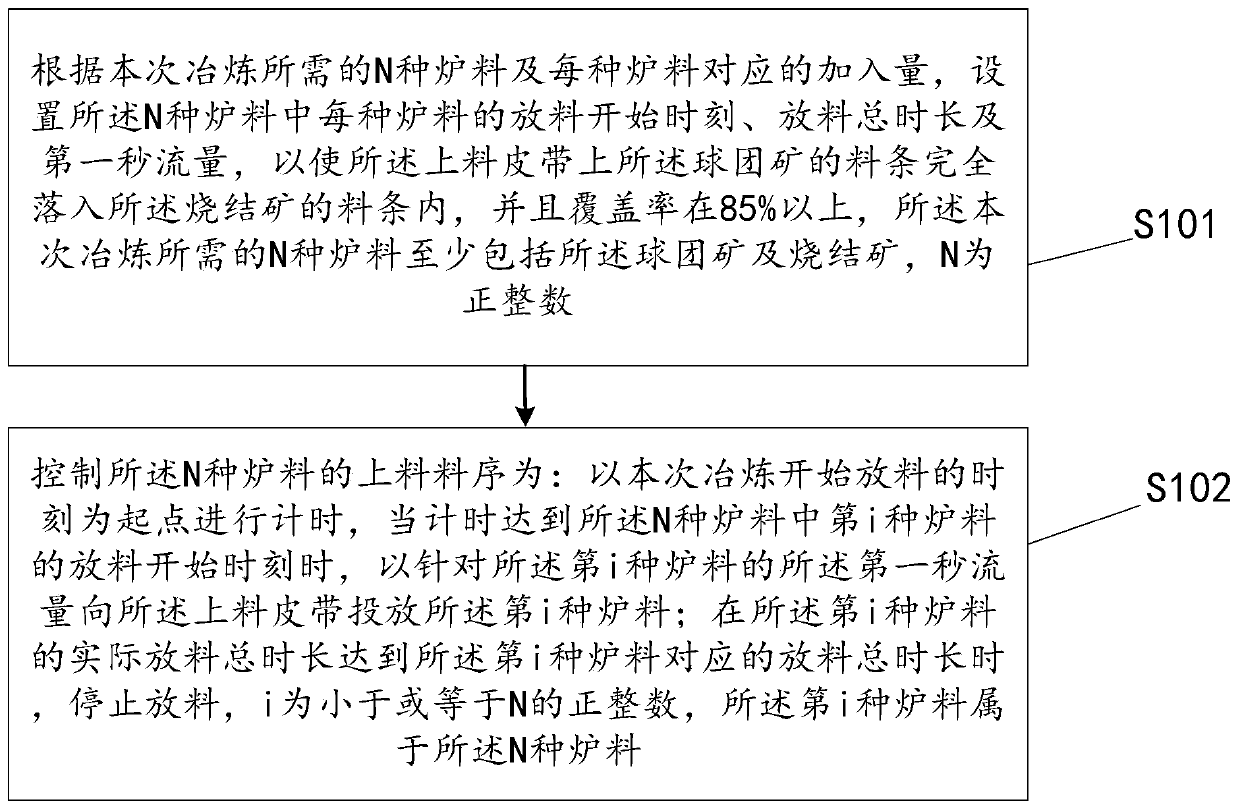

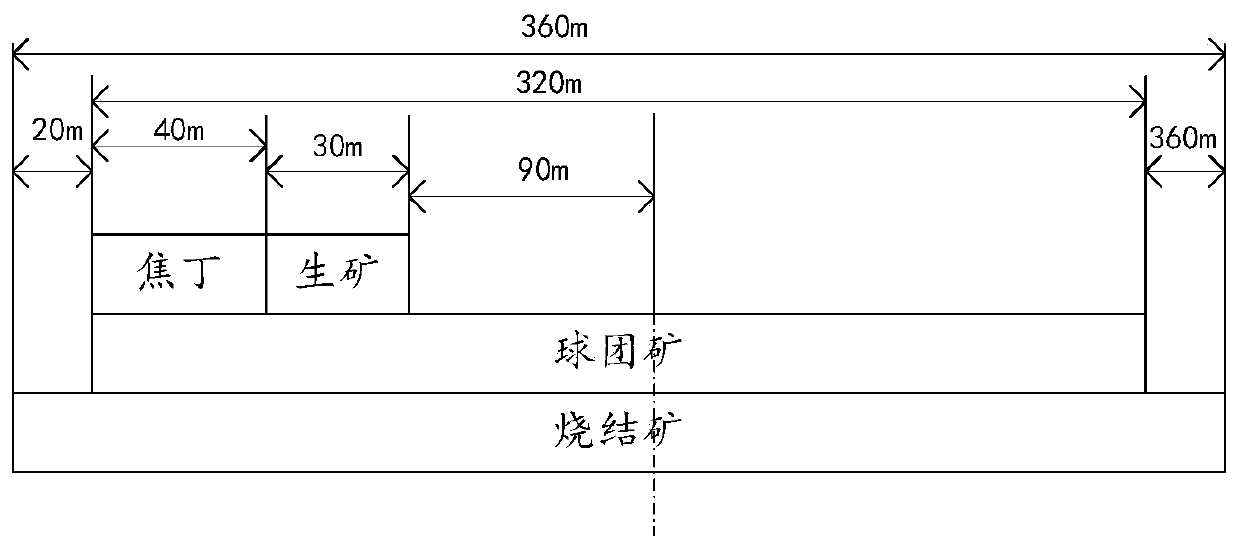

[0021] The embodiment of the present application provides a material sequence control method applied to high-proportion pellet smelting, which solves the impact of the difference in performance of the two materials, pellet ore and sinter, on blast furnace smelting during the high-proportion pellet smelting process , especially technical issues that affect the stable distribution of gas in the furnace.

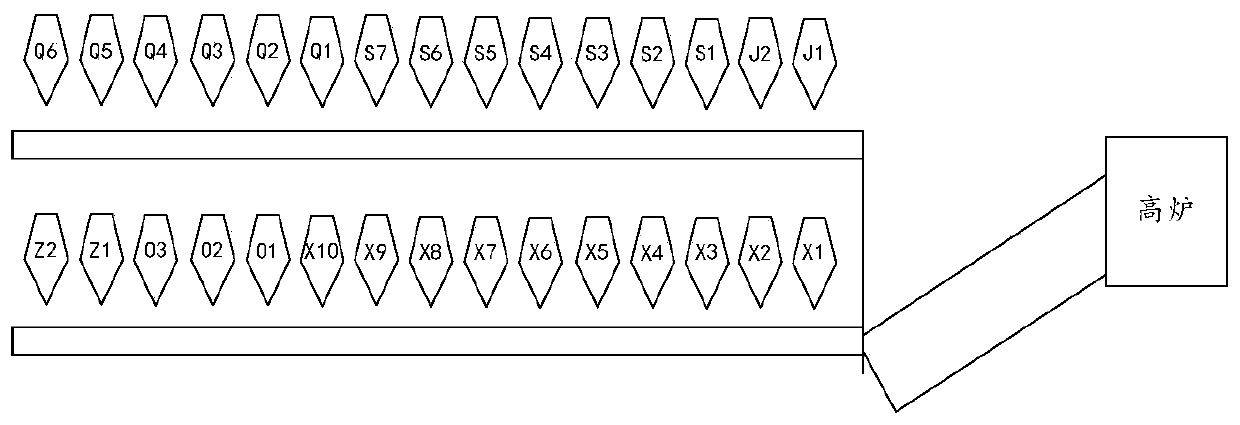

[0022] The technical solution of the embodiment of the application is to solve the above technical problems. The application provides a material sequence control method applied to the smelting of high-proportion pellets. In more than 40% of the feeding systems, in practical applications, the feeding system includes a feeding belt and a silo evenly arranged above the feeding belt, and the silo is used to classify and store the materials required for this smelting. of various furnace materials. The silo and feeding belt of the feeding system in the furnace smelting such as figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com