Cotton guiding device and cotton guiding method of cotton carding machine leather ring

A carding machine and apron technology, which is applied in the field of cotton apron guide device of carding machine, can solve the problems of low cotton guiding efficiency and uneven quality of cotton bundles, so as to improve efficiency, ensure normal operation, and tightly cohere Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

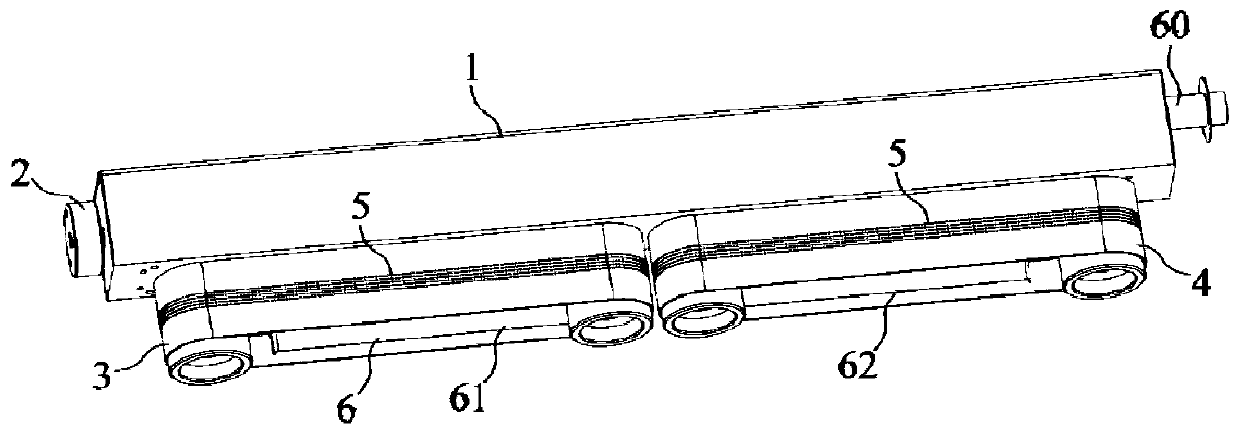

[0062] Such as figure 1 As shown, the carding machine apron cotton guide device of the present embodiment includes,

[0063] Beam 1;

[0064] a driving unit 2, which is arranged at one end of the beam 1;

[0065] The left apron 3 is connected to the driving unit 2 in a transmission manner, and the arrangement direction of the left apron 3 is the same as the length direction of the beam 1;

[0066] Right apron 4, which is connected to the left apron 3 in transmission, and the right apron 4 is arranged on the extension line of the left apron 3 in the longitudinal direction;

[0067] The transmission directions of the left apron 3 and the right apron 4 are opposite;

[0068] The middle part of the aprons of the left apron 3 and the right apron 4 are all provided with mesh holes 5, and the mesh holes 5 are arranged along the rotation direction of the corresponding apron; also include,

[0069] The air suction system 6 forms a negative pressure on the outer surface of the corre...

Embodiment 2

[0073] Such as figure 1 with figure 2 As shown, the apron cotton guide device of the carding machine of the present embodiment is further improved on the basis of Embodiment 1, and the suction system 6 includes:

[0074] Suction long pipe 60, which is a long straight tube, one end is closed, and the other port is connected with suction equipment;

[0075] The left air suction port 61, which is hollow and flat, communicates with the long air suction pipe 60, the left air suction port 61 is placed in the middle of the left apron 3, and the left air suction port 61 is close to and parallel to the left apron 3. A suction port 610 is provided on one side of the apron 3, and the suction port 610 corresponds to the position of the mesh hole 5;

[0076] The right air suction port 62 is connected in parallel with the left air suction port 60 , has the same shape and structure as the left air suction port 61 , and is placed at the corresponding position of the right apron 4 .

[007...

Embodiment 3

[0079] Such as figure 1 with figure 2 As shown, the apron cotton guide device of the carding machine in this embodiment is further improved on the basis of Embodiment 2, the crossbeam 1 is a hollow structure, and the long suction pipe 60 of the suction system 6 is placed in the In the beam 1 described above.

[0080] The crossbeam 1 of this embodiment is a hollow structure. Since the length of the long suction pipe 60 matches the length of the crossbeam 1, the long suction pipe 60 can be accommodated in the crossbeam 1, and the left suction port 61 and the right suction port 62 extend from the crossbeam 1. Placed in the corresponding apron, thus, the air suction system 6 of this embodiment can be built into the cotton guide device as a whole, without increasing the occupied space, and it is not necessary to make too many changes to other parts of the carding machine for improvement , the modification cost is small, and it is easy to use in actual production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com