Anti-shedding tile forming mold

A forming mold and anti-shedding technology, which is applied in the direction of ceramic forming core, ceramic forming machine, ceramic forming mandrel, etc., can solve the problems of inconvenient demoulding, insufficient anti-stripping force, cumbersome design of pressing mold, etc., and achieve low cost and easy The effect of demoulding and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

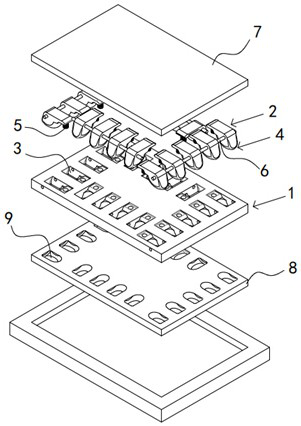

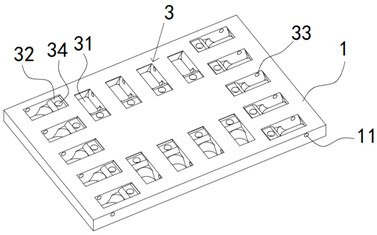

[0026] Such as Figures 1 to 5 As shown, the anti-falling tile forming mold includes a mold case 1 and a mold core 2, the mold core 2 is embedded in the mold case 1, and the mold case 1 is provided with eighteen placement cavities 3, and the eighteen placement cavities 3 are symmetrical in pairs And arranged in a "mouth" shape, the eighteen placement cavities 3 are four on each side of the longitudinal direction, and five on each side of the transverse direction. Each placement cavity 3 is provided with a mold core 2, and the bottom of the placement cavity 3 is provided An inclined hole 31, one end of the placement cavity 3 is provided with an elastic force receiving part 32, and both sides of the cavity wall of the placement cavity 3 are provided with placement cavity installation holes 33;

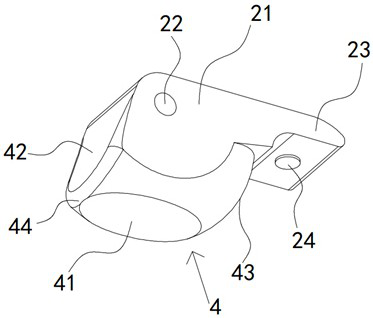

[0027] The mold core 2 includes a fixed installation part 21, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com