A printing machine ink cartridge supporting processing method

A treatment method and printing machine technology, applied in the field of cleaning, can solve the problems of non-recycling of sewage, low cleaning efficiency, high labor intensity, etc., and achieve the effects of facilitating cleaning operations, improving utilization rate, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

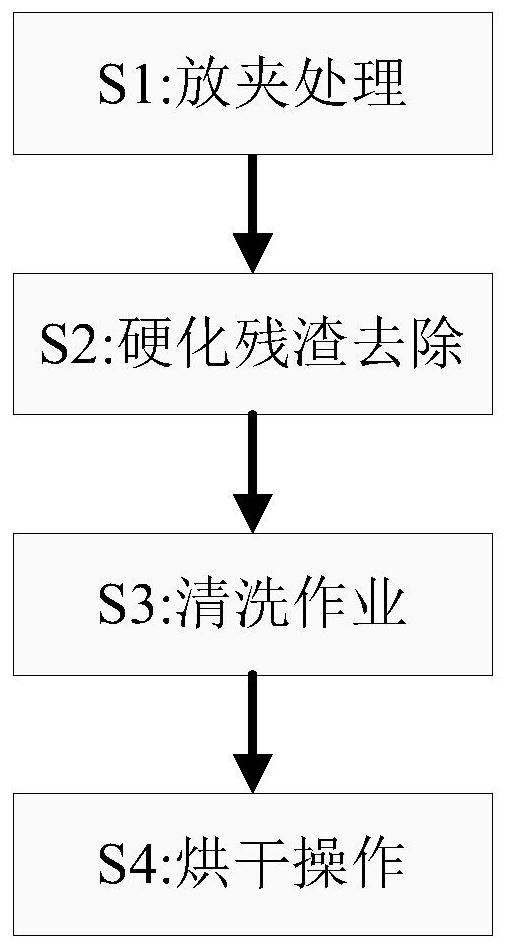

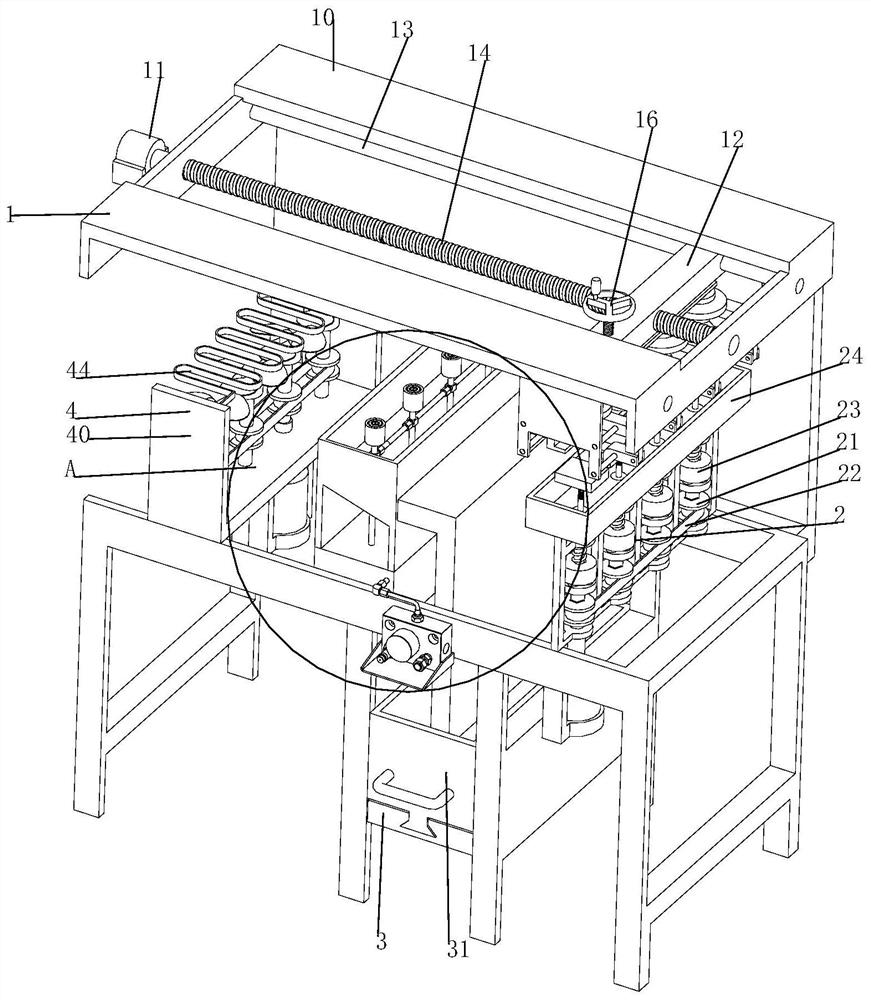

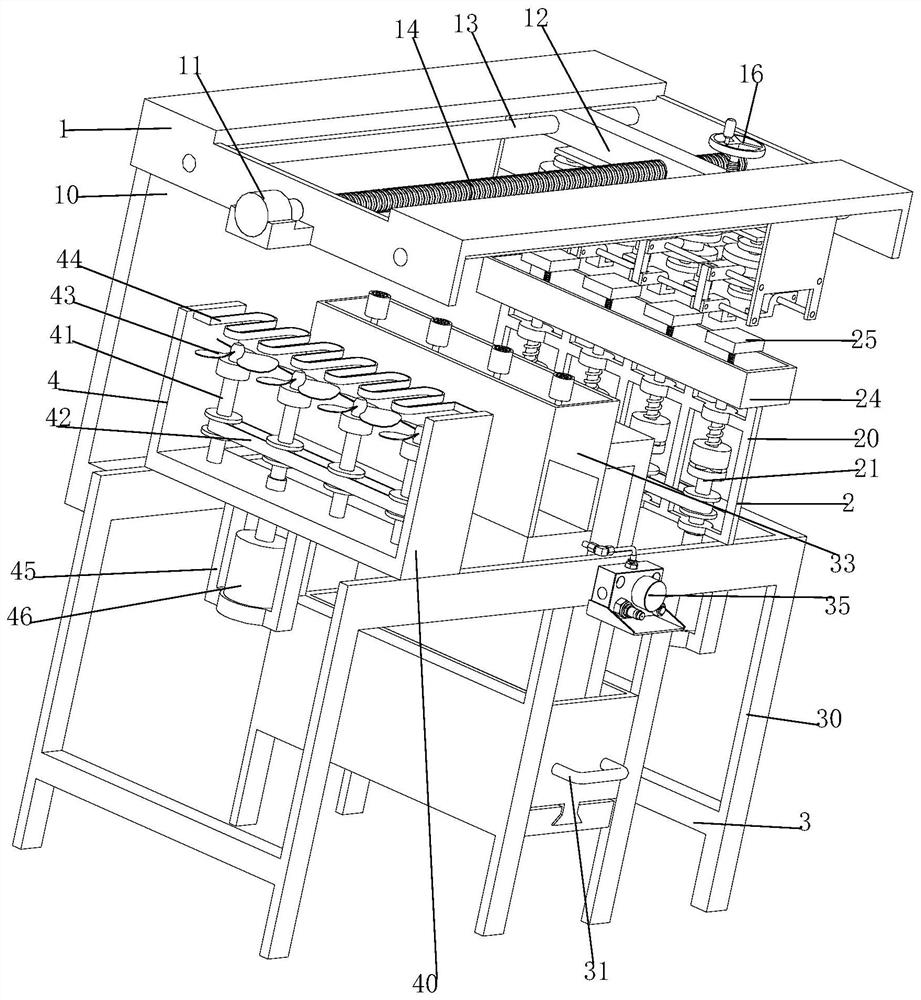

[0034] like Figure 1 to Figure 8 As shown, a printing machine ink cartridge supporting processing method, which uses a kind of ink cartridge cleaning equipment, the ink cartridge cleaning equipment includes a hoisting mechanism 1, a shedding mechanism 2, a cleaning mechanism 3 and a drying mechanism 4, using the above ink cartridge cleaning equipment to clean the ink cartridges The specific method of cleaning and drying is as follows:

[0035] S1. Clamping process: perform multi-station clamping through the clamping unit 18, and then control the moving distance of the lead screw 14 to drive the sliding frame 12 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com