Grating substitute, target calibration device and calibration method based on grating spectrometer

A calibration device and target point technology, which is applied in the field of optical experiments, can solve problems affecting imaging and measurement results, grating diffraction angle errors, and low aiming and positioning accuracy, and achieve high quality, improved accuracy, and improved quality and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

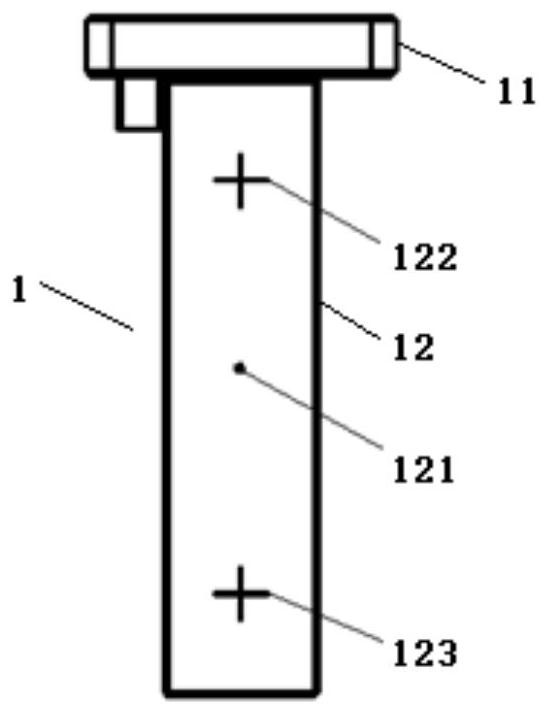

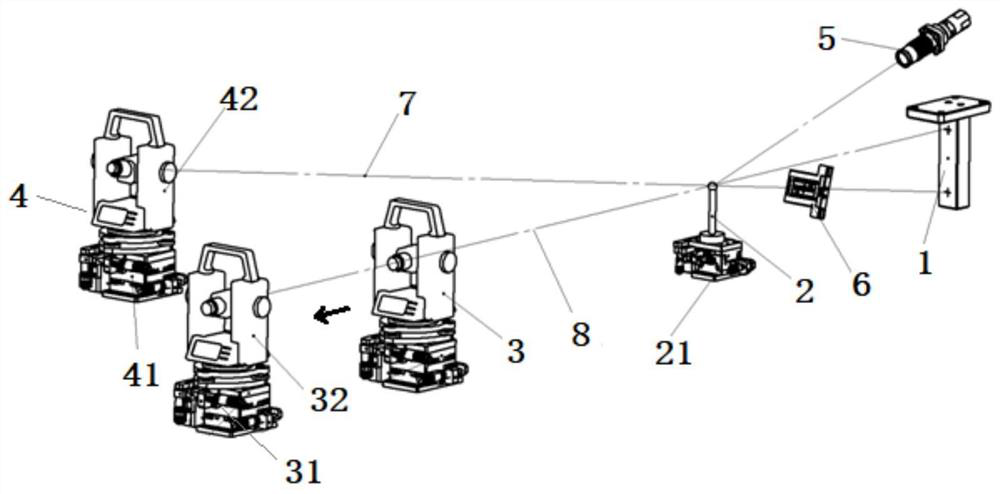

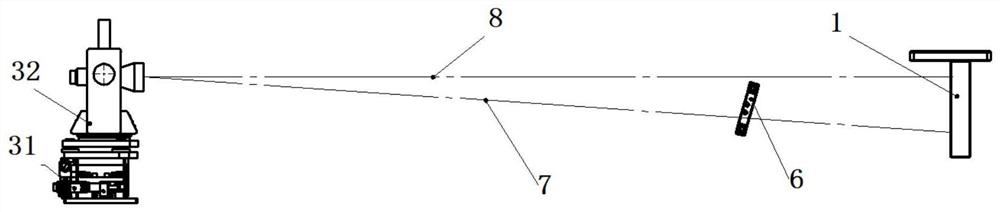

[0038] The present invention provides a grating replacement such as figure 1 As shown, the grating substitute 1 includes a horizontal mounting plate 11 and a vertical reference plate 12; the horizontal mounting plate 11 is vertically installed above the vertical reference plate 12; the positioning reference plane 121 of the vertical reference plate 12 is vertically There is an upper cross wire 122 and a lower cross wire 123; the vertical reference plate 12 is made of stainless steel; the positioning reference plane 121 is a polished mirror surface, which is convenient for the alignment of the first theodolite 32; the center distance between the upper cross wire 122 and the lower cross wire 123 Calculated according to the diffraction angle of the grating, the accuracy of the center distance between the upper reticle 122 and the lower reticle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com