Steamed dumpling blank pressing die and steamed dumpling blank pressing die set

A technology for pressing molds and steaming dumpling blanks, which is applied in the directions of dough embossing machine, baking, dough processing, etc., can solve the problems of incapability of mechanized production of steamed dumpling blanks, etc., and achieves the effect of improving production efficiency, good gloss and uniform size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

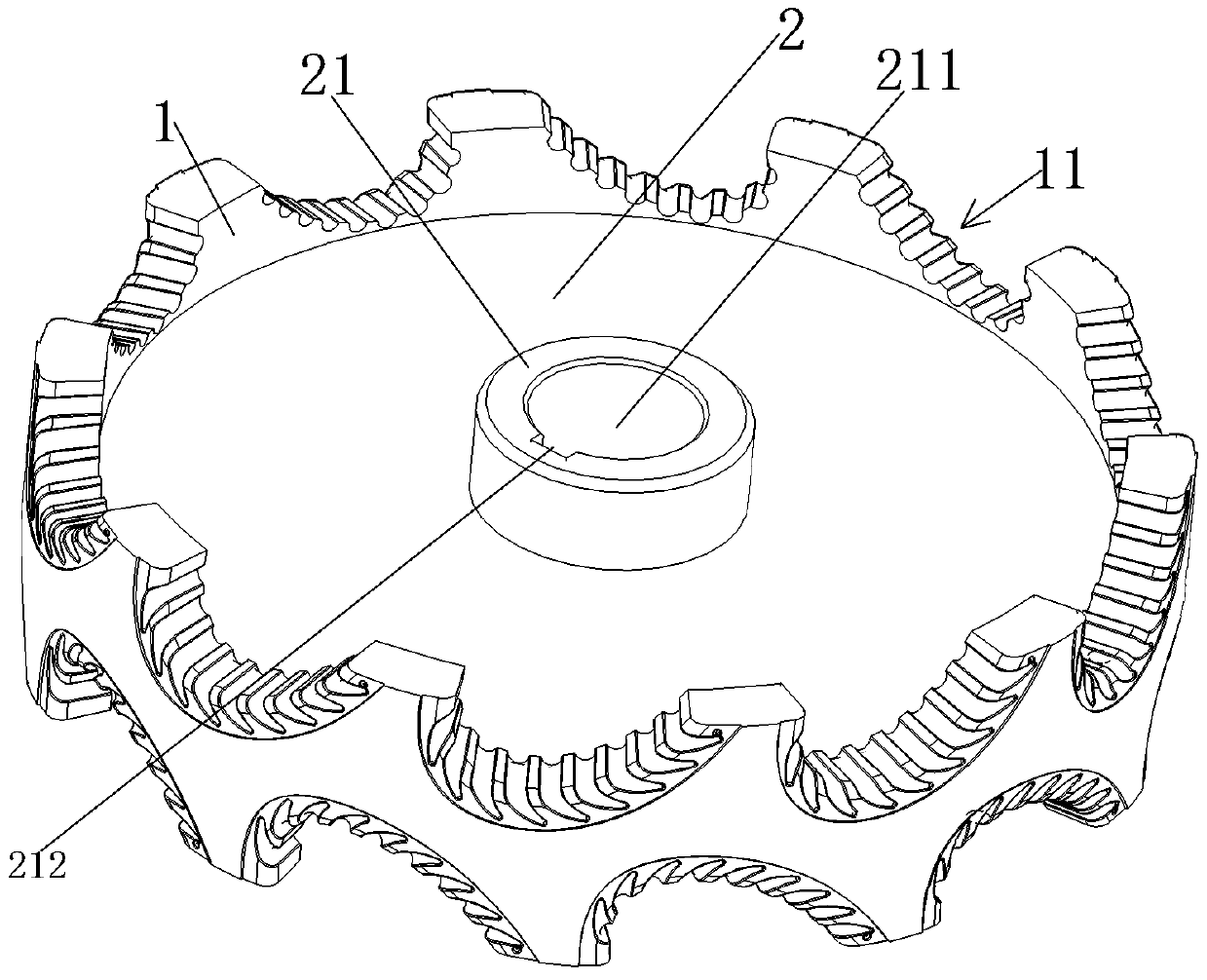

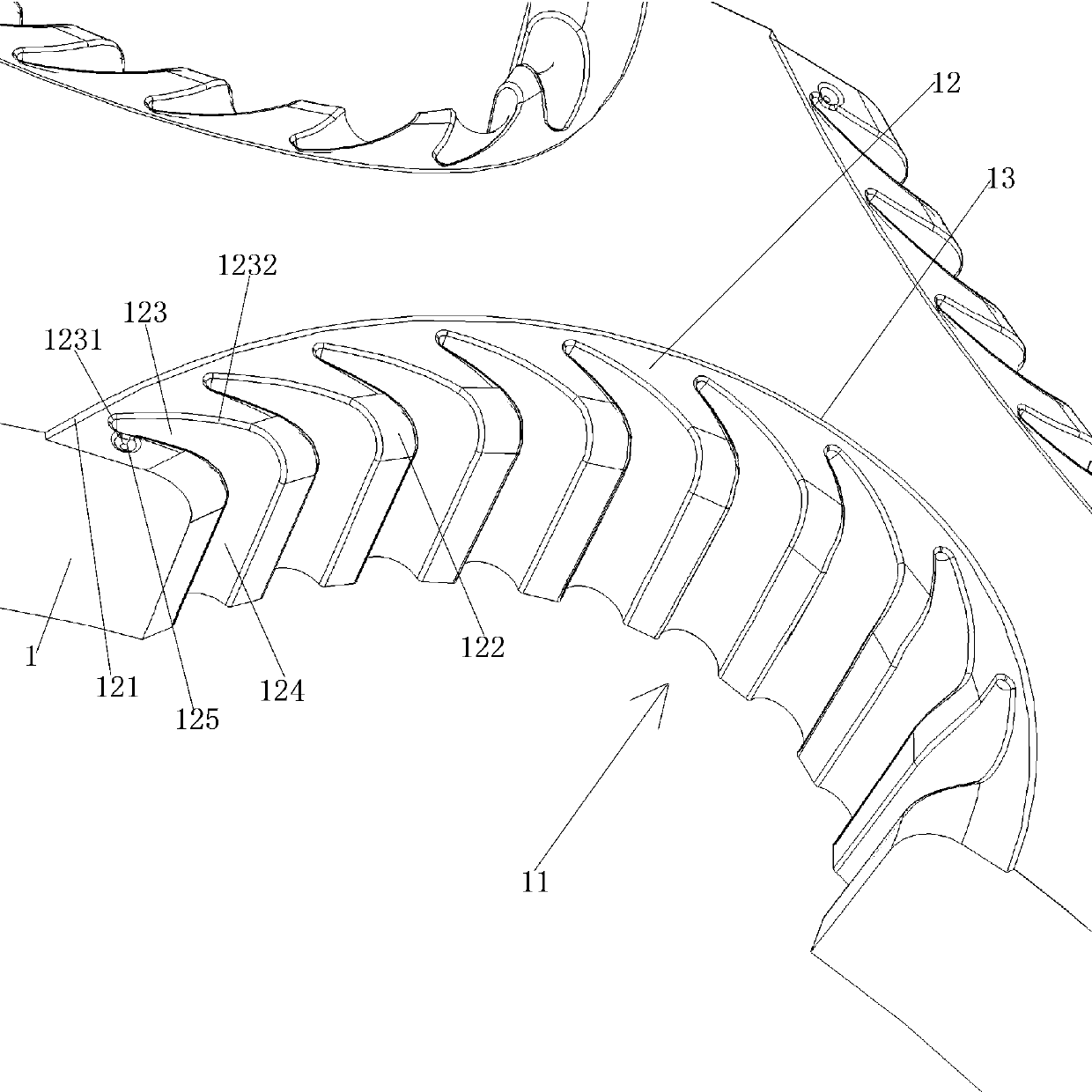

[0041] A kind of steamed dumpling blank pressing mold, please refer to Figure 1 to Figure 4 .

