A high-efficiency continuous coated sand mixing device

A continuous type, coated sand technology, applied in foundry molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc. High efficiency and good sand mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

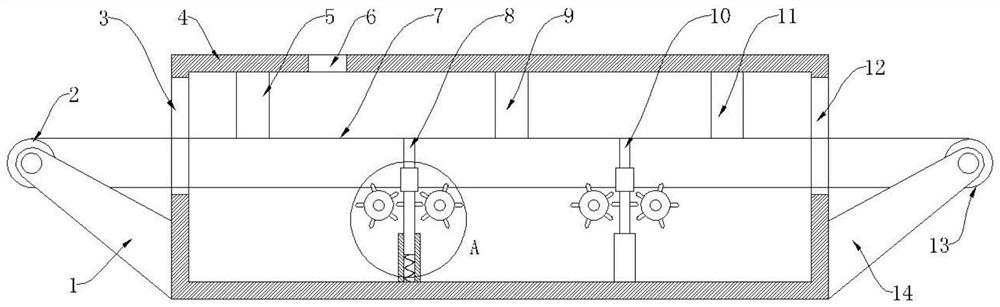

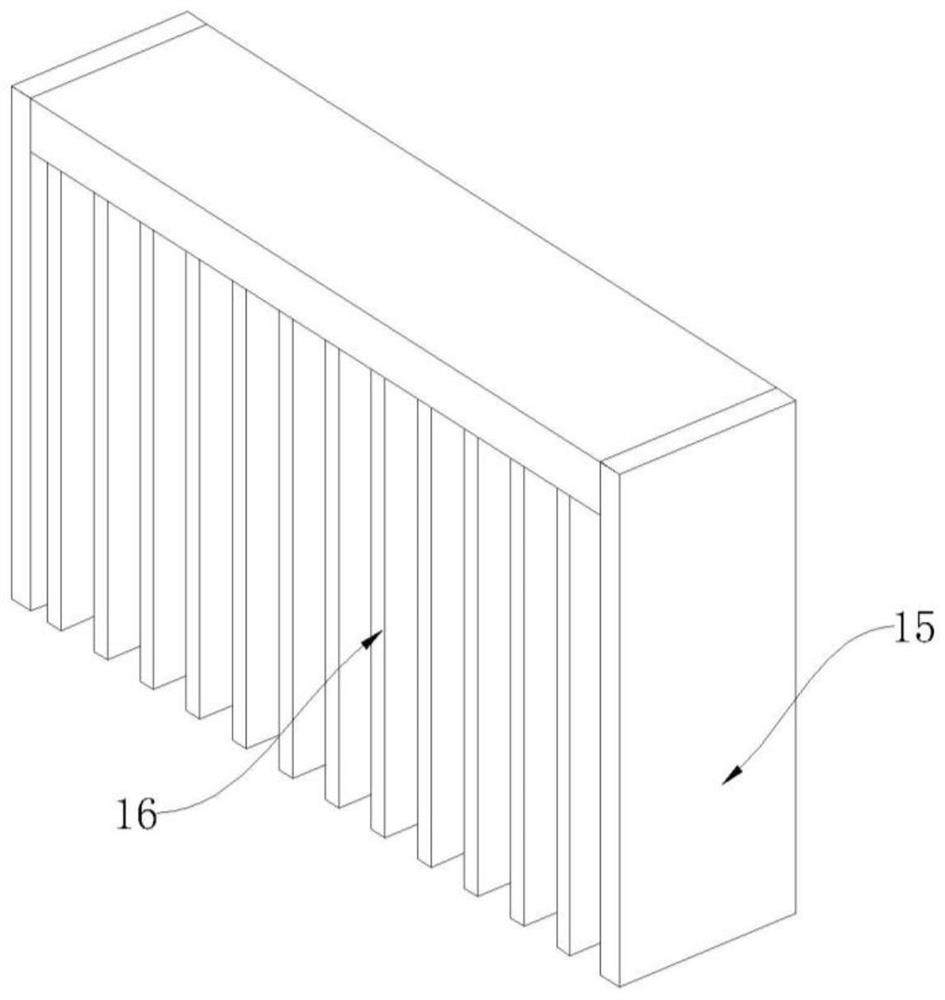

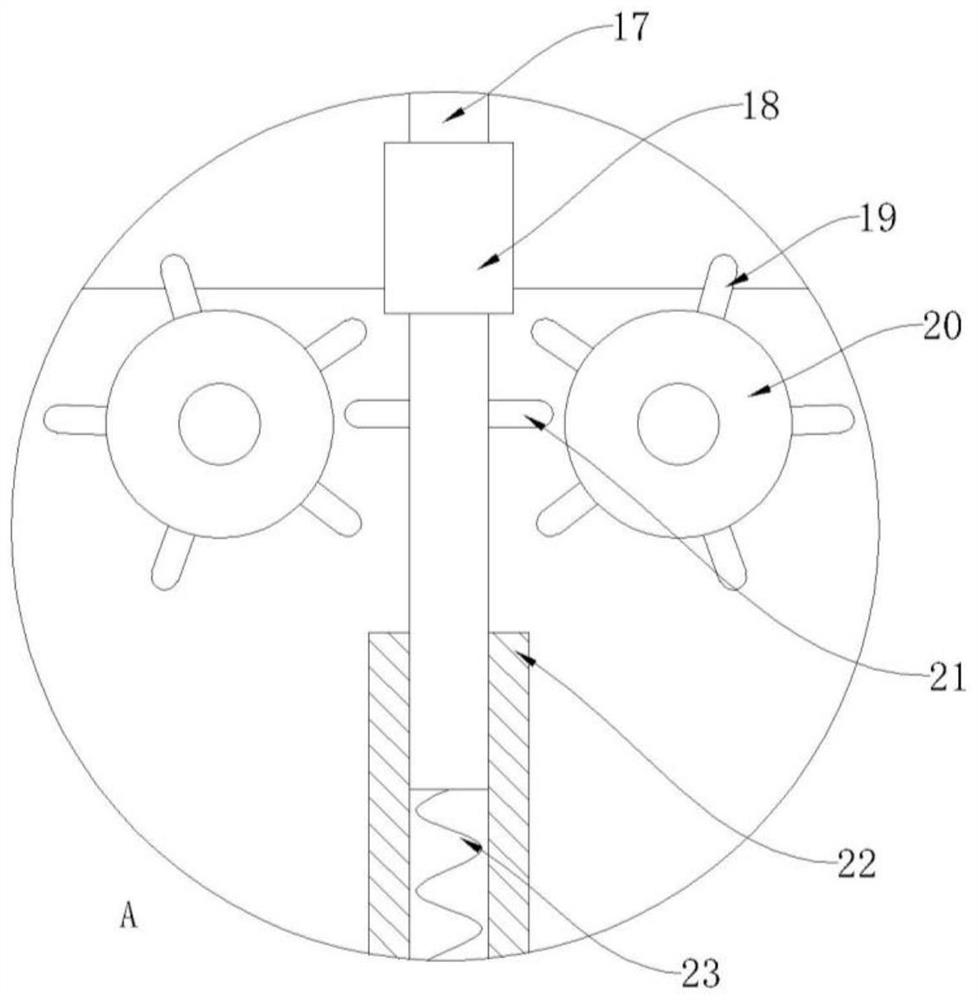

[0024] see Figure 1-3 , the present embodiment provides a high-efficiency continuous coated sand sand mixing device, comprising a box 4, one side of the box 4 is provided with a feed port 3, and the other side is provided with a discharge port 12, the box 4 A first pulley 2 is arranged on the outside of one side of the feed opening 3, and a second pulley 13 is arranged on the outside of the side of the box body 4 located at the discharge opening 12. The first pulley 2 and the first pulley 2 The second pulley 13 is sleeved and connected by a conveyor belt 7, and the conveyor belt 7 runs through the box body 4 from the feed port 3 and the discharge port 12; the upper part of the box body 4 is close to the feed port One side of the feed port 3 is provided with a batching inlet 6, and the inside of the box body 4 is provided with a first uniform material assembly 5, a second uniform material assembly 9 and a third uniform material assembly 11 at intervals along the direction of t...

Embodiment 2

[0039] see figure 1 , a high-efficiency continuous coated sand sand mixing device. Compared with Embodiment 1, the first pulley 2 is connected to the side wall of the box body 4 through the first bracket 2, and the second belt pulley The wheel 13 is connected with the side wall of the box body 4 through the second bracket 14 .

[0040] The embodiment of the present invention can realize the continuous and efficient sand mixing operation of coated sand, and has the advantages of high sand mixing efficiency and good sand mixing effect. into the box 4, the sand mixing main material is evenly spread on the upper part of the conveyor belt 7 when passing through the first homogenizing component 5, and then the sand mixing ingredients are put into the box 4 from the batching inlet 6 to mix with the sand mixing main material , use the first elastic component 8 to act on the bottom of the conveyor belt 7, thereby driving the conveyor belt 7 to vibrate, so that the main ingredient of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com