A textile production line

A production line and textile technology, applied in the field of textile production equipment, can solve the problems of waste of heat energy, short life of the machine, collection, etc., and achieve the effects of reasonable structure design, production cost saving, and production income improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

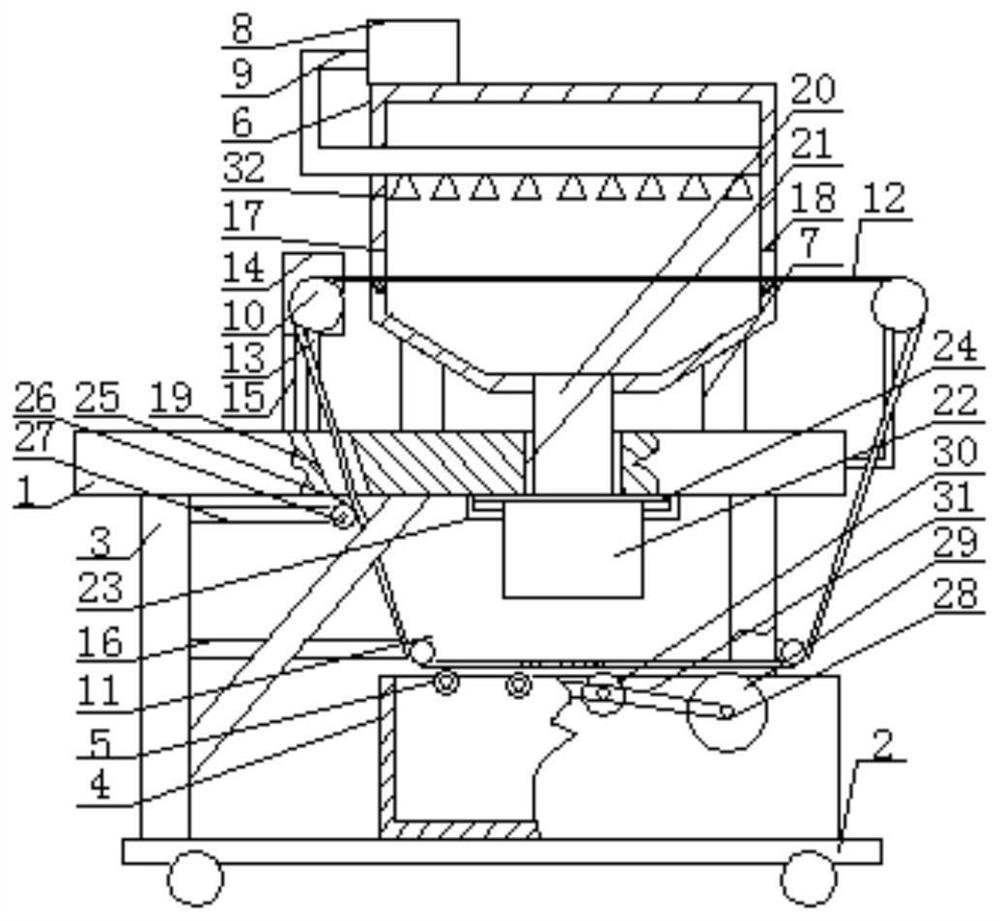

[0014] like figure 1 As shown, a textile production line specifically disclosed in this embodiment includes a workbench 1. A bottom plate 2 is provided below the workbench 1. The top surface of the bottom plate 2 is fixedly connected to the workbench 1 through several vertical rods 3. The top of the bottom plate 2 The cleaning box 4 is fixedly installed on the surface, and several cleaning hair rollers 5 are installed on the cleaning box 4. The rotating shaft of the cleaning hair rollers 5 is connected with a power device. The top of the workbench 1 is provided with a drying box 6, and the lower end of the drying box 6 is Conical, the lower end of the drying box 6 is fixedly connected to the top surface of the workbench 1 through several support legs 7, and the top surface of the drying box 6 is fixedly equipped with a hot air blower 8, and the hot air blower 8 and the drying box 6 pass through the connecting pipe 9 Connect, one end of the connecting pipe 9 is a closed end, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com