Poking-groove liner tube node structure applied to on-site splicing of box-type support

A groove lining and node technology, applied in the direction of building structure, construction, etc., can solve the problems of no installation gap, difficult to fully penetrate the welding seam, difficult to fill the support, etc., to achieve easy welding, high welding quality reliability, Good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

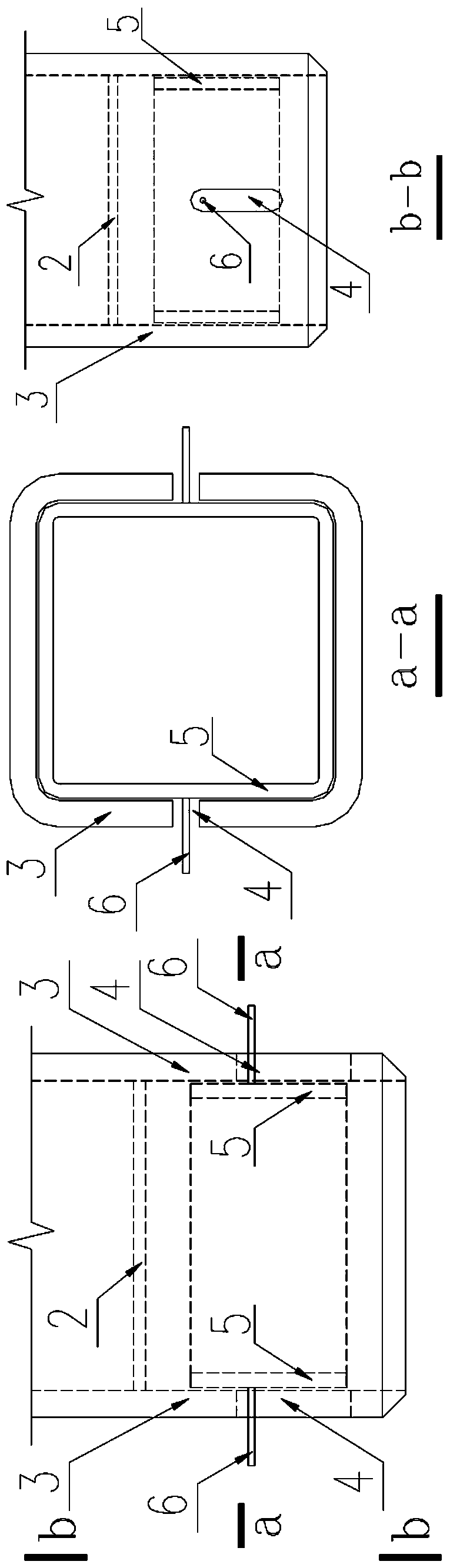

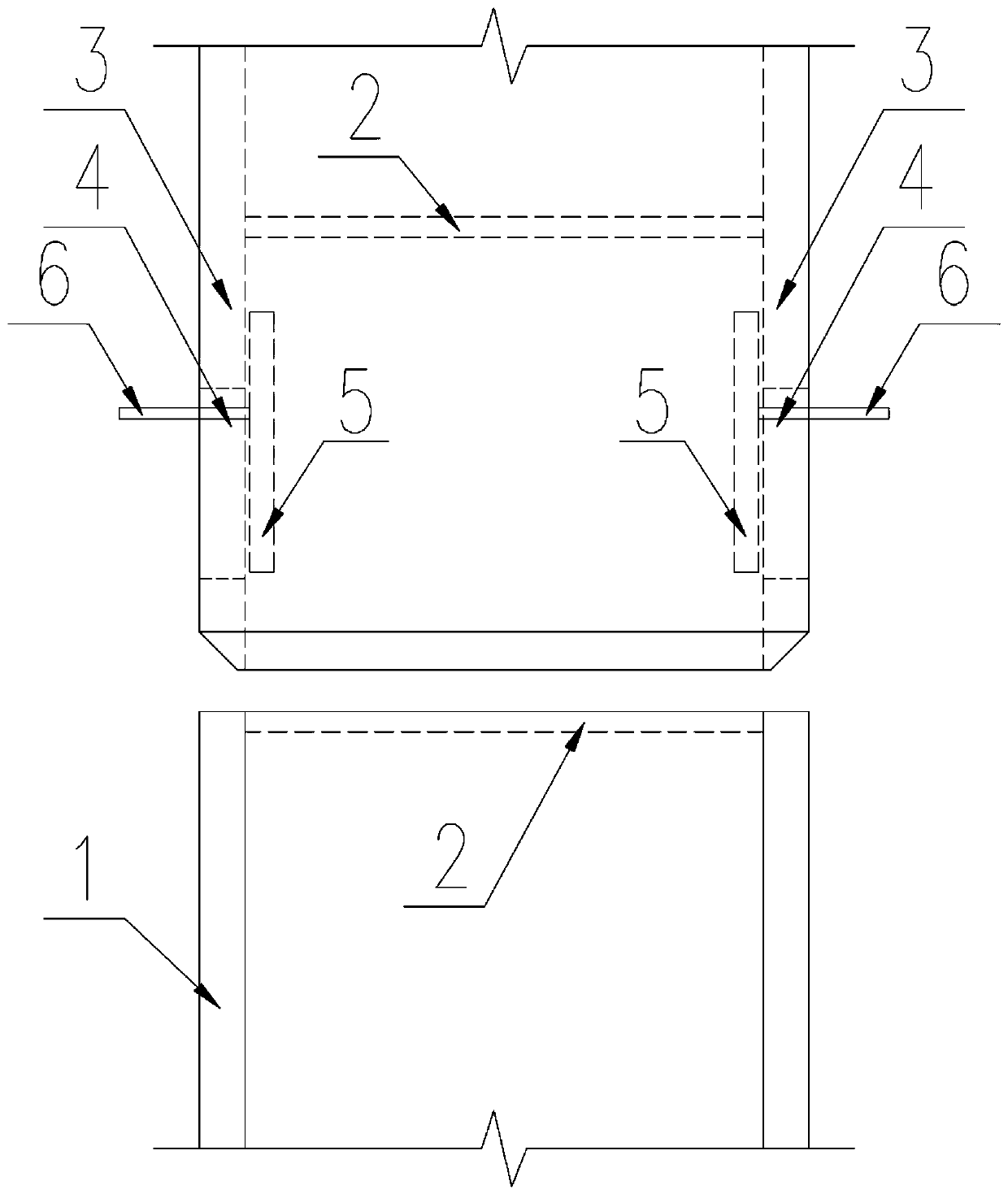

[0027] The embodiments of the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only used to explain the technical solutions of the present invention more clearly, and therefore are only used as examples, and cannot be used to limit the protection scope of the present invention.

