Silk fabric softening finishing agent and preparation method thereof

A fabric softening and finishing agent technology, applied in the field of textiles, can solve the problems of reduced elasticity and poor wrinkle resistance, and achieve the effect of maintaining softness, good wet elasticity and wrinkle resistance, and improving wet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

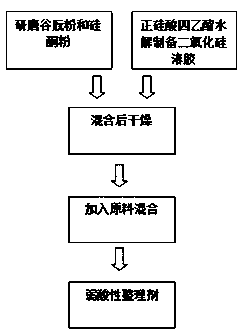

Method used

Image

Examples

Embodiment 1

[0038] (1) Grinding gluten powder and silicone powder KJ-B01 to micron level to obtain micron level gluten powder and micron level silicone powder;

[0039] (2) Add 75kg of tetraethyl orthosilicate, 4kg of ammonia water, and 12kg of ethanol into 150kg of water and mix evenly, then heat to hydrolyze tetraethyl orthosilicate at 55°C for 1.5 hours to obtain silica sol;

[0040](3) Add 20kg of micron-grade gluten powder to 55kg of silica sol, disperse evenly, and then use a spray dryer to dry to obtain compound gluten powder;

[0041] (4) Mix and disperse 55kg compound gluten powder and 0.8kg micron silicone powder KJ-B01 evenly to obtain a compound of compound gluten powder and silicone powder, then mix 15kg compound gluten powder and silicone powder KJ-B01 The compound of B01 is mixed with 8kg chitosan, 20kg water-based polyurethane, 150kg water and 4kg citric acid and dispersed evenly to obtain a weakly acidic silk fabric softening and finishing agent.

Embodiment 2

[0043] (1) Grinding gluten powder and silicone powder KJ-B01 to micron level to obtain micron level gluten powder and micron level silicone powder;

[0044] (2) Add 60kg of tetraethyl orthosilicate, 3.5kg of ammonia water, and 8kg of ethanol into 180kg of water and mix evenly, then heat to hydrolyze tetraethyl orthosilicate at 52°C for 2 hours to obtain silica sol;

[0045] (3) Add 18kg of micron-grade gluten powder to 58kg of silica sol, disperse evenly, and then use a spray dryer to dry to obtain compound gluten powder;

[0046] (4) Mix and disperse 52kg compound gluten powder and 0.6kg micron silicone powder KJ-B01 evenly to obtain a compound of compound gluten powder and silicone powder, then mix 15kg compound gluten powder and silicone powder KJ-B01 The composite of B01 is mixed with 6kg of chitosan, 18kg of water-based polyurethane, 180kg of water and 335kg of citric acid and dispersed evenly to obtain a weakly acidic silk fabric softening and finishing agent.

Embodiment 3

[0048] (1) Grinding gluten powder and silicone powder KJ-B01 to micron level to obtain micron level gluten powder and micron level silicone powder;

[0049] (2) Add 90kg of tetraethyl orthosilicate, 4.5kg of ammonia water, and 17kg of ethanol into 120kg of water and mix evenly, then heat to hydrolyze tetraethyl orthosilicate at 58°C for 1 hour to obtain silica sol;

[0050] (3) Add 22kg of micron-grade gluten powder to 52kg of silica sol, disperse evenly, and then use a spray dryer to dry to obtain compound gluten powder;

[0051] (4) Mix and disperse 58kg compound gluten powder and 0.8kg micron silicone powder KJ-B01 evenly to obtain a composite of compound gluten powder and silicone powder, then mix 15kg compound gluten powder and silicone powder KJ-B01 The compound of B01 is mixed with 8kg chitosan, 22kg water-based polyurethane, 130kg water and 4.5kg citric acid and dispersed uniformly to obtain a weakly acidic silk fabric softening and finishing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com