Grinding device for metal surface treatment

A technology for metal surface treatment and grinding mechanism, which is applied to grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc. The effect of simple structure and good fixed function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

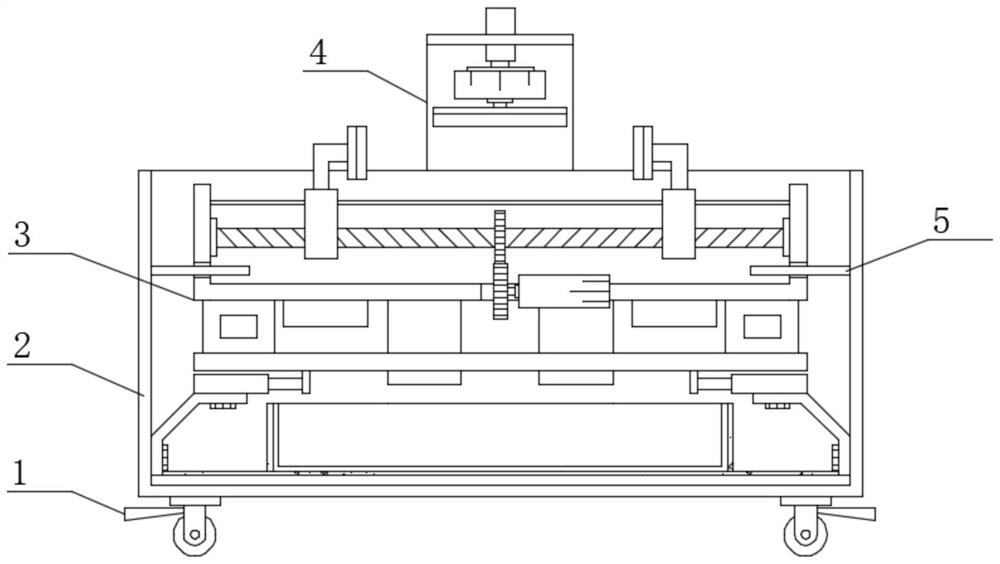

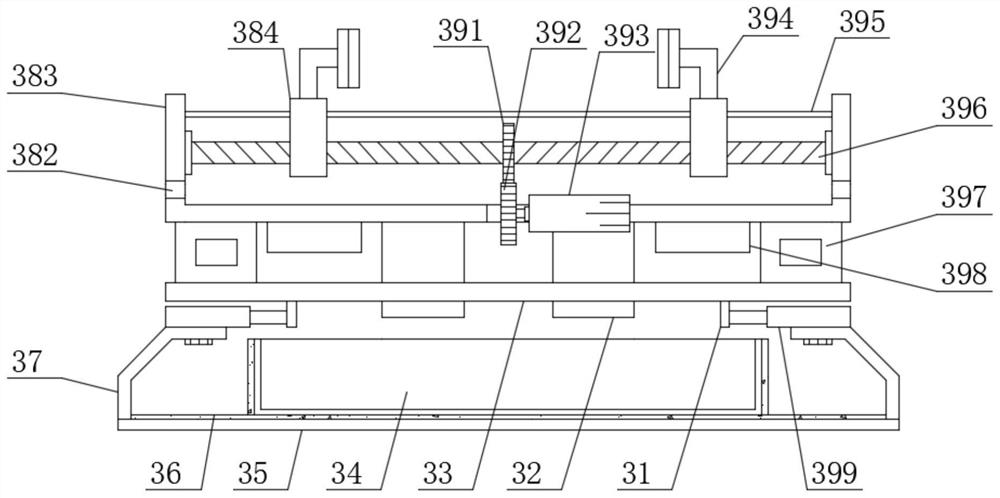

[0023] see Figure 1-Figure 3 , the present invention provides a technical solution: a metal surface treatment grinding device, including a housing 2, the top of the housing 2 is provided with a grinding mechanism 4, the use of the grinding mechanism 4 is the prior art, the bottom of the grinding mechanism 4 It is fixedly connected with the housing 2 by welding. The interior of the housing 2 is provided with a fixing mechanism 3. The fixing mechanism 3 includes a second support plate 35. A first support plate 33 is arranged above the second support plate 35. The second support plate The two ends of the upper surface of 35 are provided with a support member 37, and the top of the support member 37 is provided with a horizontally telescopic electric telescopic rod 399; Two limit plates 31, a limit base 383 is arranged above the first support plate 33, and rubber plates 397 corresponding to the limit base 383 are provided on both ends of the upper surface of the first support pla...

Embodiment 2

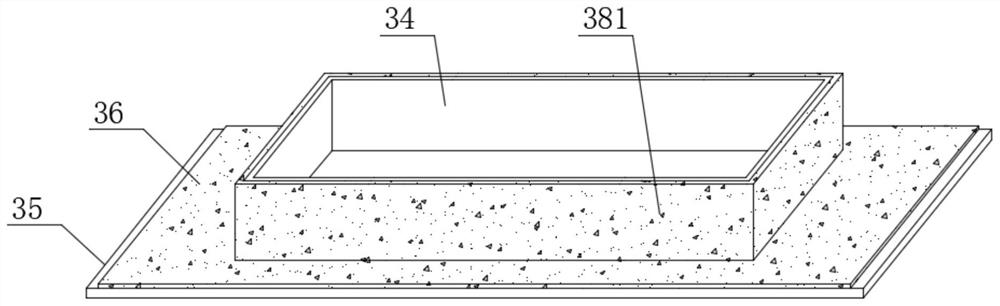

[0032] On the basis of Embodiment 1, in order to enrich the functions of the grinding device, in this embodiment, preferably, a collection box 34 is movable above the second support plate 35, and the outer surface of the collection box 34 is covered with a second The sound-absorbing cotton 381, the second sound-absorbing cotton 381 and the collection box 34 are bonded and connected by glue. When in use, the debris generated during grinding is collected through the collection box 34. The second sound-absorbing cotton 381 plays a role in reducing noise, so that the grinding device emits less noise;

[0033] In order to further enhance the noise reduction effect of the grinding device, in this embodiment, preferably, the upper surface of the second support plate 35 is provided with a first sound-absorbing cotton 36 corresponding to the collection box 34, and the first sound-absorbing cotton 36 and the second support The plates 35 are connected by glue bonding;

[0034] In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com