Processing technology of leather bag oil edge

A processing technology and oil edge technology, which is applied in the field of leather-wrapped oil edge processing technology, can solve the problems of low oil edge tensile strength and elongation at break, oil edge easy to fall off, oil edge easy to break, etc. Strength and elongation at break, not easy to break, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

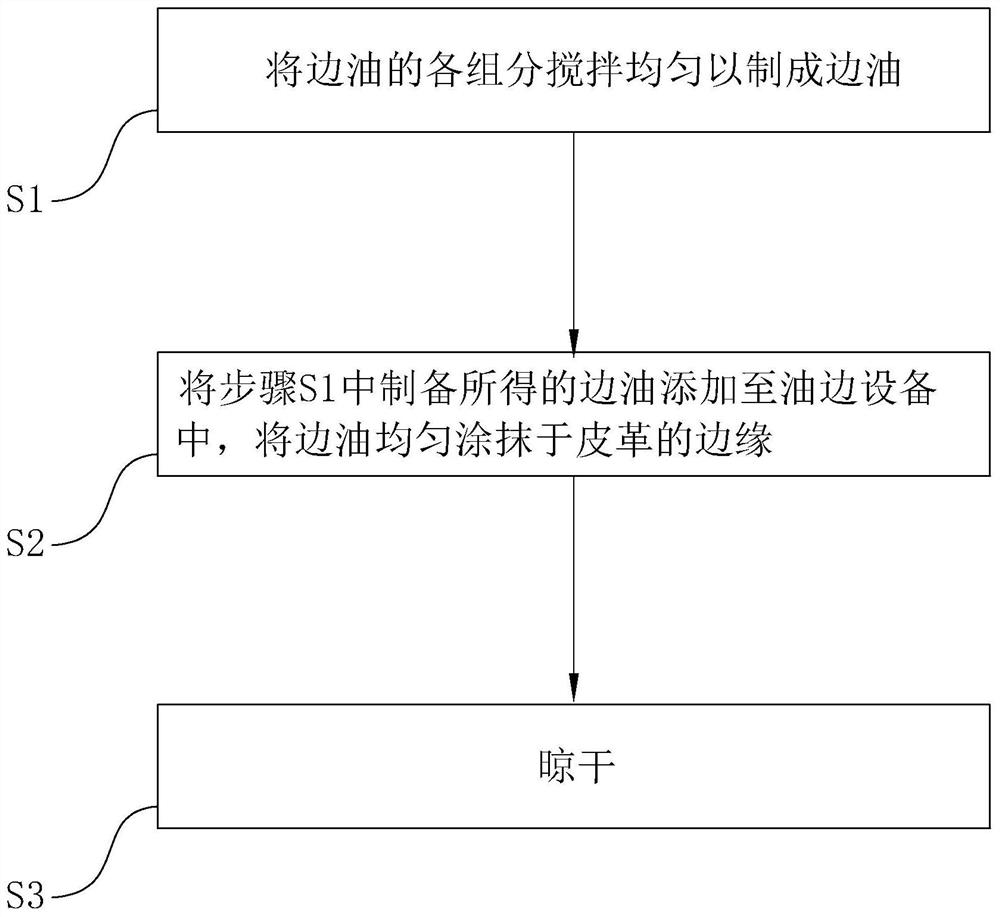

[0075] A processing technology for leather bag oil edge, comprising the following steps:

[0076] S1, prepare edge oil, specifically as follows:

[0077] In a 150L stirred tank, under normal temperature, add 17kg of polyurethane and 80kg of water, stir at a speed of 300r / min, add 13kg of acrylic acid, 10kg of pigment, 5kg of ethanol, 5kg of thickener, 2kg of defoamer, N , N-two (hydroxyethyl) cocamide 1kg, flurbiprofen 1kg, hydroxypivalate neopentyl glycol ester 0.3kg, stir well, form edge oil.

[0078] S2. Apply edge oil, as follows:

[0079] The edge oil prepared in step S1 is added to the edge oiling machine, and the leather is slowly slid over the feeding roller of the oil edge machine, so that the edge oil is evenly applied to the edge of the leather.

[0080] S3, dry, specifically as follows:

[0081] Pick up the leather evenly coated with edge oil with clips and let it dry to obtain the oiled edge of the leather bag.

[0082] In this embodiment, the thickener is car...

Embodiment 2

[0084] The difference with embodiment 1 is:

[0085] The consumption of each component that adds in the step S1 is as follows:

[0086] Polyurethane 16kg; Water 87.5kg; Acrylic acid 11.5kg; Pigment 7.5kg; Ethanol 4kg; Thickener 4kg; Defoamer 1.5kg; kg; Neopentyl glycol hydroxypivalate 0.2kg.

Embodiment 3

[0088] The difference with embodiment 1 is:

[0089] The consumption of each component that adds in the step S1 is as follows:

[0090] Polyurethane 15kg; Water 95kg; Acrylic acid 10kg; Pigment 5kg; Ethanol 3kg; Thickener 3kg; Neopentyl glycol valerate 0.1kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com