Rotary-table fixture

A tooling fixture and turntable technology, which is applied in the field of tooling and fixtures, can solve the problems of losing the wide application of turntable fixtures and the inactivity of the fixtures, and achieves the effect of saving rotating force and reducing operating procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

[0024] The turntable tooling fixture of the present invention is suitable for automatic processing equipment, robot equipment, etc., and the turntable tooling fixture provided by the present invention is described in detail below:

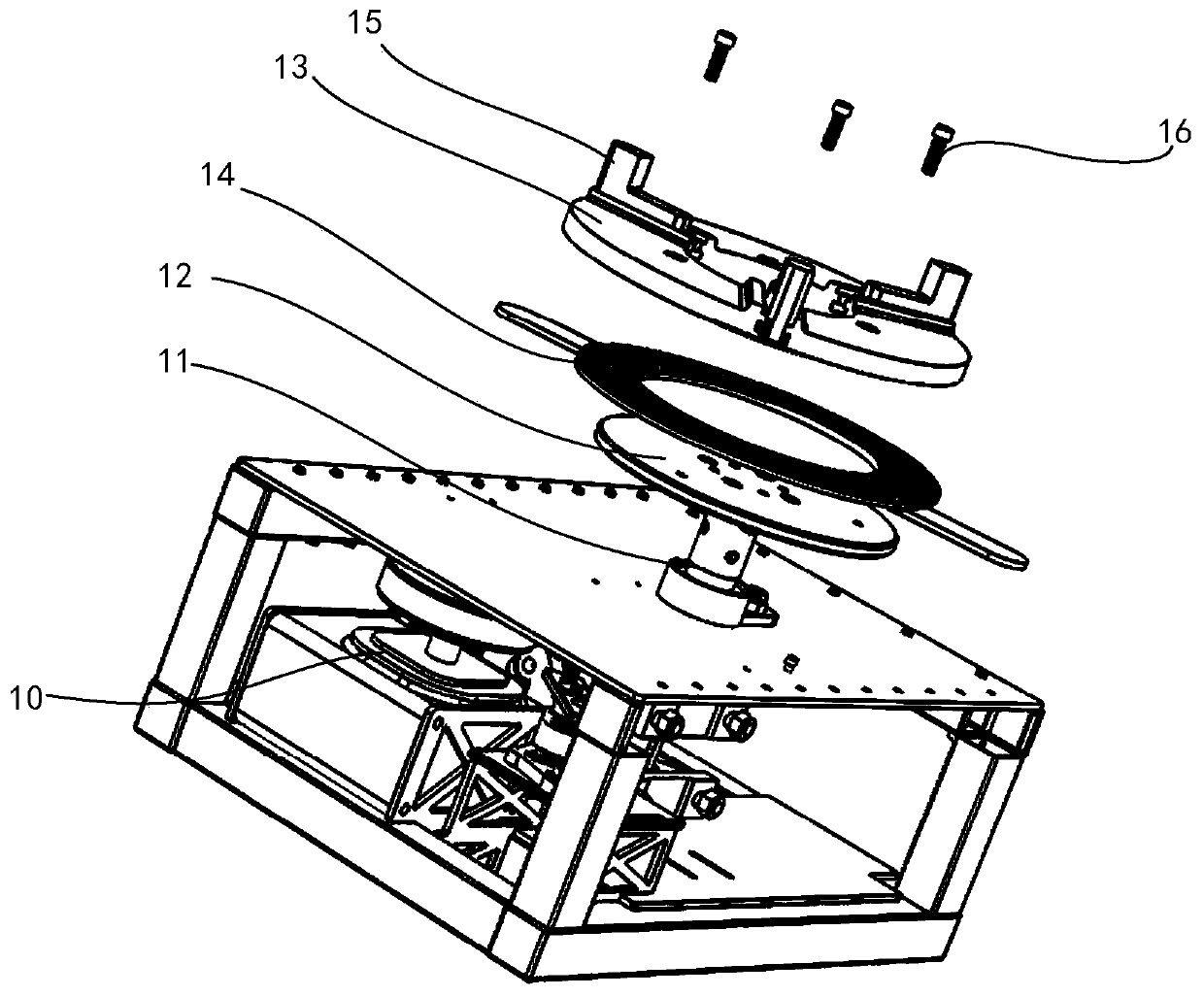

