Efficient intelligent grain removing and sorting machine

A cleaning machine and grain technology, applied in sorting and other directions, can solve the problems of unstable quality of processed products, complicated equipment operation, large processing loss, etc., and achieve the effect of reducing operating costs, reducing processing equipment, and reducing losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

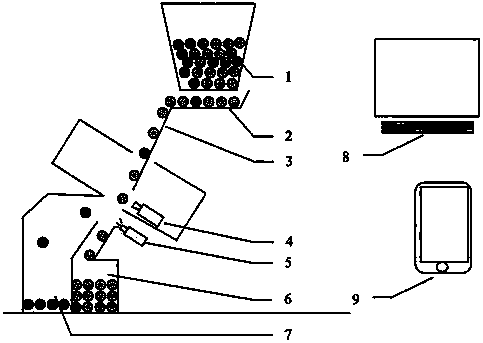

[0015] The storage bin 1 is the storage bin for grain and seeds ("materials"), the "materials" fall to the feeder 2, and the feeder 2 evenly transports the "materials" to the identification channel 3, and the "materials" pass through the identification channel 3 evenly At this time, the camera 4 will continue to take pictures of the material images and transmit them to the computer system 8. The computer system 8 analyzes and judges the material images. If waste is found, it will send a signal to the pneumatic reject valve 5 to start the valve and use compressed air to remove the waste. The waste material is blown to the waste material storage bin 7; if no waste material is found, the grain and seeds will keep the flow direction and enter the good product grain storage bin.

[0016] When the material passes through the identification channel 3, a certain speed should be maintained to ensure that there is a distance between individual grains and seed particles, to ensure that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com