Nacre structure graphene oxide flexible film and its preparation method and application in recovery of rhenium

A flexible technology of nacre and ene, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve problems such as lengthy process flow, large environmental pollution, and application restrictions, and achieve fast and efficient reactions , high reactivity and less harsh reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

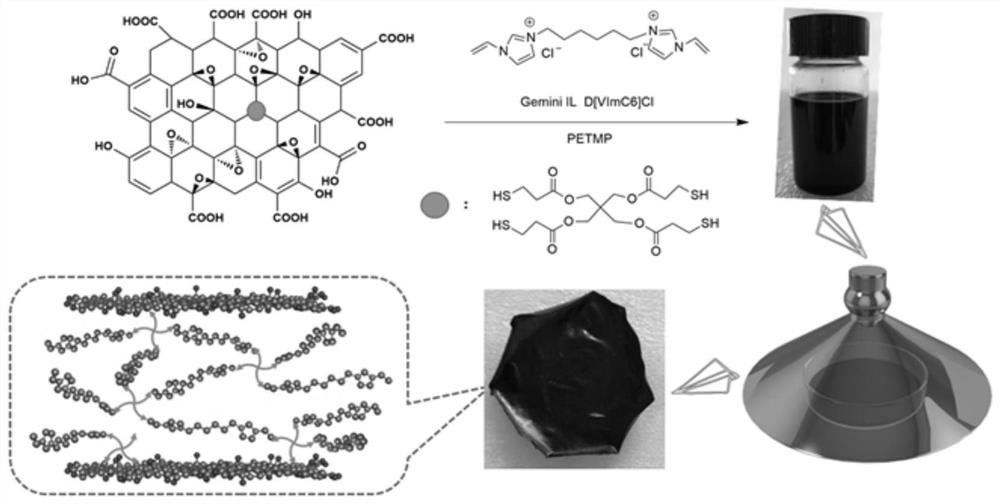

[0028] Embodiment 1 nacre structure graphene oxide flexible film (GO-1Gemini IL)

[0029] (1) The preparation method is as follows

[0030] 1) Ultrasonic disperse 50mg graphene oxide in 20mL N,N-dimethylformamide, add 100mg tetrakis(3-mercaptopropionate)pentaerythritol ester and 10mg azobisisobutyronitrile successively, and condense at 70°C under nitrogen protection Reflux reaction for 16h. After the reaction solution was centrifuged, the solid product was dispersed in 10 mL of anhydrous methanol again to obtain a dispersion.

[0031] 2) Add 5mL N,N-dimethylformamide, 200mg pentaerythritol tetrakis(3-mercaptopropionate), 20mg benzoin dimethyl ether and 350mg 1,6-bis(3) to the dispersion obtained in step 1). - Vinylimidazolium chloride) hexane (D[VImC6]Cl), after ultrasonic dispersion for 1 hour, quickly pour it into a 9cm petri dish, and irradiate it with ultraviolet light for 3 hours. After cooling, a layer of film is formed on the petri dish, and the film is washed with w...

Embodiment 2

[0034] Embodiment 2 nacre structure graphene oxide flexible film (GO-0.5Gemini IL)

[0035] 1) Ultrasonic disperse 50mg graphene oxide in 20mL N,N-dimethylformamide, add 100mg tetrakis(3-mercaptopropionate)pentaerythritol ester and 10mg azobisisobutyronitrile successively, and condense at 70°C under nitrogen protection Reflux reaction for 16h. After the reaction solution was centrifuged, the solid product was dispersed in 10 mL of anhydrous methanol again to obtain a dispersion.

[0036] 2) Add 5mL of N,N-dimethylformamide, 200mg of pentaerythritol tetrakis(3-mercaptopropionate), 20mg of benzoin dimethyl ether and 175mg of 1,6-bis(3) to the dispersion obtained in step 1). - Vinylimidazolium chloride) hexane (D[VImC6]Cl), after ultrasonic dispersion for 1 hour, quickly pour it into a 9cm petri dish, and irradiate it with ultraviolet light for 3 hours. After cooling, a layer of film is formed on the petri dish, and the film is washed with water, and then the obtained film is s...

Embodiment 3

[0037] Embodiment 3 nacre structure graphene oxide flexible film (GO-2Gemini IL)

[0038] 1) Ultrasonic disperse 50mg graphene oxide in 20mL N,N-dimethylformamide, add 100mg tetrakis(3-mercaptopropionate)pentaerythritol ester and 10mg azobisisobutyronitrile successively, and condense at 70°C under nitrogen protection Reflux reaction for 16h. After the reaction solution was centrifuged, the solid product was dispersed in 10 mL of anhydrous methanol again to obtain a dispersion.

[0039] 2) Add 5mL N,N-dimethylformamide, 200mg pentaerythritol tetrakis(3-mercaptopropionate), 20mg benzoin dimethyl ether and 700mg 1,6-bis(3) to the dispersion liquid obtained in step 1). - Vinylimidazolium chloride) hexane (D[VImC6]Cl), after ultrasonic dispersion for 1 hour, quickly pour it into a 9cm petri dish, and irradiate it with ultraviolet light for 3 hours. After cooling, a layer of film is formed on the petri dish, and the film is washed with water, and then the obtained film is soaked i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com