[0042] The steamed dumpling blank pressing mold provided by the embodiment of the present invention includes an outer ring portion 1 and an inner support portion 2, the ring portion 1 is in the shape of a ring, and the support portion 2 is a disc integrally arranged in the ring portion 1. The support part 2 mainly plays a role of supporting the ring part 1, the middle part of the support part 2 is provided with a shaft sleeve 21, the center of the shaft sleeve 21 is a shaft hole 211, and the side wall of the shaft hole 211 is provided with a keyway 212 for the The steamed dumpling base pressing mold is assembled on the rotating shaft.

[0043] The two sides of the annular part 1 are provided with a plurality of notches 11 for extruding to form dumplings. The distance between adjacent notches 11 on the same side is the same, and the notches 11 on the upper side are located in the t...

Embodiment 2

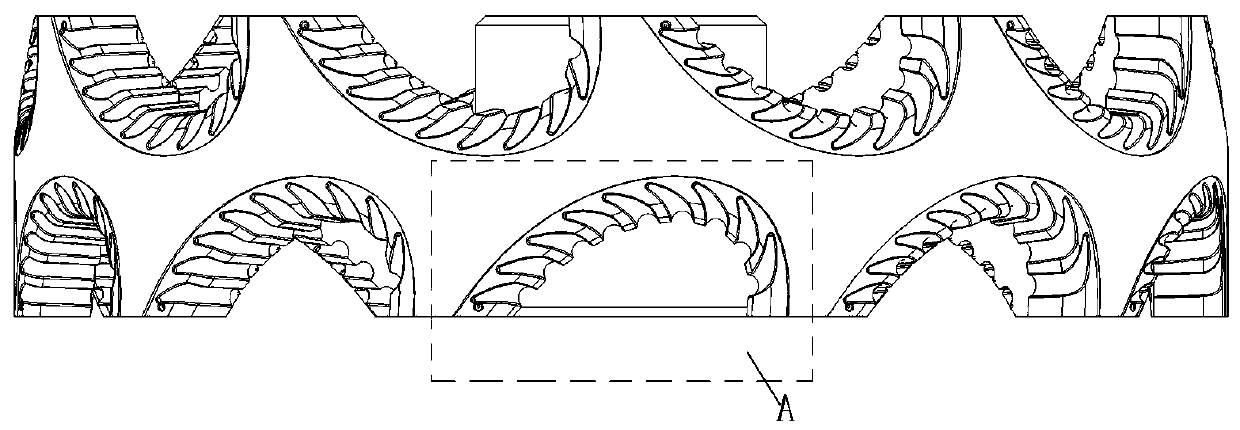

[0056] A kind of mold group for pressing steamed dumpling base, please refer to it together Figure 1 to Figure 11 .

[0057] Such as Figure 5 As shown, the steamed dumpling base pressing die set includes a left steamed dumpling base pressing die 31, a right steamed dumpling base pressing die 32, and both the left steamed dumpling base pressing die 31 and the right steamed dumpling base pressing die 32 are the steamed dumpling base pressing dies 32 in Example 1. Dumpling blank pressing mold, the outer peripheral surfaces of these two steamed dumpling blank pressing molds are bonded, wherein, such as Figure 6 Shown, the side 321 of the annular portion of the right steamed dumpling blank pressing die 32 is provided with screw holes 322, as Figure 7 As shown, a front annular rib 33 and a rear annular rib 34 are respectively connected by screws 35 on both sides of the right steamed dumpling base pressing mold 32 .

[0058] Such as Figure 5 Shown, front annular rib 33 and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com