A high-efficiency surface heat treatment device and heat treatment method for metal parts

A technology for surface heat treatment and metal parts, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., it can solve the problems of not being able to take pipes or solid rods at the same time, increasing the labor intensity of workers, and prolonging the working efficiency of workers. The effect of moving metal parts time, reducing labor intensity, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

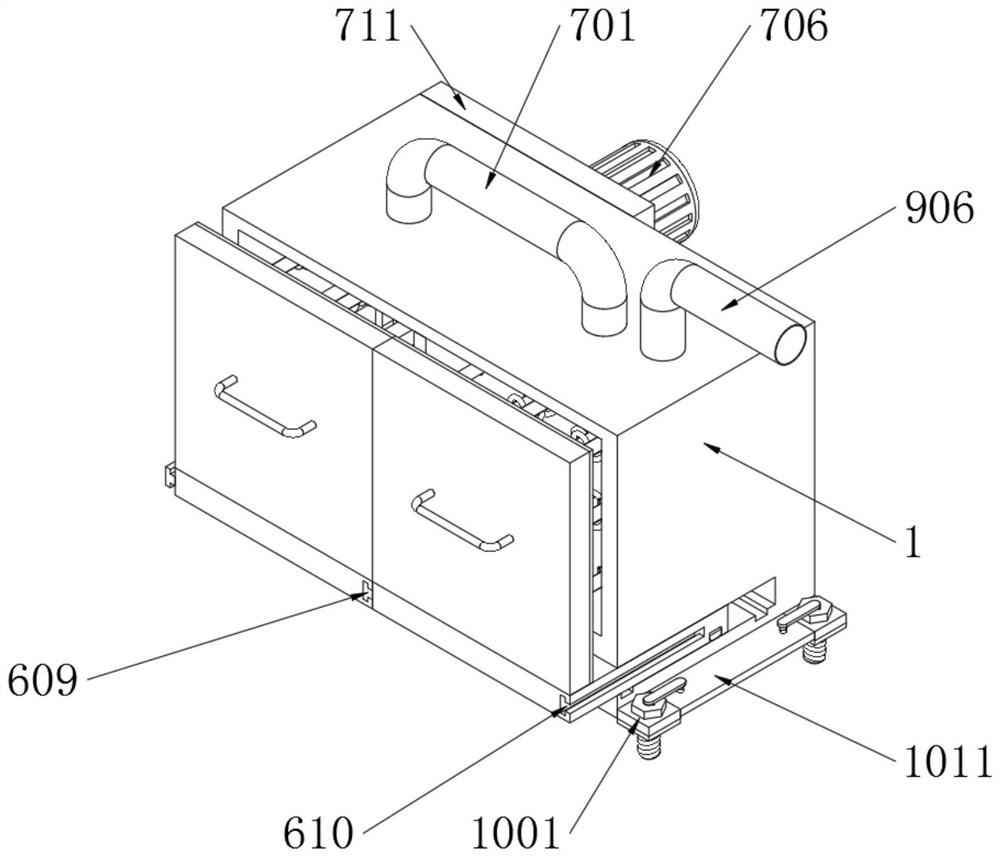

[0049] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a high-efficiency surface heat treatment device for metal parts, including a heat treatment box 1, a partition 2 is welded in the middle of the heat treatment box 1, a heating chamber 3 is formed on one side of the partition 2, and a heating chamber 3 is formed on the other side of the partition 2 A preheating chamber 4 is formed, and heating coils 5 are evenly installed on the inner wall of the heating chamber 3;

