Outdoor multi-hybrid self-cleaning energy-saving luminous sand and preparation method thereof

A self-cleaning and multiple technology, which is applied in the field of multiple hybrid self-cleaning energy-saving luminous sand for outdoor use and its preparation, can solve the problems of easy adsorption of dust, affecting the luminous and reflective effects of materials, and lack of energy-saving performance, so as to improve the mechanical strength. , the effect of bright colors and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

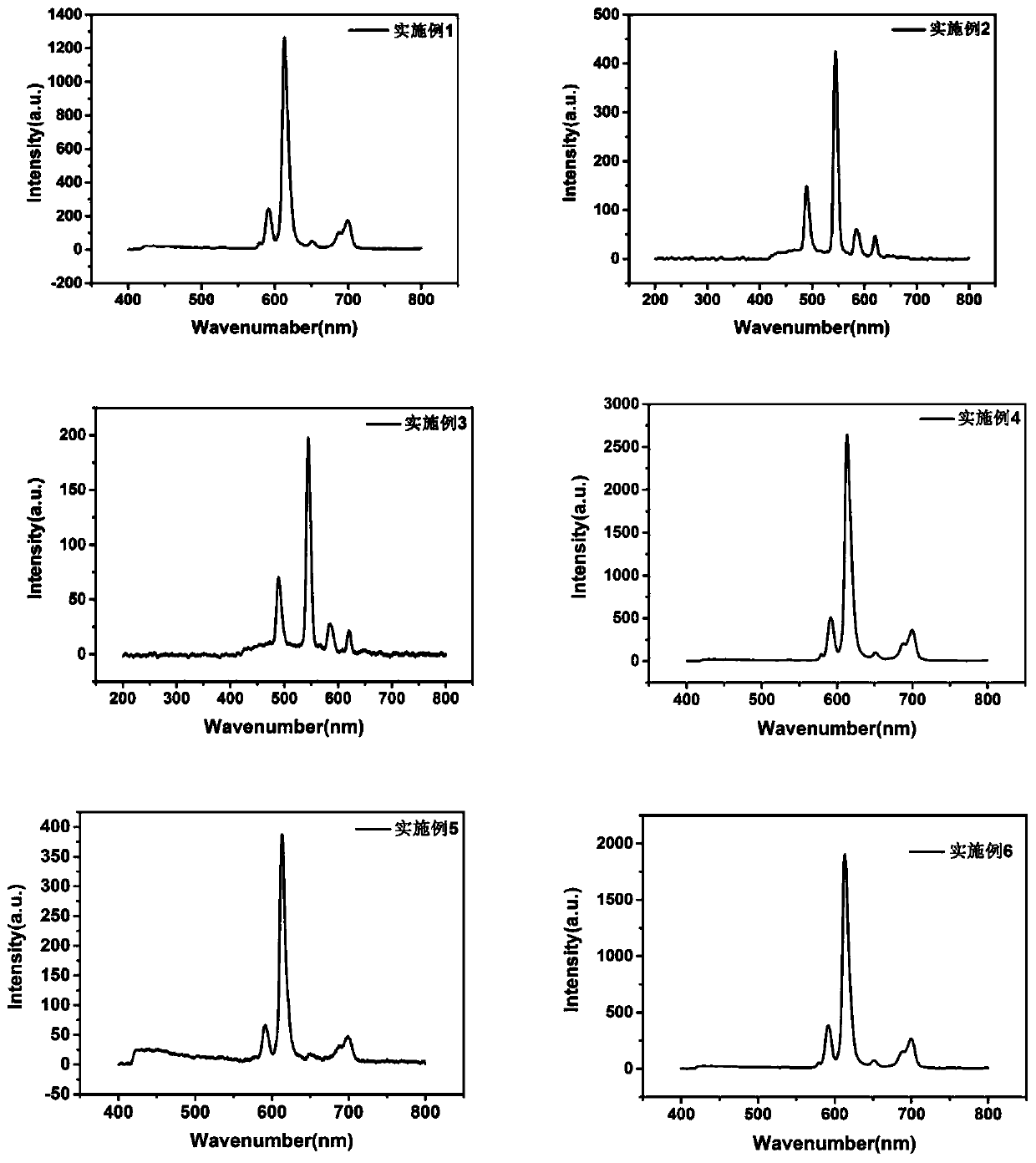

Embodiment 1

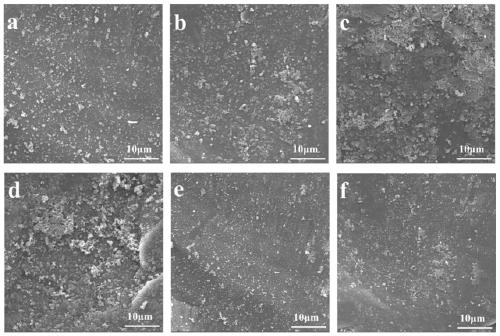

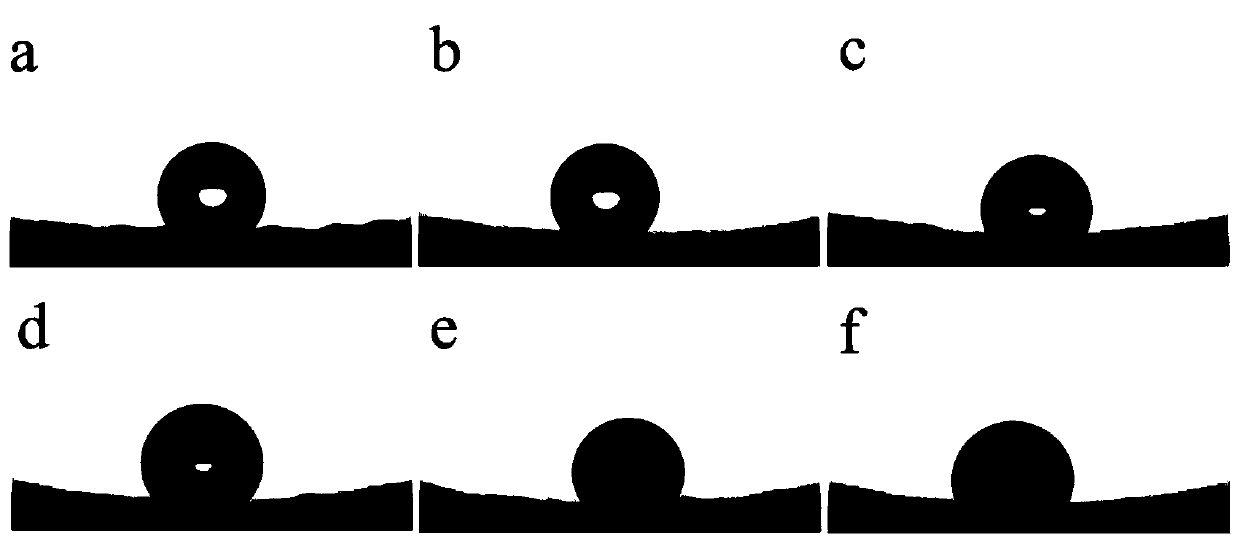

[0029] A method for preparing multiple hybrid high-efficiency, energy-saving and high-efficiency red light sand, comprising the following steps:

[0030] (1) The surface of the quartz sand is cleaned with hydrochloric acid, sodium hydroxide ethanol solution and deionized water in sequence until the surface is free of oil stains or inorganic contamination, and then dried.

[0031] (2) Add 5g of quartz sand with a particle size of 100-200 microns to 100ml of ethanol, then add 50ml of 0.14M cetyltrimethylammonium bromide solution, stir well, and control the reaction temperature at 25°C. Adjust the pH of the solution to 12 with ammonia water at a concentration of 1M, add 10ml tetraethyl orthosilicate dropwise to the above solution, fully react for 12 hours, fully wash with deionized water, and dry to obtain the coated micro-nano particle structure. quartz sand.

[0032] (3) 0.02mol of EuCl 3 Solution, 0.06mol organic ligand tta and 0.02mol organic small molecule ligand phen were...

Embodiment 2

[0035] A method for preparing multiple hybrid high-efficiency, energy-saving, and high-efficiency green light-emitting sands. Include the following steps:

[0036] (1) The surface of the sea sand is cleaned with hydrochloric acid, sodium hydroxide ethanol solution and deionized water in sequence until the surface is free of oil stains or inorganic pollution, and then dried.

[0037](2) Add 10g of sea sand with a particle size of 100-400 microns to 200ml of methanol, then add 50ml of 0.28M cetyltrimethylammonium bromide solution, stir well, and control the reaction temperature at 20°C. 5M concentration of sodium hydroxide to adjust the pH of the solution to 12, add 20ml tetraethyl orthosilicate dropwise to the above solution, fully react for 18 hours, fully wash with deionized water, and dry to obtain coated micro-nano particles Structural aggregate sand.

[0038] (3) 0.06mol of TbCl 3 Solution, 0.18 mol organic ligand acac and 0.06 mol organic small molecule ligand phen wer...

Embodiment 3

[0041] A method for preparing multiple hybrid high-efficiency, energy-saving, and high-efficiency green light-emitting sands. Include the following steps:

[0042] (1) The surface of the desert sand is cleaned with hydrochloric acid, sodium hydroxide ethanol solution and deionized water in sequence until the surface is free of oil stains or inorganic pollution, and then dried.

[0043] (2) Add 10g of desert sand with a particle size of 200-400 microns to 200ml of methanol, then add 50ml of 0.28M polyvinylpyrrolidone solution, stir well, and control the reaction temperature at 30°C. Adjust the pH to 13, add 20ml of tetraethyl orthosilicate dropwise to the above solution, fully react for 20 hours, fully wash with deionized water, and dry to obtain desert sand coated with micro-nano particle structure.

[0044] (3) 0.06mol of TbCl 3 solution, 0.18 mol of organic ligand acac and 0.06 mol of organic small molecule ligand Bipy were dissolved in 1L of methanol solution, stirred at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com