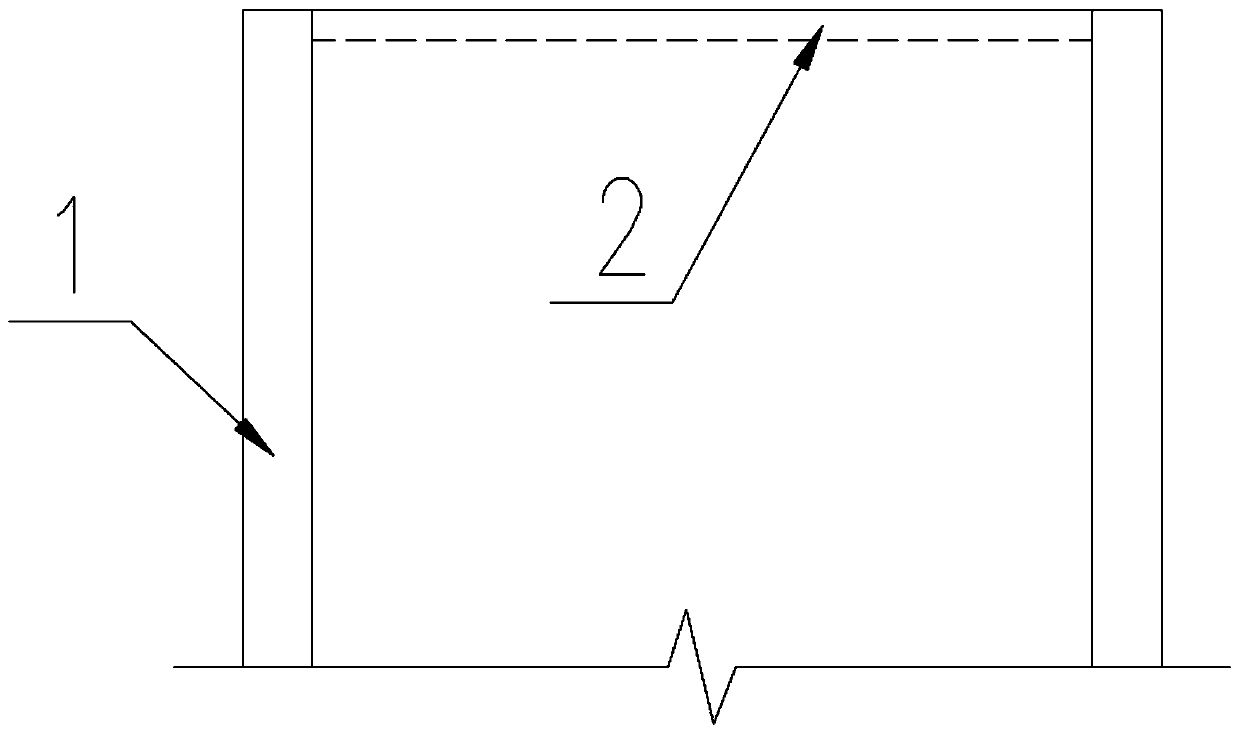

[0028] Such as Figure 1-5 As shown in the contradiction between the convenience of the existing box support construction and the welding quality, the technical solution adopted is: the slot liner node structure for the field splicing of the box support, including the lower support 1, the upper support 3. The cross sections of the lower support 1 and the upper support 3 are all box-shaped sections; the top of the lower support 1 and the bottom of the upper support 3 are oppositely welded to form a welding seam 7. An adjustable slot liner node piece is arranged in the inner cavity symmetrically, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com