Axle housing weld joint leakage detection device

A bridge and leak detection technology, which is applied in the direction of measuring devices, fluid tightness testing, machine/structural component testing, etc., can solve problems such as difficult leak point location, inconvenient use and operation, and affect work efficiency, and achieve easy diffusion , low background noise, low molecular weight and low viscosity coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to specific embodiments and drawings.

[0025] It should be noted that all the expressions "first" and "second" in the embodiments of the present invention are used to distinguish two entities with the same name but not the same or parameters that are not the same, as shown in "first" and "second" Only for the convenience of presentation, it should not be construed as a limitation to the embodiments of the present invention, and subsequent embodiments will not describe this one by one.

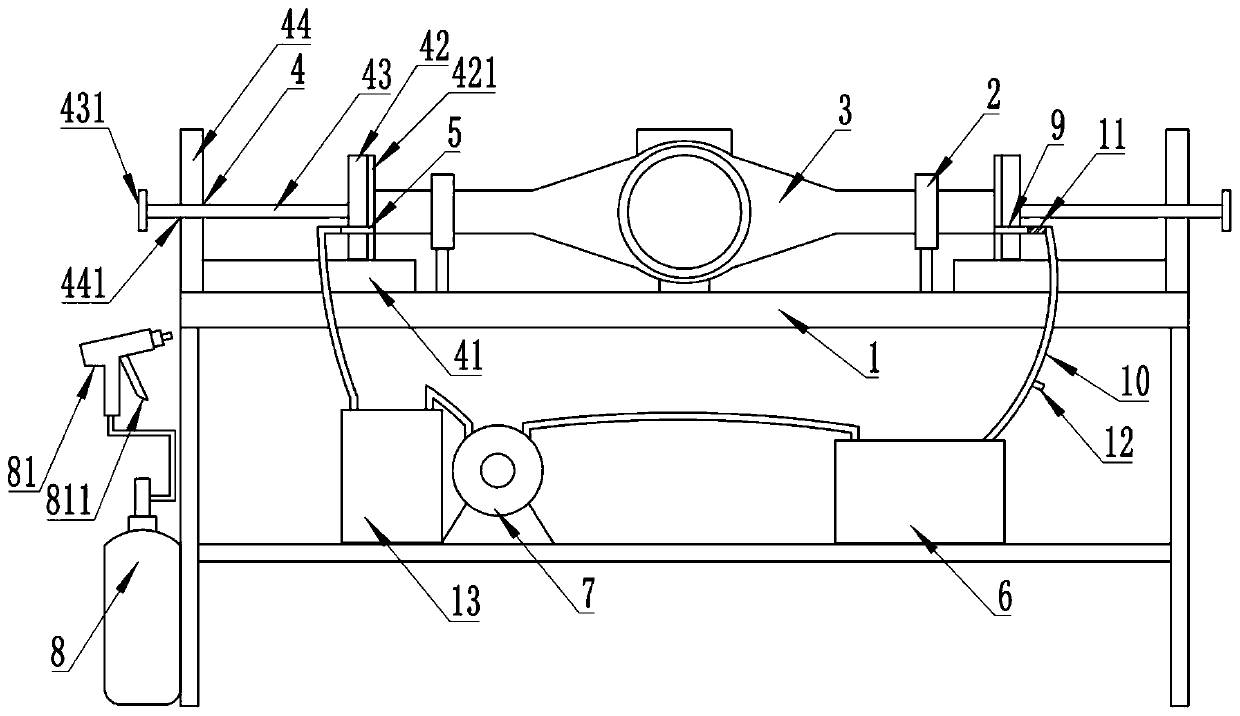

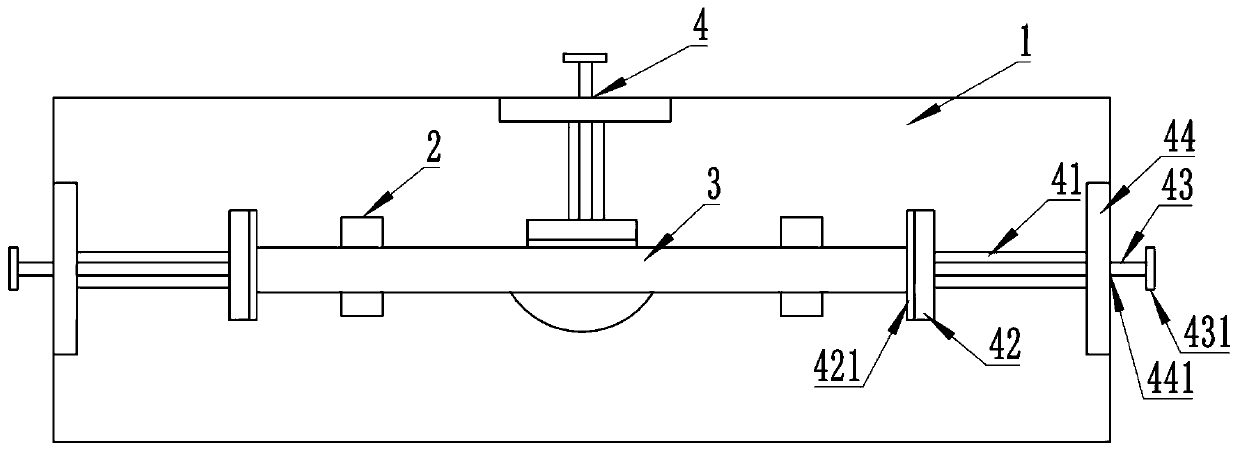

[0026] A leak detection device for the weld of the axle housing, such as Figure 1 to Figure 2 As shown, the workbench 1 is included. The workbench 1 is fixed with a support 2 for supporting the axle housing 3, and three sets of sealing devices 4 are provided. The sealing devices 4 are distributed on the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com