Low-salt raw wet manual fermented oil noodles and preparation method thereof

A salt-producing and manual technology, applied in the fields of food science, food preservation, food ingredients as taste improver, etc., can solve problems such as affecting quality, broken strips, etc., and achieve the effect of reducing salt consumption, oil absorption rate, and product quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

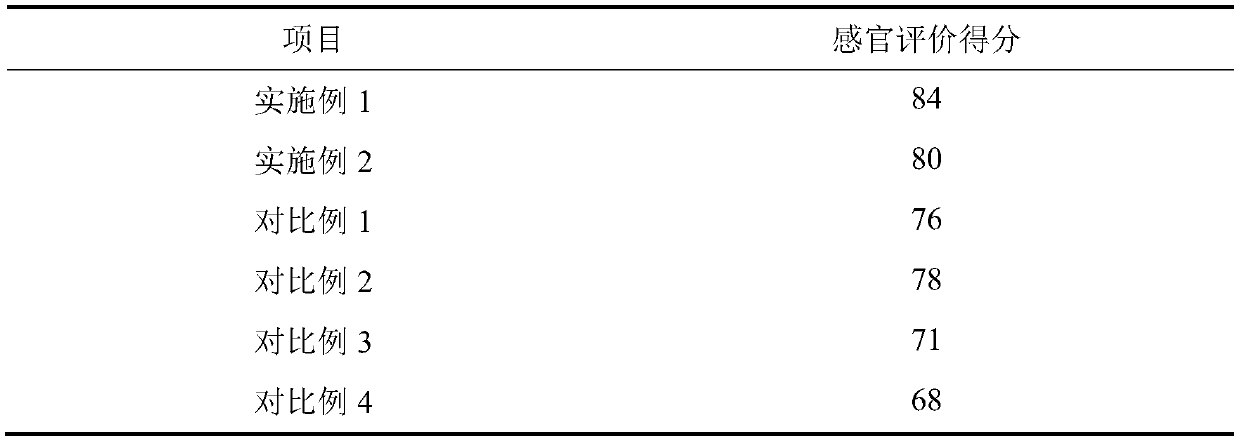

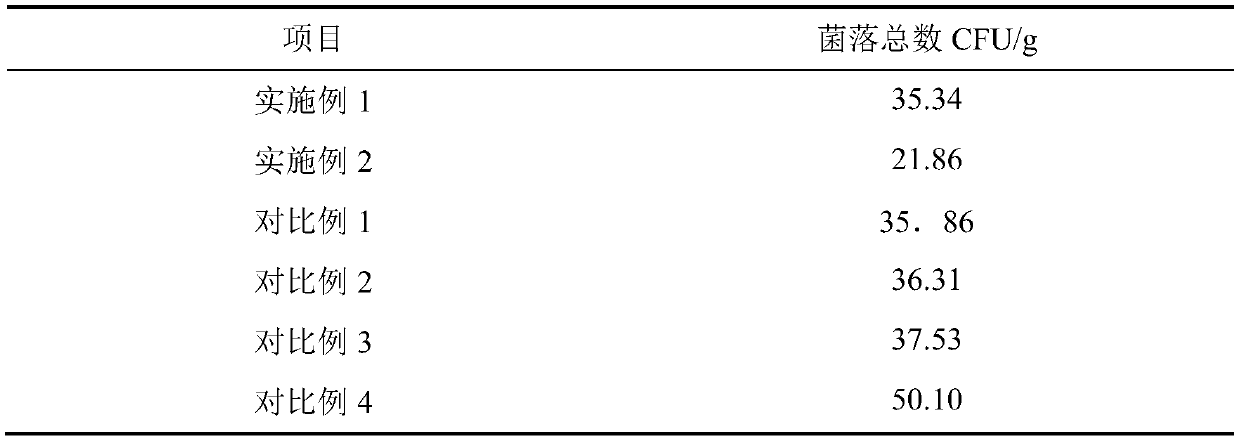

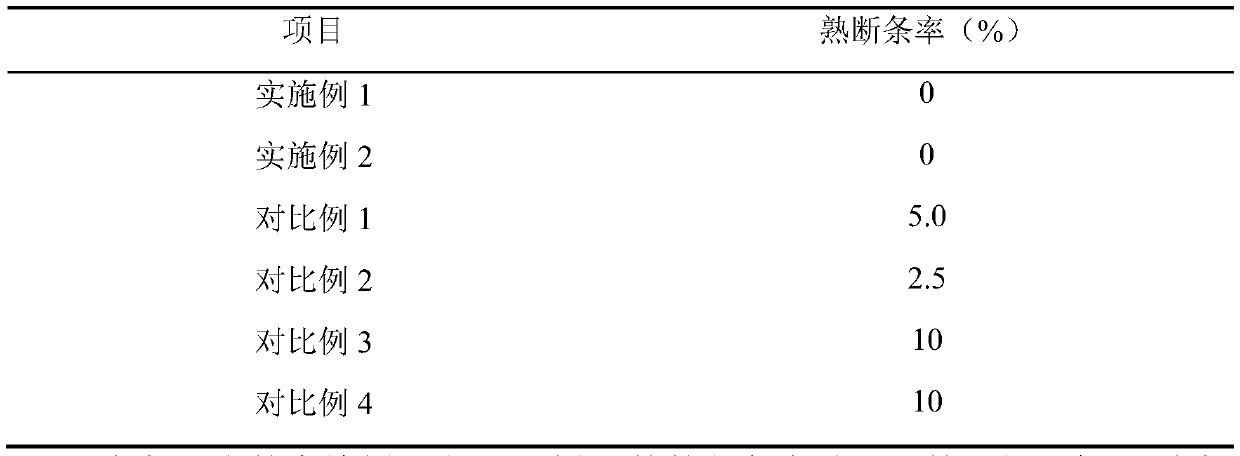

Examples

Embodiment 1

[0030] A method for preparing low-salt handmade raw wet fermented oil noodles, the steps are as follows:

[0031] Before making the low-salt raw wet manual fermented oil, use ultraviolet light to clean and disinfect the production environment and production equipment, and spray 75% alcohol to ensure that the production environment is clean and pollution-free, ventilated and dry, and the hands of production personnel are disinfected with 75% alcohol , The raw materials are also kept clean.

[0032] Prepare raw materials: 500g of high-gluten wheat flour, 100g of sweet potato flour, 200g of water, 50g of egg white, 5g of salt, and 1.5g of dry yeast.

[0033] Pre-gelatinization of sweet potato flour: steam sweet potato flour with water (60-80°C, 30min) to gelatinize the starch and cool it for later use;

[0034] In the sieving process, the flour raw materials (high-gluten wheat flour, salt, dry yeast) are screened through a 70-100 mesh sieve (70-100 mesh is reserved) to prevent f...

Embodiment 2

[0046] The difference with Example 1 is:

[0047] The dosage of raw materials is 500g of high-gluten wheat flour, 100g of sweet potato flour, 200g of water, 50g of egg white, 10g of salt, and 1.5g of dry yeast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com