Process for neutralizing and rectifying high-hydrochloric-acid n-butyl alcohol wastewater

A technology of n-butanol hydrochloride and n-butanol, which is applied in the field of water treatment, can solve the problems of unsatisfactory aerobic treatment effect, high operating cost, poor biochemical properties, etc., and achieve the effect of stable treatment effect, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

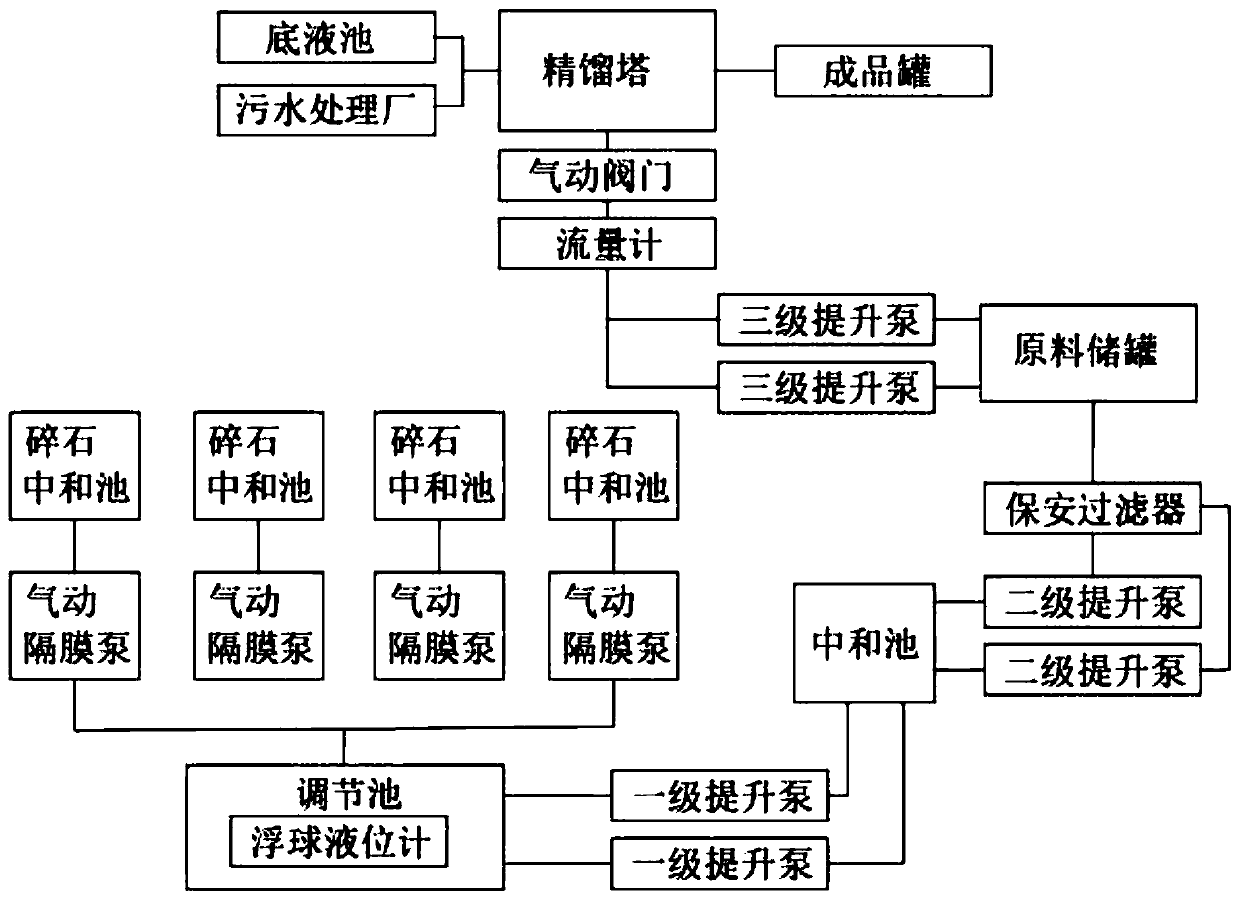

[0018] see figure 1 , a process for neutralizing and rectifying high hydrochloric acid n-butanol wastewater, comprising the following steps:

[0019] (1) Since the high hydrochloric acid n-butanol wastewater is quantitatively discharged in batches, four gravel neutralization tanks are set up to receive and process different batches of wastewater at different times, and each gravel neutralization tank is equipped with a pneumatic diaphragm The pump is used for waste water circulation to contact stones and supply water to the regulating pool; add high-purity calcium stone to the stone neutralization pool, and the calcium carbonate in the calcium stone will neutralize the hydrochloric acid in the wastewater during the process of wastewater passing through the calcium stone;

[0020] (2) The adjustment tank is equipped with two first-stage lift pumps (pneumatic diaphragm pumps are selected), and the high start and low stop are controlled by the float level gauge to supply water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com