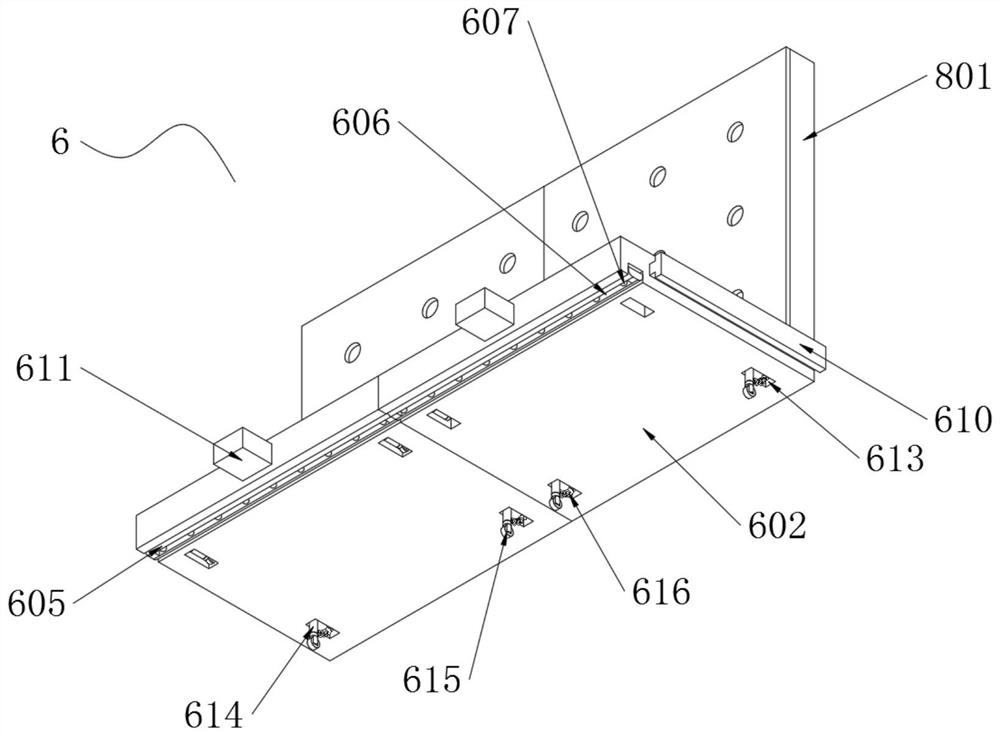

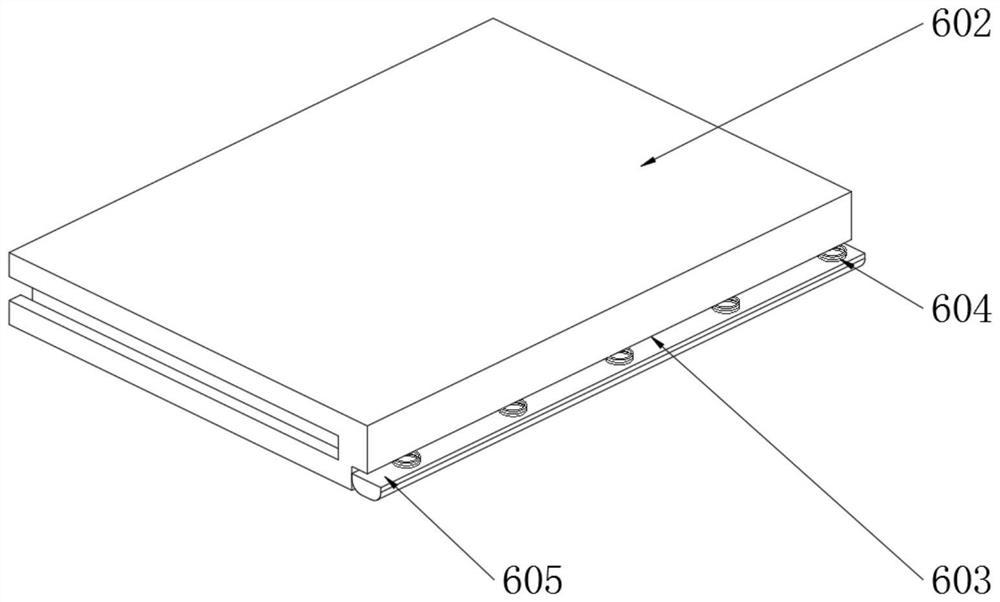

[0050] The bottom end of the heat treatment box 1 is equipped with a fetching assembly 6, which includes a moving hole 601, a push plate 602, a spring groove 603, a first spring 604, a first limit rod 605, a ball groove 606, a ball 607, and a corresponding groove 608, sliding groove 609, sliding rod 610, fixed block 611, fixing groove 612, roller groove 613, support rod 614, universal wheel 615 and second spring 616;

[0051] The bottom of the heat treatment box 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com