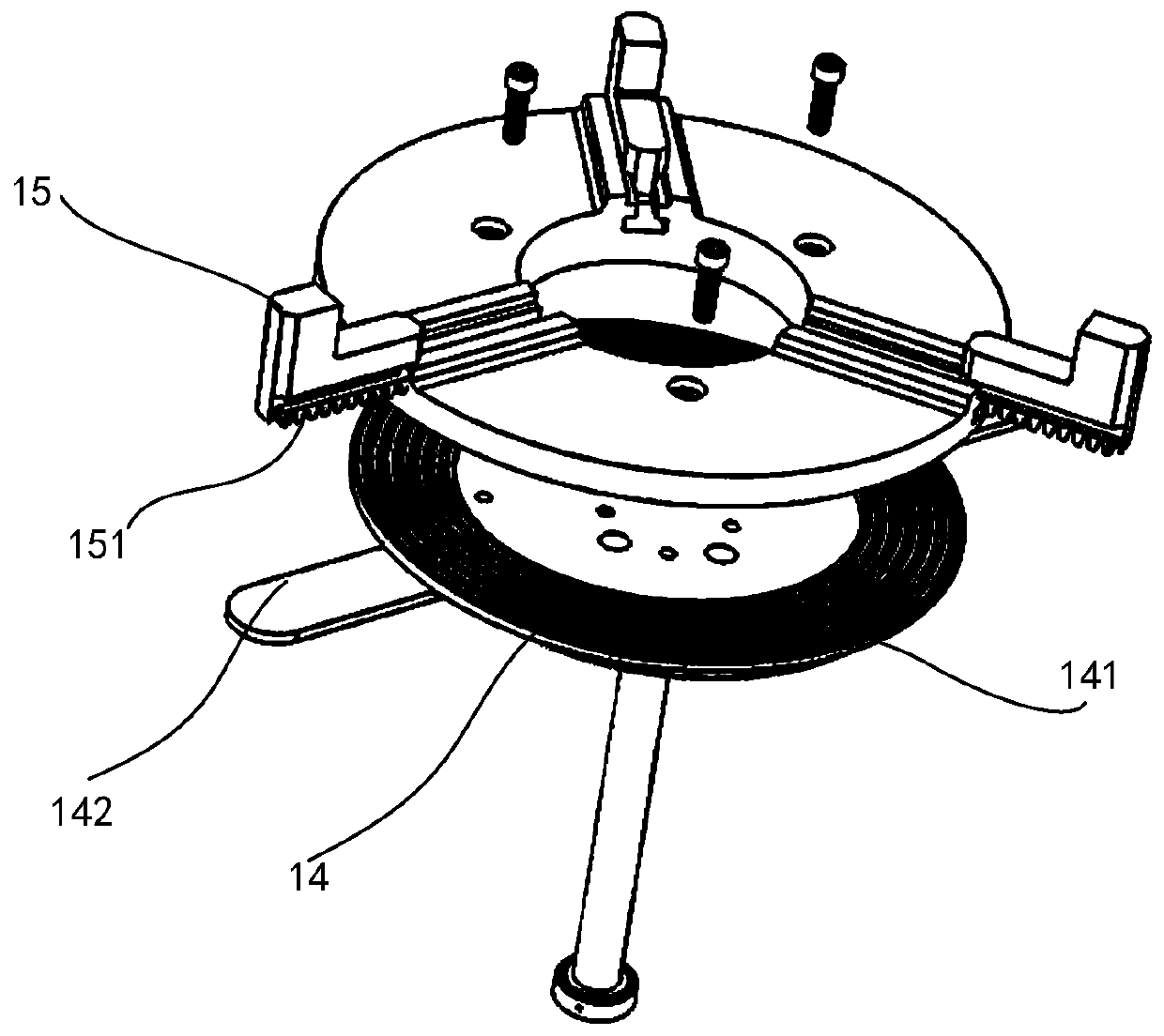

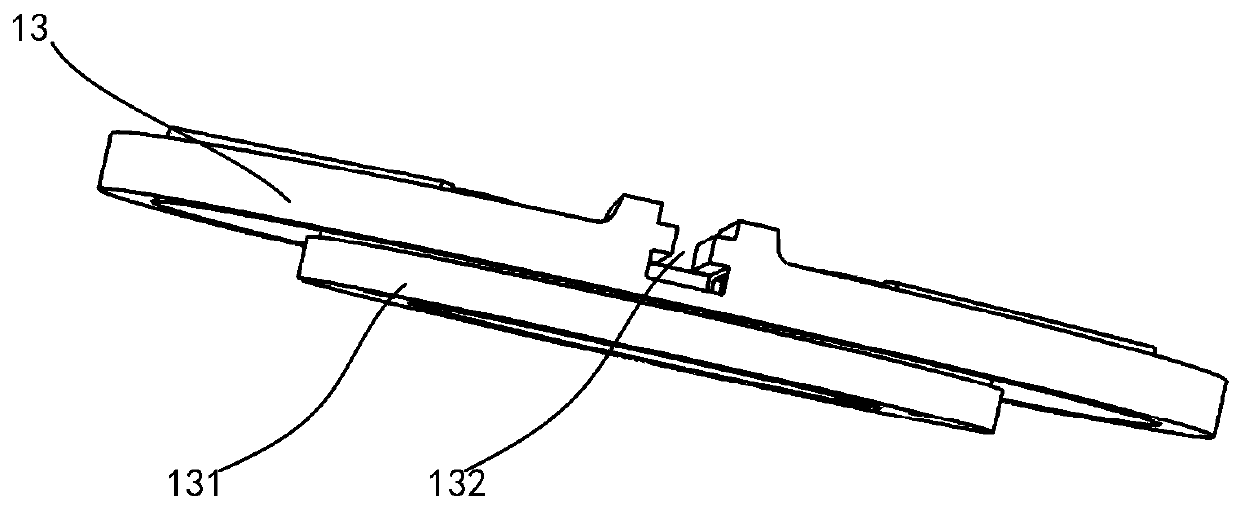

[0025] Figure 1-Figure 3 Shown is a schematic structural diagram of the turntable tooling fixture, which includes:

[0026] The driving motor 10 transmits its driving force to the rotating drive shaft 11, wherein the power of the driving motor 10 can also be transmitted through a belt.

[0027] The first turntable 12 is fixedly connected to the rotary drive shaft 11 and can rotate together with the rotary drive shaft 11. The first turntable 12 plays the role o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com