Advancing mechanism of tunnel track detection robot

A technology for track detection and travel mechanism, which is applied to the shape measuring instrument of railway vehicles, transmission devices driven by electric motors, railway inspection vehicles, etc., to achieve the effects of reducing weight, simplifying equipment, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

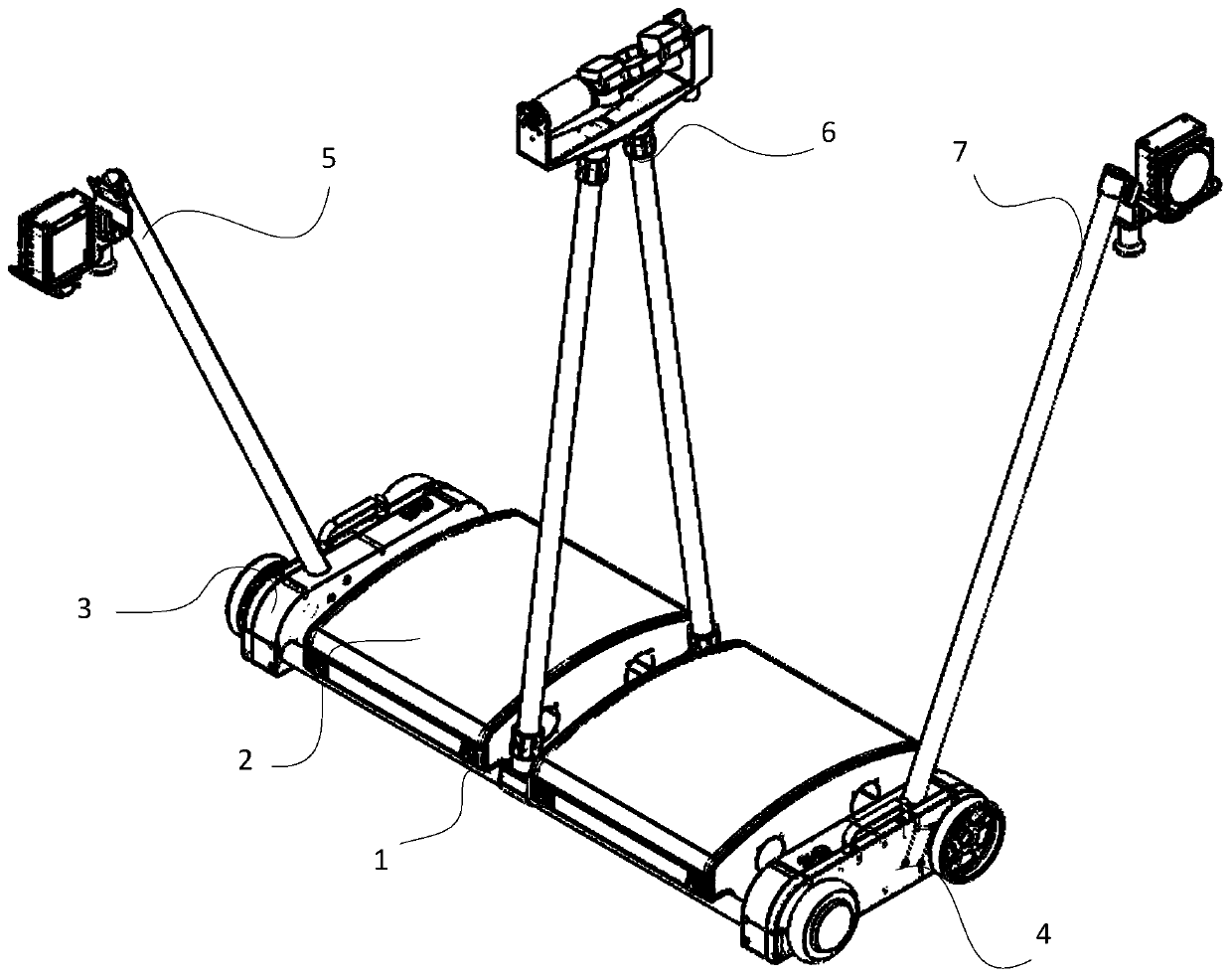

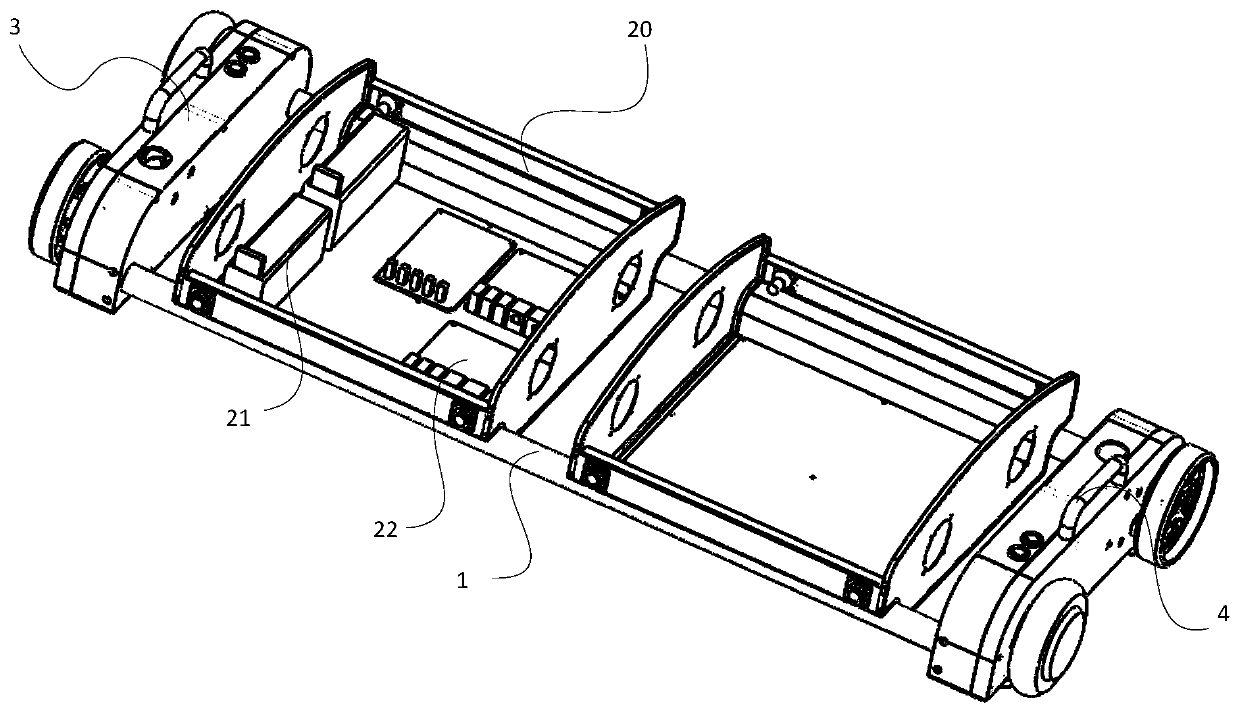

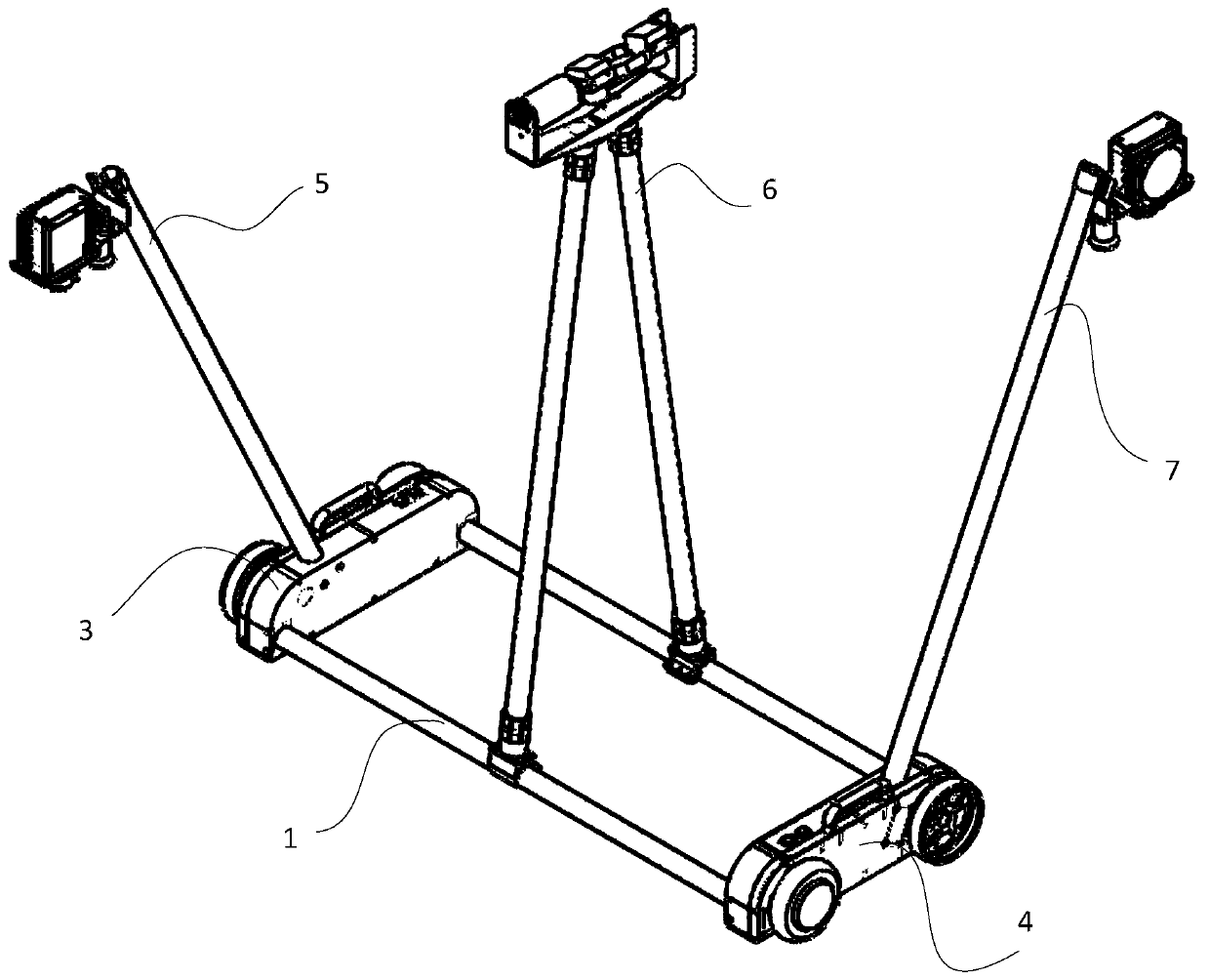

[0030] like Figure 1 to Figure 8 As shown, this embodiment provides a tunnel track detection robot, which travels (forward or backward) along the track direction. It should be noted that the serial numbers such as "first" and "second" in this embodiment are only used to distinguish similar components, and should not be understood as specific limitations on the scope of protection. In addition, the directional terms such as "bottom", "top", "surrounding edge", and "central" in this embodiment are explained based on the drawings; not only that, the circuit board of this embodiment is purchased, and Its control method is an existing conventional technology, so it will not be repeated here.

[0031] In this embodiment, the tunnel track inspection robot includes a vehicle frame 1, a first drive mechanism 3 and a second drive mechanism that are fixed to both ends of the vehicle frame 1 in one-to-one correspondence and slide with the track limit, and have the same structure. 4. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com