AGV injection molding feeding and discharging basket changing machine

A material basket and material port technology, which is applied in the field of AGV injection molding, loading, unloading, and changing baskets, can solve the problems of labor consumption, high work intensity, and difficulty in recruiting, saving labor costs, reducing cleaning costs, and not easily contaminated with dirt. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

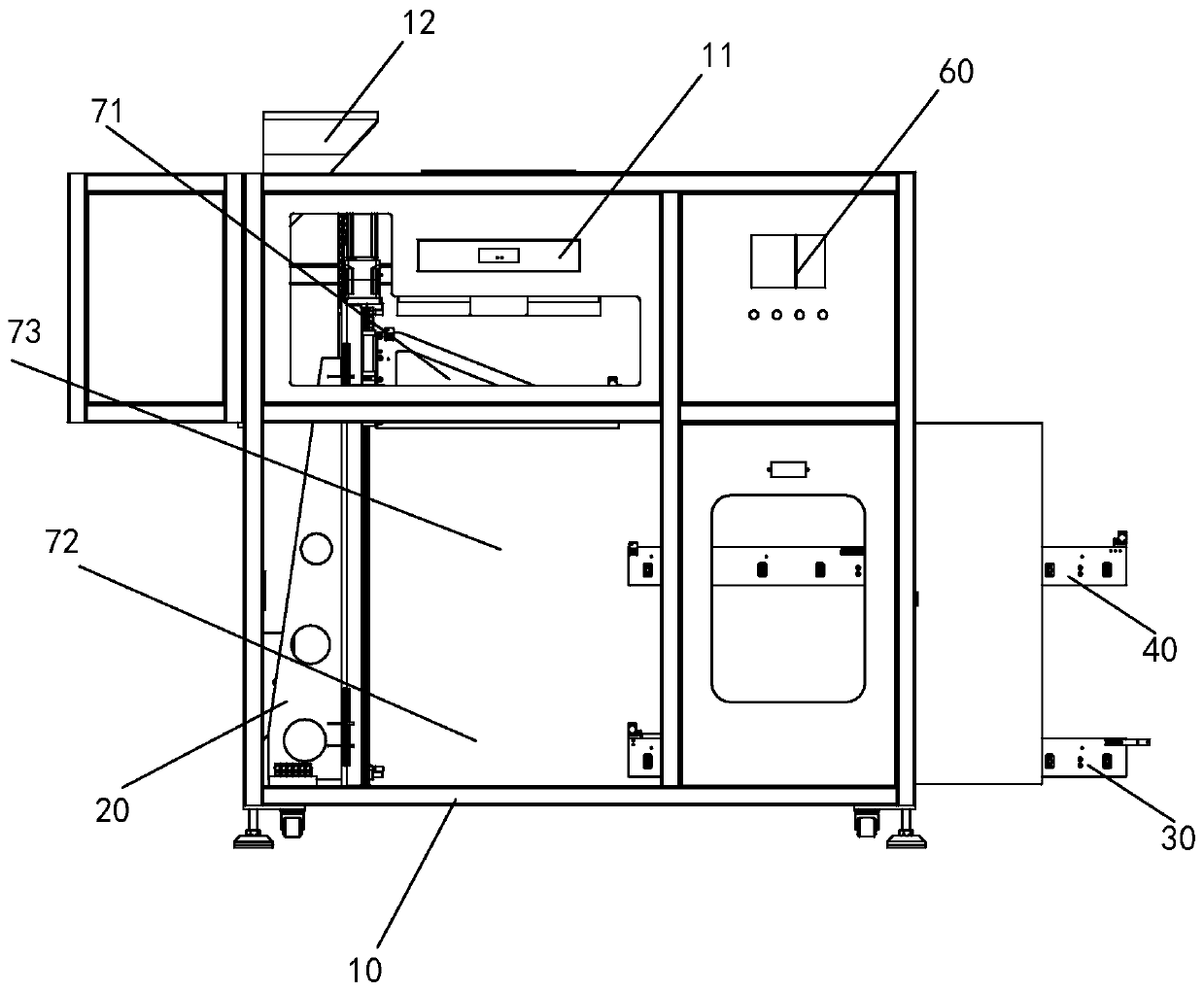

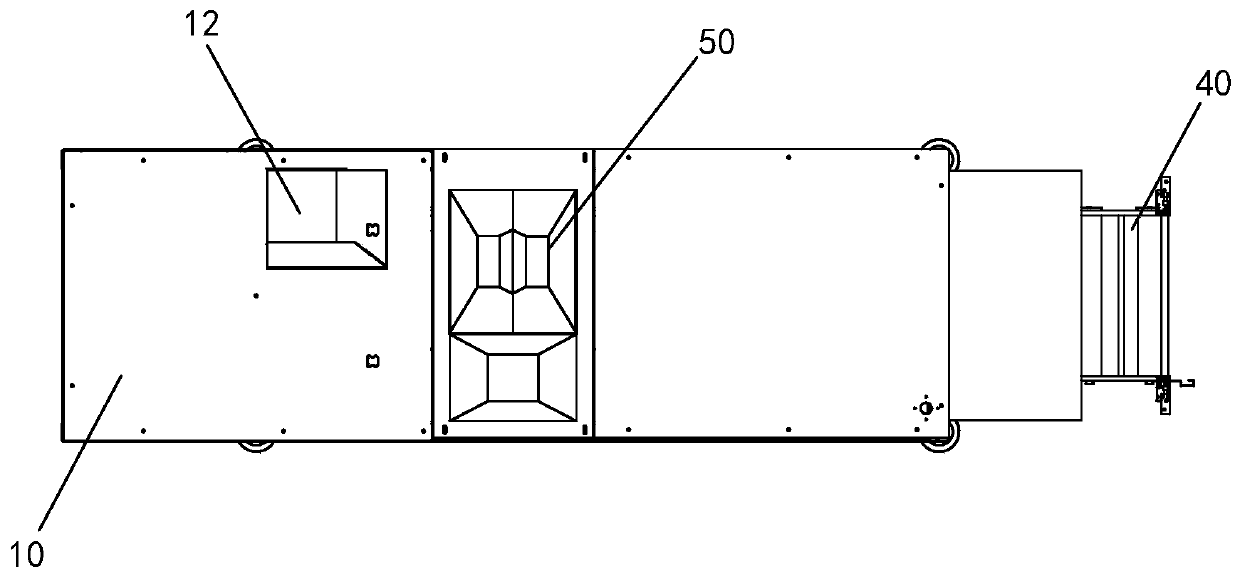

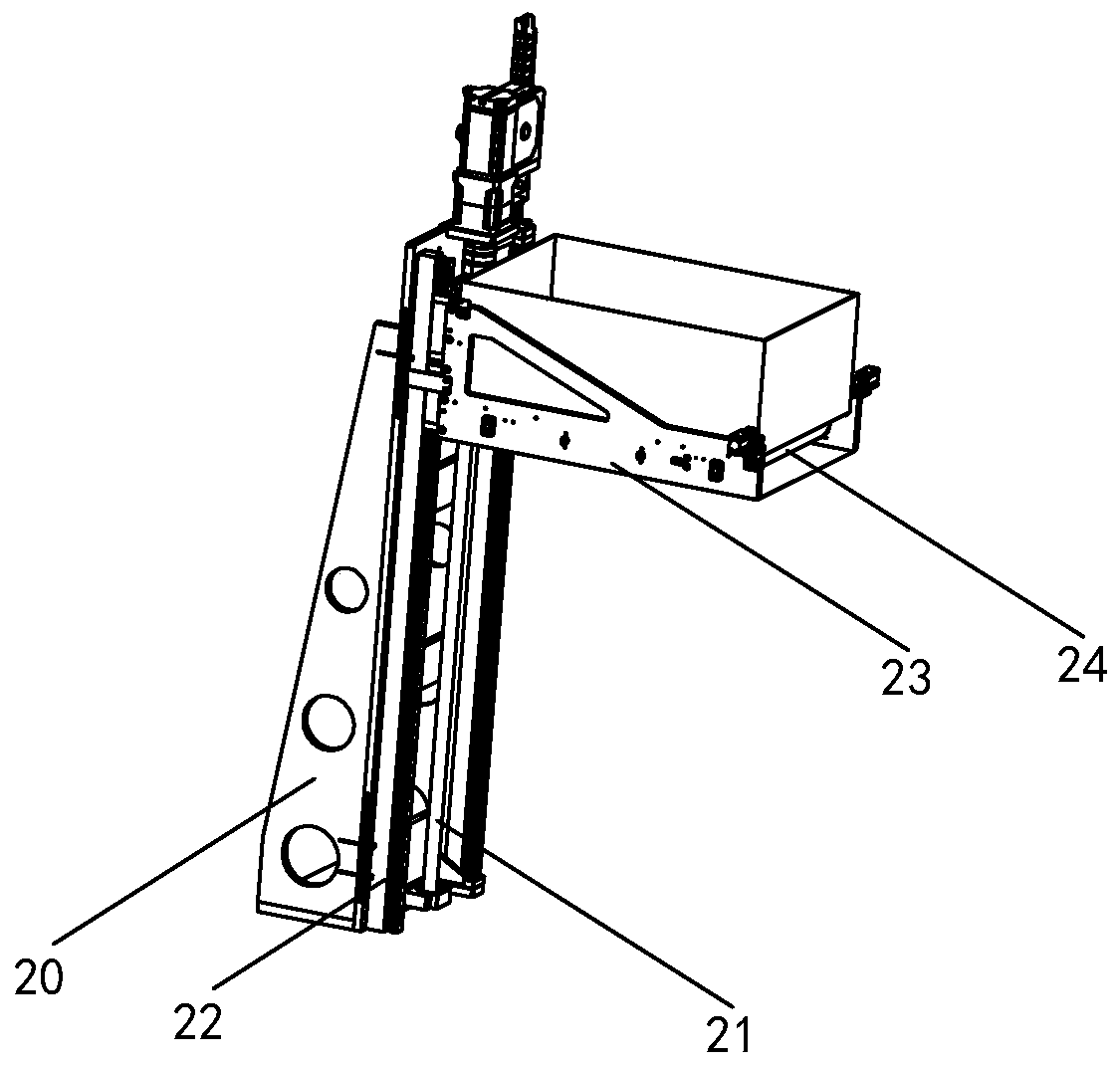

[0029] Examples, see Figure 1 to Figure 5 As shown, a kind of AGV injection molding loading and unloading basket changing machine of the present invention, it comprises frame 10 and the lifting mechanism 20 that is installed on described frame 10, enters the basket conveyer belt 30, goes out the basket conveyer belt 40, unloading port 50 and control Module 60, the feeding opening 50 is arranged above the frame 10, the lifting mechanism 20 is a screw 21 lifter arranged below the feeding opening 50, and the screw 21 lifting includes a servo motor Driven screw mandrel 21, slide rail 22 and slide block 23 slidably installed on the slide rail 22, the slide block 23 is provided with a basket conveyor belt 24 for carrying material baskets, and the control module 60 controls The servo motor controls the lifting mechanism 20 to drive the material basket to move up and down and switch between the receiving position 71, the basket entering position 72 and the basket exiting position 73....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com